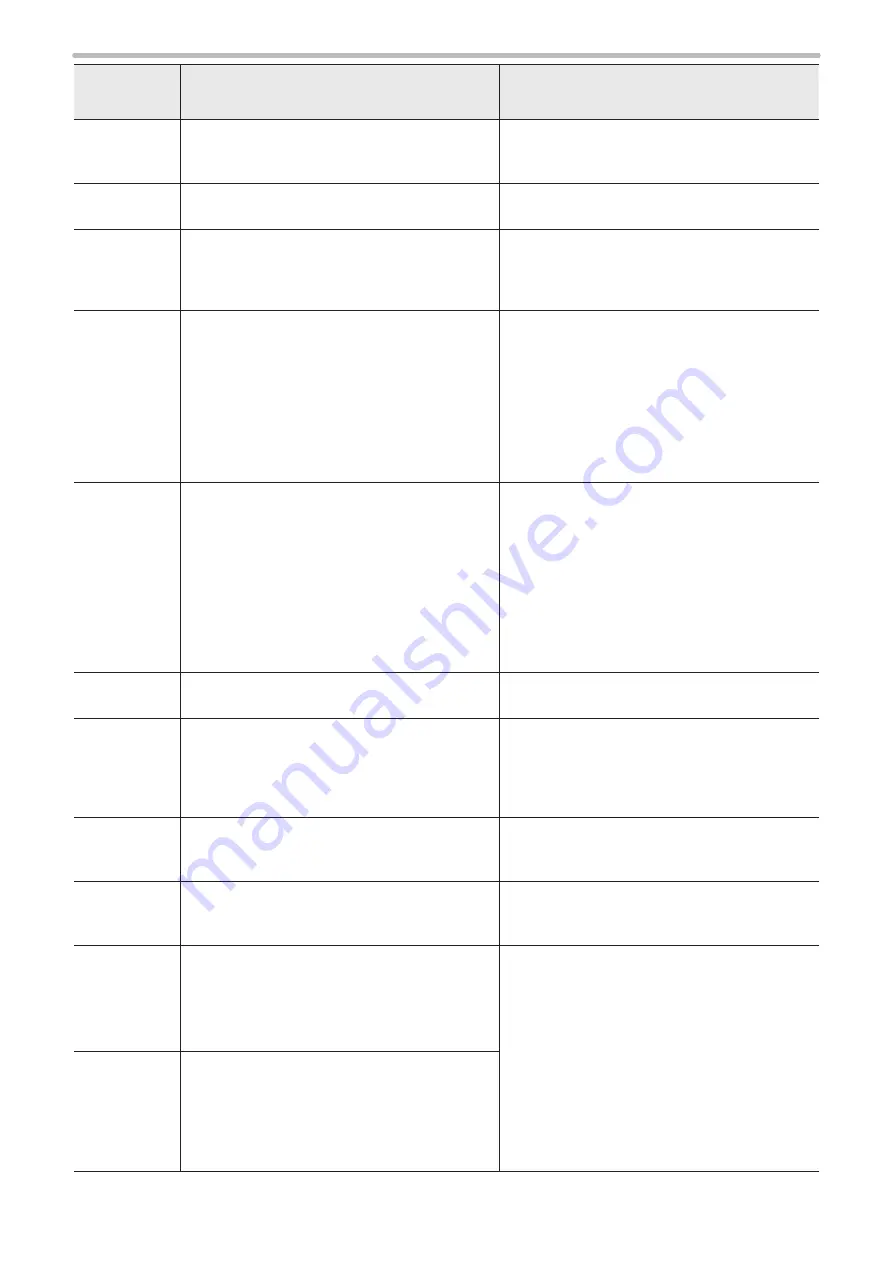

174

ERROR

CODE

Description

Measures *1

E205 - E207

• Abnormality occurs on the internal shutter.

• Signal cable is not connected properly.

Check the connection of the cable and various

signal lines, and then restart the laser marker.

E220

Laser head housing is open.

Contact our sales office or representatives.

E225 *4

Fiber unit is detached.

Install the fiber unit properly by following the

procedures described in the Setup/Maintenance

Guide.

E250 - E252

E260 - E261

E264 - E265

• An error has occurred to the laser oscillator.

• A power supply voltage error was detected in

the laser oscillator.

• Incorrect connection of signal cable or unit

power cable.

• Check and correct the power status.

• Check if the AC power line is effected by noise.

• Check the connection of the cable and various

signal lines, and then restart the laser marker.

• For LP-RC series:

Check if the ambient temperature of the

laser marker is not exceeding the range of its

specification.

E262 *4

Temperature error in laser oscillator.

• Check if the ambient temperature of the

laser marker is not exceeding the range of its

specification.

• Make sure air-cooling fan operates.

• Remove the dust and contamination in the

air intake and exhaust port, and clean the air-

cooling part such as fan and filter.

• When not recovered, contact our sales office

or representatives.

E263 *4

Detected unintended-irradiation.

Contact our sales office or representatives.

E270 - E275

E277

E280 - E285

E287

• An error has occurred to the galvano scanner

of the head.

• Incorrect connection of signal cable or unit

power cable.

• Check and correct the power status.

• Check if the AC power line is effected by noise.

• Check the connection of the cable and various

signal lines, and then restart the laser marker.

Marking data are too detailed for the scan speed

configured.

Decrease the scan speed.

E290 - E291

*2

An error has occurred to the Z-axis adjustment

module.

Check the connection of the cable and various

signal lines, and then restart the laser marker.

E400

INTERLOCK 1 of the I/O terminal block was

released.

• Connect INTERLOCK terminals on the I/O

terminal block.

• Check the status of the safety equipment

connected to INTERLOCK terminal.

• Confirm operation logic of connection device.

• For LP-RC/LP-RF/LP-RV series:

If the error cannot be solved even with the

proper connection of INTERLOCK terminals,

replace the contactor for INTERLOCK by

following the procedures described in the

Setup/Maintenance Guide.

E401

INTERLOCK 2 of the I/O terminal block was

released.

ME-LPGS-SM-8

Summary of Contents for LP-GS Series

Page 17: ...1 Product Overview ME LPGS SM 8 ...

Page 32: ...2 Laser Marker Installation ME LPGS SM 8 ...

Page 48: ...3 Operation Method ME LPGS SM 8 ...

Page 68: ...4 External Control Using I O ME LPGS SM 8 ...

Page 107: ...5 External Control by Communication Commands ME LPGS SM 8 ...

Page 116: ...6 Link Control with External Devices ME LPGS SM 8 ...

Page 141: ...7 Maintenance ME LPGS SM 8 ...

Page 161: ...161 MEMO ME LPGS SM 8 ...

Page 162: ...Troubleshooting ME LPGS SM 8 ...

Page 186: ...Index ME LPGS SM 8 ...

Page 189: ......

Page 190: ... Panasonic Industrial Devices SUNX Co Ltd 2014 2019 April 2019 ...