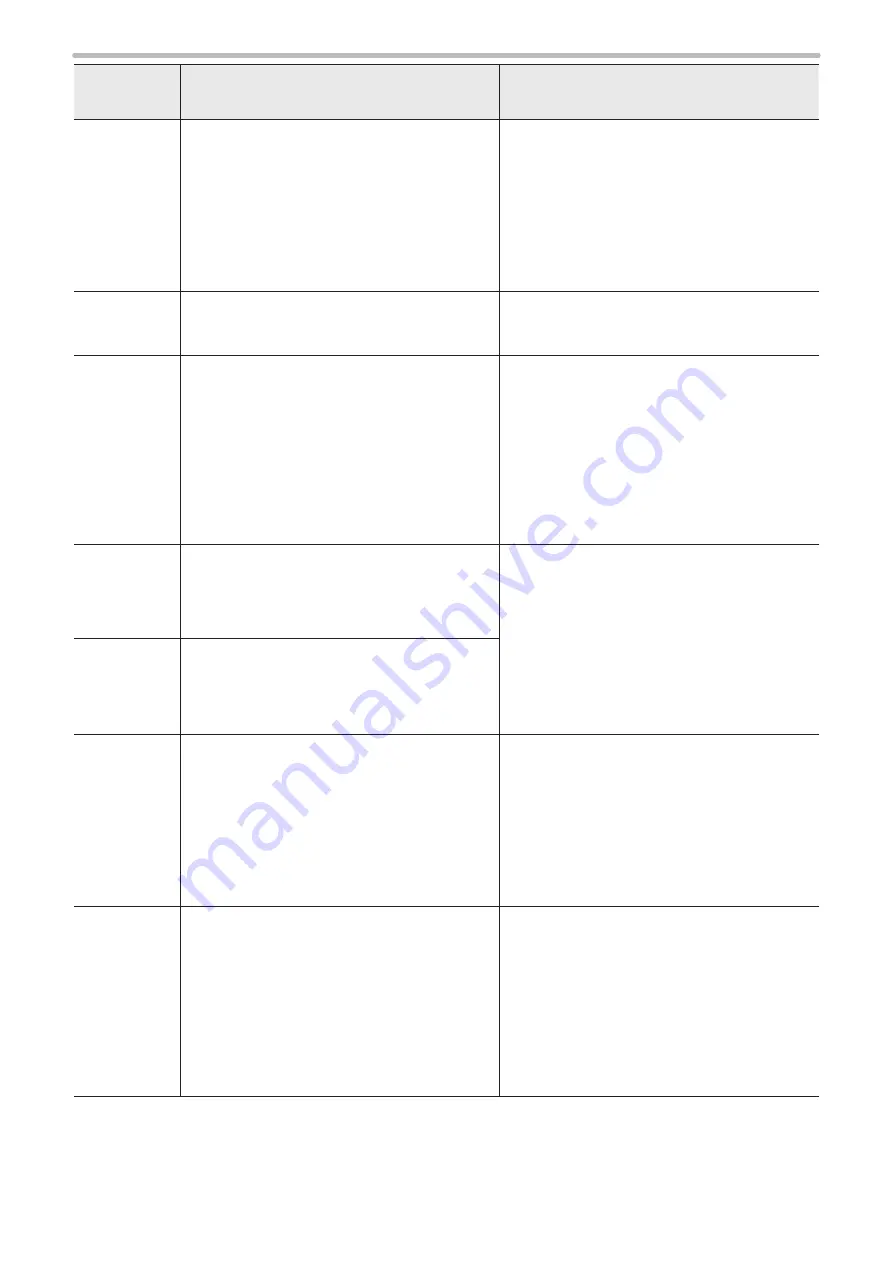

175

ERROR

CODE

Description

Measures *1

E402

E403

E501

LASER STOP IN of the I/O terminal block was

released.

• Connect the LASER STOP IN terminals of the

I/O terminal block.

• Check the status of the safety equipment

connected to the LASER STOP IN terminals.

• Confirm operation logic of connection device.

• Connect the internal or external power supply

to IN COM.1 and OUT COM.1 in the I/O

terminal respectively.

E404

E502

The stop laser button of the Laser Marker NAVI

smart was pressed.

Press the stop laser button of Laser Marker NAVI

smart to release.

REMOTE INTERLOCK IN is open.

• Connect REMOTE INTERLOCK IN of the I/O

terminal block.

• Check the status of the safety equipment

connected to REMOTE INTERLOCK IN

terminal.

• Confirm operation logic of connection device.

• Connect the internal or external power supply

to IN COM.1 and OUT COM.1 in the I/O

terminal respectively.

E410

Laser pumping was stopped during the marking

process.

• Start marking after laser pumping has

completed.

• Check the procedures and operation logic of

laser pumping and trigger input control.

• Check wiring of I/O or communication port to

the external control devices.

• Check the switch or the sensor connected to

TRIGGER IN of I/O terminal operates properly

without chattering.

E411

E500

The marking trigger signal or “Start marking”

button was entered in the “laser pumping OFF”

status.

E450 - E453

• The date and time of the system clock may be

out of synchronization.

• The system clock battery power in the

controller died.

• Abnormality has occurred on the system clock

in the controller.

• Check the system clock time and set it again.

• Replace the internal battery by following the

“Replacement of Internal Controller Battery” in

the Setup/Maintenance Guide.

• While laser marker power is on, you can use

it after setting the system clock on the system

settings screen. When the power is off, set the

system clock again.

E460 *2

Temperature error in laser oscillator.

• Check if the ambient temperature of the

laser marker is not exceeding the range of its

specification.

• Make sure air-cooling fan operates.

• Remove the dust and contamination in the

air intake and exhaust port, and clean the air-

cooling part such as fan and filter.

• When not recovered, contact our sales office

or representatives.

ME-LPGS-SM-8

Summary of Contents for LP-GS Series

Page 17: ...1 Product Overview ME LPGS SM 8 ...

Page 32: ...2 Laser Marker Installation ME LPGS SM 8 ...

Page 48: ...3 Operation Method ME LPGS SM 8 ...

Page 68: ...4 External Control Using I O ME LPGS SM 8 ...

Page 107: ...5 External Control by Communication Commands ME LPGS SM 8 ...

Page 116: ...6 Link Control with External Devices ME LPGS SM 8 ...

Page 141: ...7 Maintenance ME LPGS SM 8 ...

Page 161: ...161 MEMO ME LPGS SM 8 ...

Page 162: ...Troubleshooting ME LPGS SM 8 ...

Page 186: ...Index ME LPGS SM 8 ...

Page 189: ......

Page 190: ... Panasonic Industrial Devices SUNX Co Ltd 2014 2019 April 2019 ...