144

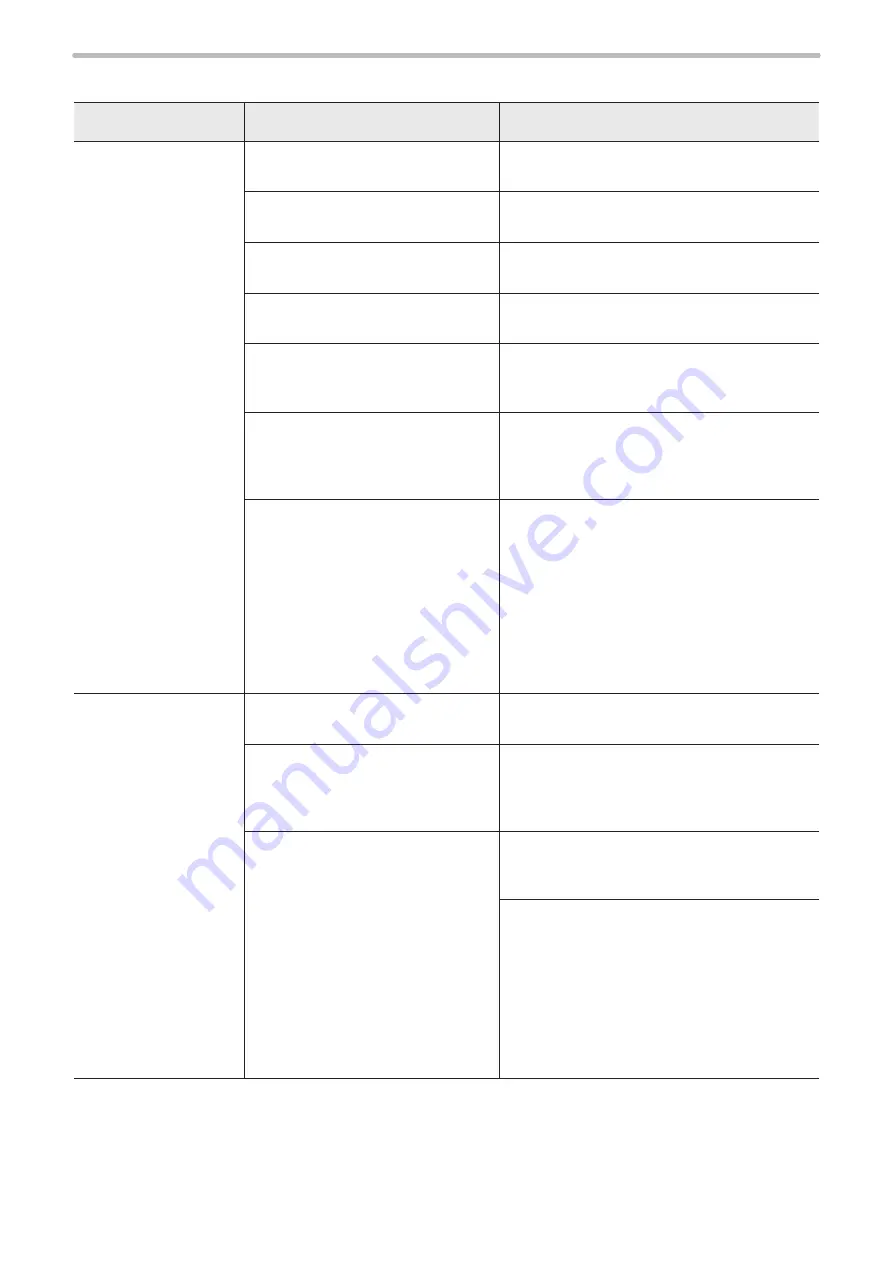

Marking

Troubles

Causes

Measures

Marking cannot be done.

(Even though the laser

radiation indicator

changes to the marking

status, nothing marked

on the object.)

Obstacle hinders laser beam.

Remove obstacle between head of laser marker

and object.

For LP-V / LP-W series:

Lens cap has not been removed.

Remove lens cap.

Distance to object is not appropriate.

Adjust distance between bottom surface of laser

maker and target surface of object as specified.

Object is not in place.

Correct position of object. Guide indication feature

may be helpful for this purpose.

The laser marker is set for the marking

on flying objects despite the static

object.

Set “Moving direction” to “STILL.” on the Trigger

Setting screen.

Laser power is insufficient.

•

Increase laser power (including correction

factor).

•

Decrease scan speed (including correction

factor).

Laser wavelength is not appropriate for

material of objects.

Materials on which can be marked differ

depending on wavelength and output power of

laser marker.

Applicable marking object is as follows;

•

FAYb laser marker (LP-V/LP-W series) : Metal,

resin (excluding transparent and translucent

types)

•

CO

2

laser marker (LP-400 series) : Resin

(including transparent and translucent types)

and paper.

Marking cannot be done.

(The laser radiation

indicator does not

change to the marking

status.)

When the marking mode is TEST:

The marking mode is “RUN”.

Select [TEST] of the marking mode.

When the marking mode is RUN:

The run mode is not started or the

marking trigger is not input.

Set the marking mode into [RUN] and press

[Start].

Then, input the marking trigger from [TRIG. IN]

signal on the I/O terminal.

When the laser marker is under the

remote mode or run mode:

Marking trigger signal is not input.

Check connections with external equipment for

mis-connection, disconnection or contact failure

due to any loose connector.

When the marking trigger is input from the I/O

terminal, check if marking trigger signal meets

write conditions.

•

For Trigger Marking:

Check if one-shot signal of 10 ms or longer is

provided per marking cycle.

•

For Equidistant Marking:

Check if status of the signal remains on during

marking.

ME-LP400V-EX-6

Summary of Contents for LP-400 Series

Page 12: ...1 Before External Control ME LP400V EX 6...

Page 24: ...2 Control by I O ME LP400V EX 6...

Page 56: ...3 Control by Serial Communication RS 232 Ethernet ME LP400V EX 6...

Page 141: ...Troubleshooting ME LP400V EX 6...

Page 158: ...Character Code Table ME LP400V EX 6...

Page 176: ...Index ME LP400V EX 6...

Page 179: ...No 9000 0062 17V...

Page 180: ...Panasonic Industrial Devices SUNX Co Ltd 2003 2018 July 2018 9000 0062 17V...