140

⿎

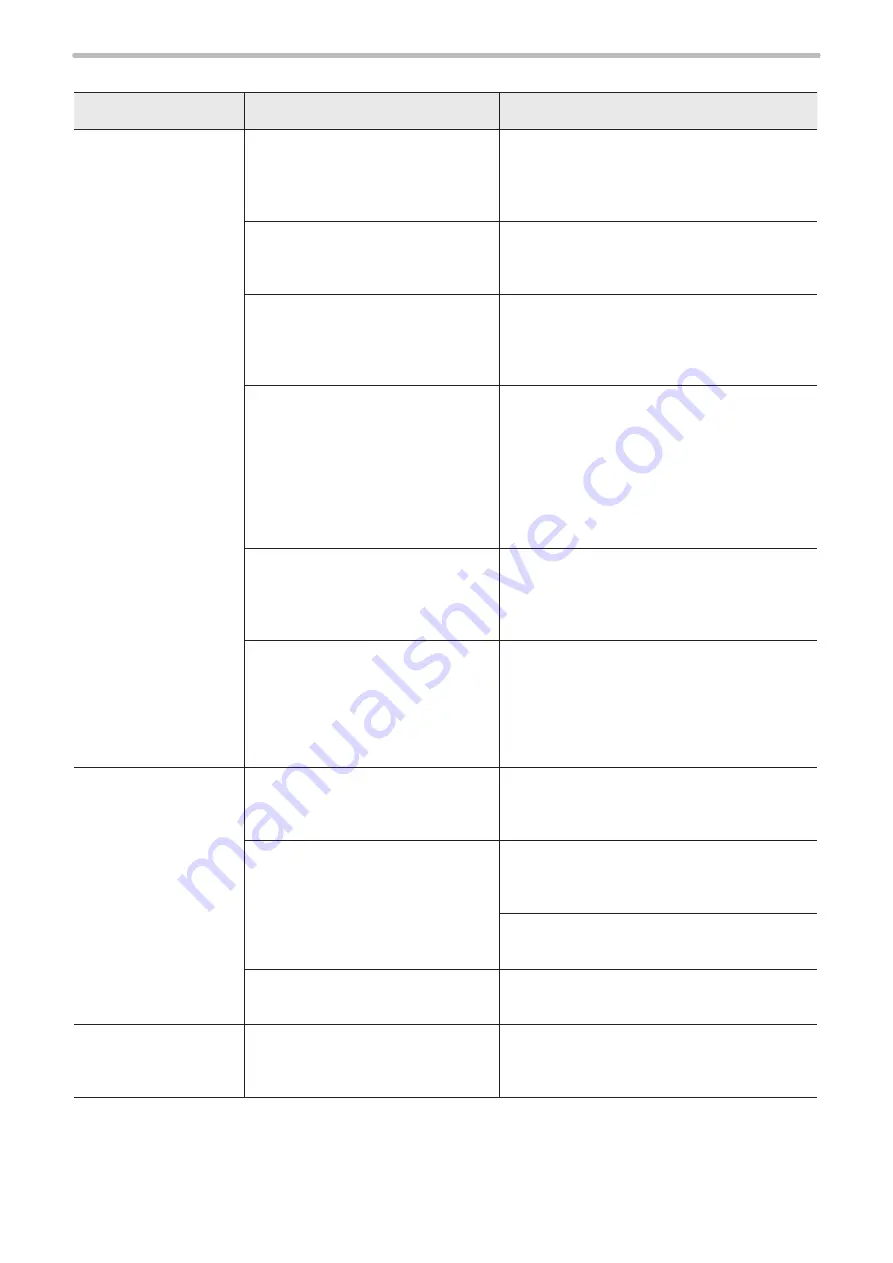

Lasing operation

Troubles

Causes

Measures

Marking cannot be done.

(The laser emission

indicator blinks but

marking is not performed

on the work piece.)

Obstacle hinders laser beam.

• Remove obstacle between laser emission port

of laser marker head and work piece.

• For LP-RF/LP-RV series, remove the

protection cap of the laser emission port.

Distance to work piece is not

appropriate.

Adjust distance between bottom surface of laser

marker head and the work piece surface as

specified.

For LP-GS series:

The set Z-position does not match the

height of the actual target object.

(The LP-GSxxx-L type is excluded.)

Set the Z-position according to the work piece

height.

The work piece is not in place.

• Check the marking position using the guide

laser or guide pointer to check if the work piece

is out of the specified position.

• For LP-RC/LP-RF/LP-RV series:

Connecting a sensor to TARGET DETECTION

IN (X7) of I/O terminal block, you can check

the presence of the work piece during laser

radiation.

Laser power is insufficient.

• Increase laser power (including correction

factor).

• Decrease scan speed (including correction

factor).

Laser type (wavelength, output power,

etc.) is not appropriate for material of

the work piece.

Materials can be marked differ depending on

wavelength and output power of laser marker.

• LP-GS/LP-RC is not suitable for metal

material.

• LP-RF/LP-RV is not suitable for transparent

material.

Marking is not performed

in RUN/REMOTE mode.

(The laser emission

indicator does not light.)

In RUN mode:

The RUN Mode is not active or the

marking start signal is not input.

Turn the RUN mode ON, and then input a signal

to TRIGGER IN of the I/O terminal block.

The marking trigger signal of the I/O

terminal block is not input.

Check connections with external equipment for

mis-connection, disconnection or contact failure

due to any loose connector.

Confirm that TRIGGER IN is input by one-shot

signal of more than 2ms per marking cycle.

The marking trigger is entered while

the marking ready is OFF.

Refer to “External Control” in Troubleshooting.

Sometimes laser is

emitted unintentionally.

Fumes causes malfunction of

photoelectric sensor for marking trigger

signal.

• Install a dust collector to eliminate the fume

(gas) generated during lasing.

• Check that dust collector works well.

ME-LP-GS-SR-COMP-3

Summary of Contents for LP-GS Series

Page 11: ...1 Preparation of Command Control ME LP GS SR COMP 3...

Page 26: ...2 Communication Control Basics ME LP GS SR COMP 3...

Page 50: ...3 Data Format for Each Command ME LP GS SR COMP 3...

Page 136: ...136 MEMO ME LP GS SR COMP 3...

Page 137: ...Troubleshooting ME LP GS SR COMP 3...

Page 163: ...Character Code Table ME LP GS SR COMP 3...

Page 176: ...Index ME LP GS SR COMP 3...

Page 178: ...178 W Warning 154 ME LP GS SR COMP 3...

Page 179: ......

Page 180: ...Panasonic Industrial Devices SUNX Co Ltd 2014 2019 April 2019...