140

5.

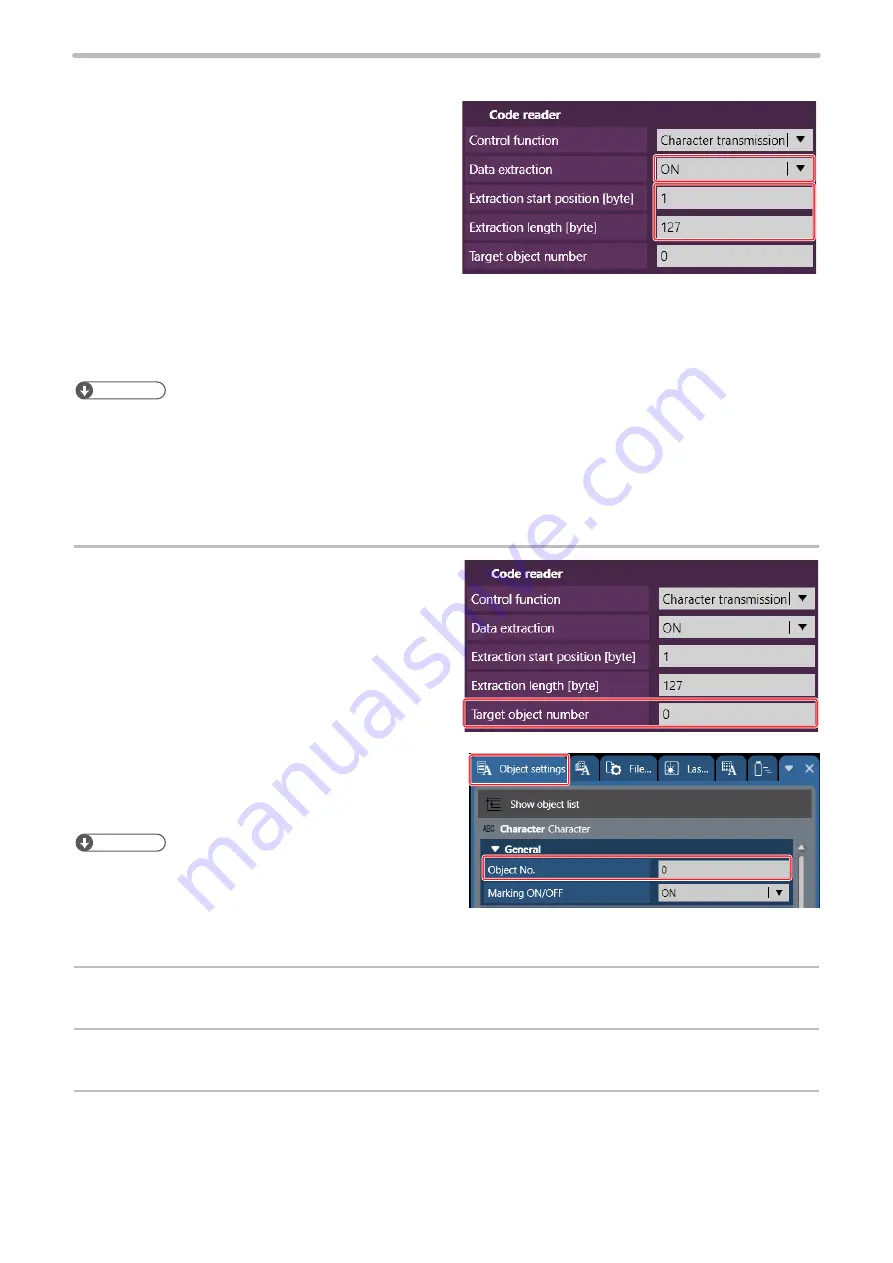

To transfer a part of the code string read, set the data extraction.

If “OFF” is selected, the read string is transmitted as is.

To set the data extraction, specify the start position

and data length of the code data in bytes.

Setting range:

• Extraction start position: 1 to 299 byte

• Extraction length

• Character transmission: 1 to 299 byte

• File switching by name: 1 to 299 byte

• File switching by number: 4 byte (fixed)

Extraction example: To read code characters “ABCDE” and transfer “BCD” to the laser marker, set as follows:

• Extraction start position [byte]: 2

• Extraction length [byte]: 3

ンㄆㄇㄆㄓㄆㄏㄆ

• Count one single byte character as one byte.

• The data extraction position setting applies to all data read by this function.

• If the read data length is shorter than the string to extract, the code is not read.

• Set the checksum setting of the code reader RS-232C communication settings to “OFF”. If the checksum is set to “ON”,

the communication checksum is transferred to the laser marker as marking data.

• The end code (CR) is not subject to the data extraction.

6.

If the control contents are set to character

data transmission, specify the object number

of destination.

The read character data are transmitted to the object

number specified here.

Check the file to use this function and specify an

appropriate object number.

Object numbers available as object numbers of

destination are as follows.

• Object numbers for which character object is set

• Object numbers for which a bar code or 2D code

object is set

ンㄆㄇㄆㄓㄆㄏㄆ

• If there is not object number set as a object number of

destination other than a character in the file to use this

function or code is set for the number, character data

cannot be transmitted.

7.

Click “Set” in the lower right corner of the system settings screen.

8.

Disconnect the online connection with the laser marker.

9.

Turn off the laser marker power and wait for five seconds or more, then restart.

The configured items will be reflected to the laser marker.

ME-LPGS-SM-8

Summary of Contents for LP-GS Series

Page 17: ...1 Product Overview ME LPGS SM 8 ...

Page 32: ...2 Laser Marker Installation ME LPGS SM 8 ...

Page 48: ...3 Operation Method ME LPGS SM 8 ...

Page 68: ...4 External Control Using I O ME LPGS SM 8 ...

Page 107: ...5 External Control by Communication Commands ME LPGS SM 8 ...

Page 116: ...6 Link Control with External Devices ME LPGS SM 8 ...

Page 141: ...7 Maintenance ME LPGS SM 8 ...

Page 161: ...161 MEMO ME LPGS SM 8 ...

Page 162: ...Troubleshooting ME LPGS SM 8 ...

Page 186: ...Index ME LPGS SM 8 ...

Page 189: ......

Page 190: ... Panasonic Industrial Devices SUNX Co Ltd 2014 2019 April 2019 ...