44

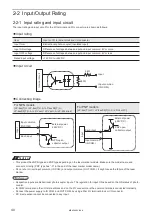

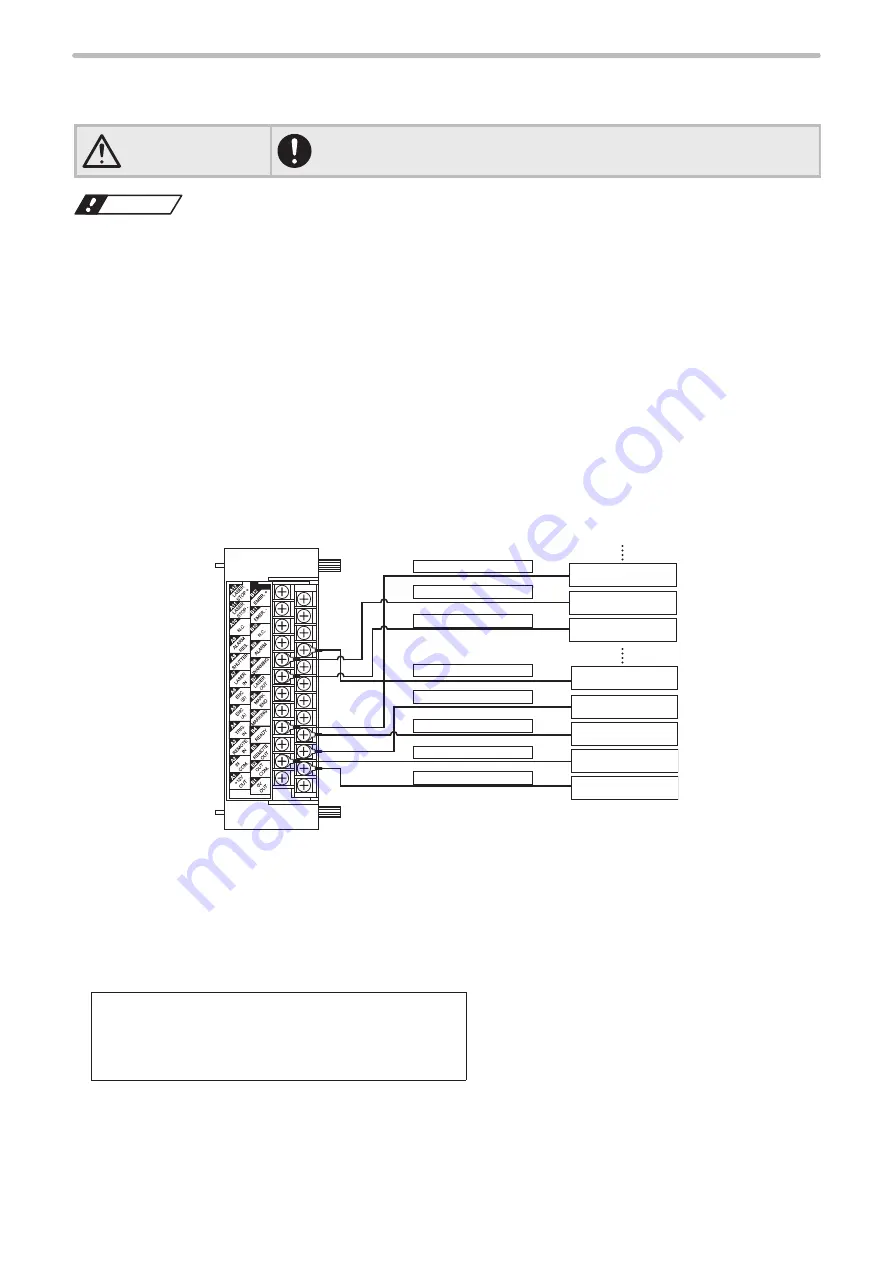

2-3-2 Connecting sample with external devices

This paragraph exemplifies a basic interface sample with external device such as a PLC.

CAUTION

•

Make sure that the power is turned OFF at wiring.

Notice

•

Short-circuiting IN COM. and OUT COM. in supplying power might cause the short out and also cause the failure of the

laser marker. Please make sure to check the power wiring before running the laser marker.

•

IN COM. and OUT COM. on the I/O connector are connected with IN COM. and OUT COM. on the Input/Output terminal

respectively and internally. Therefore, inverting the power supply wiring might cause a short circuit, resulting in the

failure of the laser marker.

•

Do not apply the voltage exceeding the maximum applied voltage, or devices may be broken.

•

Do not apply the electric current for input (output) terminal exceeding the maximum output current, or devices may be

broken.

•

When the terminal block is connected with the external power supply, do not use A1 [+12V OUT] and B1 [0V OUT] of I/O

terminal block. If a short bar is installed, remove it.

⿎

Connecting sample for NPN models (Controlled by external devices)

[LP-4xx(T)U / LP-4xx(T)U-A / LP-4xxS9(T)U / LP-4xxS9(T)U-A / LP-VxxU / LP-VxxU-A /

LP-W series]

A7 :LASER IN

B2 :OUT COM

A2 :IN COM.

A4 :TRIG.IN

PLC

B3 :REMOTE OUT

B9 :ALARM

A8 :SHUTTER

B4 :READY

0V

24V

Terminal Block

Output (Y2)

Input (X2)

Input (X1)

Input (X0)

Output (Y1)

Output (Y0)

•

When laser marker is controlled by the external device such as PLC, connect A2 [IN COM.] to the external power (+),

and B2 [OUT COM.] to the external power (-) for NPN type laser marker.

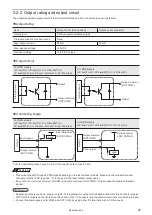

•

Connect B12 [EMER.+] to B11 [EMER.-] to release the emergency stop function. (Opening between B12 - B11 turns off

the laser pumping and marking is disabled.)

•

Connect A12 [LASER STOP +] to A11 [LASER STOP -] to release laser stop function. (Opening between A12 - A11

closes the auto-shutter, and changes the status of the device into invalid for marking.)

•

At the factory shipments, the following terminals are already short-circuited by short bars. When connecting to any

external devices, remove the short bar(s) from the terminals to be used, to connect the devices.

A1 [+12V OUT]

―

A2 [IN COM.]

B1 [0V OUT]

―

B2 [OUT COM.]

B12 [EMER. +]

―

B11 [EMER. -]

A12 [LASER STOP +]

―

A11 [LASER STOP -]

•

“Output simulation” and “I/O check monitor” can simulate ON/OFF state on each connector. Please use these functions

in checking the wiring. Refer to the Operation/Maintenance Manual.

ME-LP400V-EX-6

Summary of Contents for LP-400 Series

Page 12: ...1 Before External Control ME LP400V EX 6...

Page 24: ...2 Control by I O ME LP400V EX 6...

Page 56: ...3 Control by Serial Communication RS 232 Ethernet ME LP400V EX 6...

Page 141: ...Troubleshooting ME LP400V EX 6...

Page 158: ...Character Code Table ME LP400V EX 6...

Page 176: ...Index ME LP400V EX 6...

Page 179: ...No 9000 0062 17V...

Page 180: ...Panasonic Industrial Devices SUNX Co Ltd 2003 2018 July 2018 9000 0062 17V...