8

Safety Protection Measures

This product falls into Class 4 laser (marking laser) and Class 2 laser (guide laser) based on the classifications of the Safety

of laser products (JIS C 6802) / FDA standards 21 CFR 1040.10 and 1040.11/IEC60825-1.

Perform the safety protection measure shown below before using the system.

For more detail instruction, refer to each of the standard.

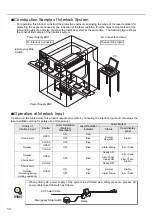

1. Construction of interlock system

In order to prevent exposure to laser beam accidentally reflected from the laser marking object or from its

circumferential areas, place a protective enclosure so that it can enclose the area in the range of laser

radiation, and construct the interlock mechanism in the system.

Additionally, install the control part that is not to exposure to the laser beam. Refer to “Construction Sample of

Interlock System” (P.14).

2. Wearing protective goggles

For protection eyes of an operator, make it mandatory to wear goggles against laser beam in the laser

controlled area.

For this product, use the laser protective goggles or glasses which meet the following requirements.

•

The goggles or glasses that have Optical Density (OD) of more than 6 at wavelength 10600nm (10.6

μ

m).

•

Through the goggles or glasses, the laser radiation indicator should be recognized.

•

ANSI Z136 and CE certified laser safety goggles or glasses

The protective goggles can momentarily protect the eyes against the scattered beam. Never look at the direct

beam or reflected beam even when the goggles are used.

3. Protective enclosure

In order to prevent exposure to laser beam accidentally reflected from the laser marking object or from its

circumferential areas, place a protective enclosure so that it can enclose the area in the range of laser

radiation.

Construct the enclosure with proper reflectance, durability and thermal resistance materials that does not

transmit a wavelength of 10600 nm (10.6

μ

m).

Recommended materials for the enclosure: metals such as iron, aluminum, stainless steel, or acrylic resins.

For acrylic plate, its thickness should be more than 3 mm and it is recommended to use the plate that has a

color to reduce the secondary radiation beam such as spark during the lasing.

Design the enclosure not to leak the laser beam from the joint parts.

Example of the joint parts:

4. Key control

In order to avoid the operation of the system by the person without authorizatio and allowance, the laser

safety manager must remove key and keep it when not in use.

•

For laser pumping is shut-off by interlock system, construct a laser re-pumping system by

manual operation for safety.

•

It is obligated by IEC/FDA/JIS that laser products shall incorporate a key-actuated master

control. Actuation of Our laser marker is basically controlled by the key switch located on the

front of the power supply box. However, in considering situations when the laser marker is

operating as a part of a larger system, the laser marker turns on if the key swith is already in ON

position, and power is supplied.

•

In this case, be sure that the external system controls the operation of the laser marker with a

key-actuated master control.

WARNING

Laser

Laser

Enclosure

Enclosure

Laser

Danger of laser exposures

Example of recommended joint design

WARNING

Summary of Contents for LP-310

Page 5: ...5 MEMO ...

Page 21: ...21 MEMO ...

Page 26: ...26 MEMO ...

Page 30: ...30 MEMO ...

Page 33: ...33 MEMO ...

Page 87: ...87 MEMO ...

Page 125: ...125 MEMO ...

Page 137: ...137 MEMO ...

Page 149: ...149 MEMO ...

Page 155: ...155 4 External Control 4 1 Control Through I O Connector 156 4 2 Control with RS 232C 166 ...

Page 186: ...186 MEMO ...

Page 187: ...187 5 Troubleshooting 5 1 Troubleshooting 188 5 2 Measures for Indicated Error 189 ...

Page 191: ...191 6 Maintenance 6 1 Maintenance 192 ...

Page 193: ...193 7 Specification 7 1 Specification 194 7 2 Outer Dimensional Drawing 195 ...

Page 197: ...197 Appendix Character Code Table 198 Readable DXF File 207 Glossary 209 ...

Page 212: ...212 Index Index 213 ...

Page 215: ...No 9000 0062 20V ...