166

Troubleshooting

If any operation errors occur, check items below.

When the problems cannot be resolved by following the below measures, please contact our sales office.

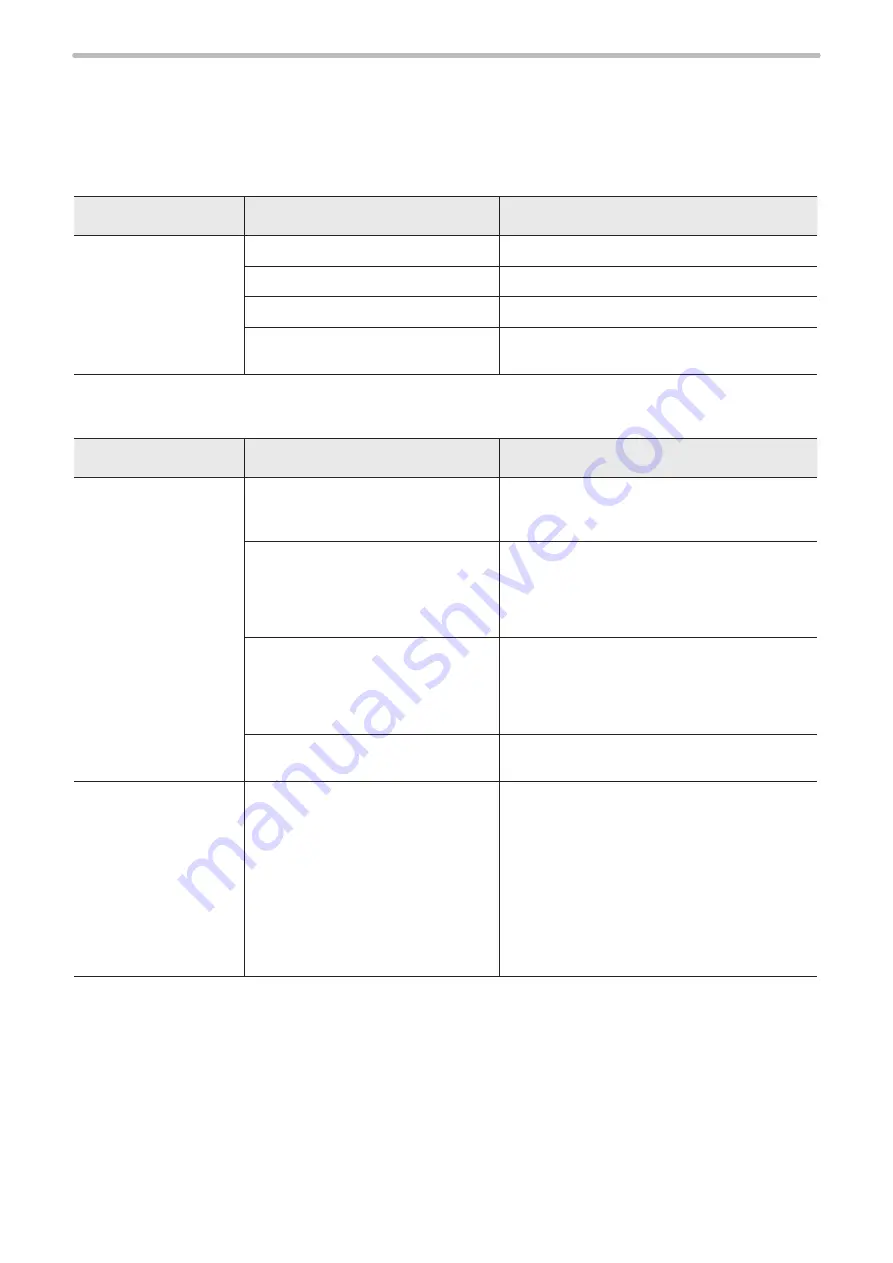

Start-up

Troubles

Causes

Measures

Power supply is not

turned on.

The unit does not start

up.

Power cable is not connected.

Connect the power supply cable.

Key switch is not turned on.

Turn on the key switch.

Power is not supplied.

Check the power supply.

Fuse is blown.

Replace the fuse by following the “Safety / Setup

/ Maintenance Guide”.

Laser pumping

Troubles

Causes

Measures

Laser is not pumped.

[IN COM.] [OUT COM.] of terminal

block is not connected to the power

supply.

Connect [IN COM.] and [OUT COM.] in Input/

Output Terminal to internal power supply or

supply power from outside.

The interlock connector is not

connected, or the safety equipment

such as door and switch connected

to the interlock connector is in OPEN

status.

•

Check the interlock connector connection.

•

Restore the original condition of the safety

equipment connected to the interlock

connector.

Laser stop 2 on input terminal is in

OPEN status, or safety equipment

such as door and switch connected to

the laser stop 2 on input terminal is in

OPEN status.

•

Check the connection of [LASER STOP 2A],

[LASER STOP 2B] and [OUT COM] of input

terminal.

•

Restore the original condition of the safety

equipment connected to the laser stop 2.

Emergency stop switch is pressed.

(Except for -LS1 models)

Reset emergency stop switches located on the

controller.

Laser is not pumped in

remote mode.

Laser pumping ON signals from the

external control equipment are not

input or not accepted in remote mode.

•

Check connections with external equipment

for mis-connection, disconnection or contact

failure due to any loose connector.

•

When controlling the laser pumping by I/O

signal, turn off DIP switch No. 2 and turn on

[LASER IN].

•

When controlling the laser pumping by serial

communication, turn on DIP switch No. 2 and

transmit the laser pumping command (LSR).

•

To change the DIP setting, the switch of the

laser marker should be set at power OFF state.

ME-LPMSZ-SR-9

Summary of Contents for LP-M Series

Page 8: ...1 Before External Control ME LPMSZ SR 9...

Page 16: ...2 Basics of Serial Communication RS 232 Ethernet ME LPMSZ SR 9...

Page 34: ...3 Communication Command and Function ME LPMSZ SR 9...

Page 165: ...Troubleshooting ME LPMSZ SR 9...

Page 186: ...Character Code Table ME LPMSZ SR 9...

Page 199: ...Index ME LPMSZ SR 9...

Page 202: ...202 MEMO No 9000 0063 59V ME LPMSZ SR 9...

Page 203: ...No 9000 0063 59V...

Page 204: ...Panasonic Industrial Devices SUNX Co Ltd 2013 2019 March 2019 9000 0063 59V...