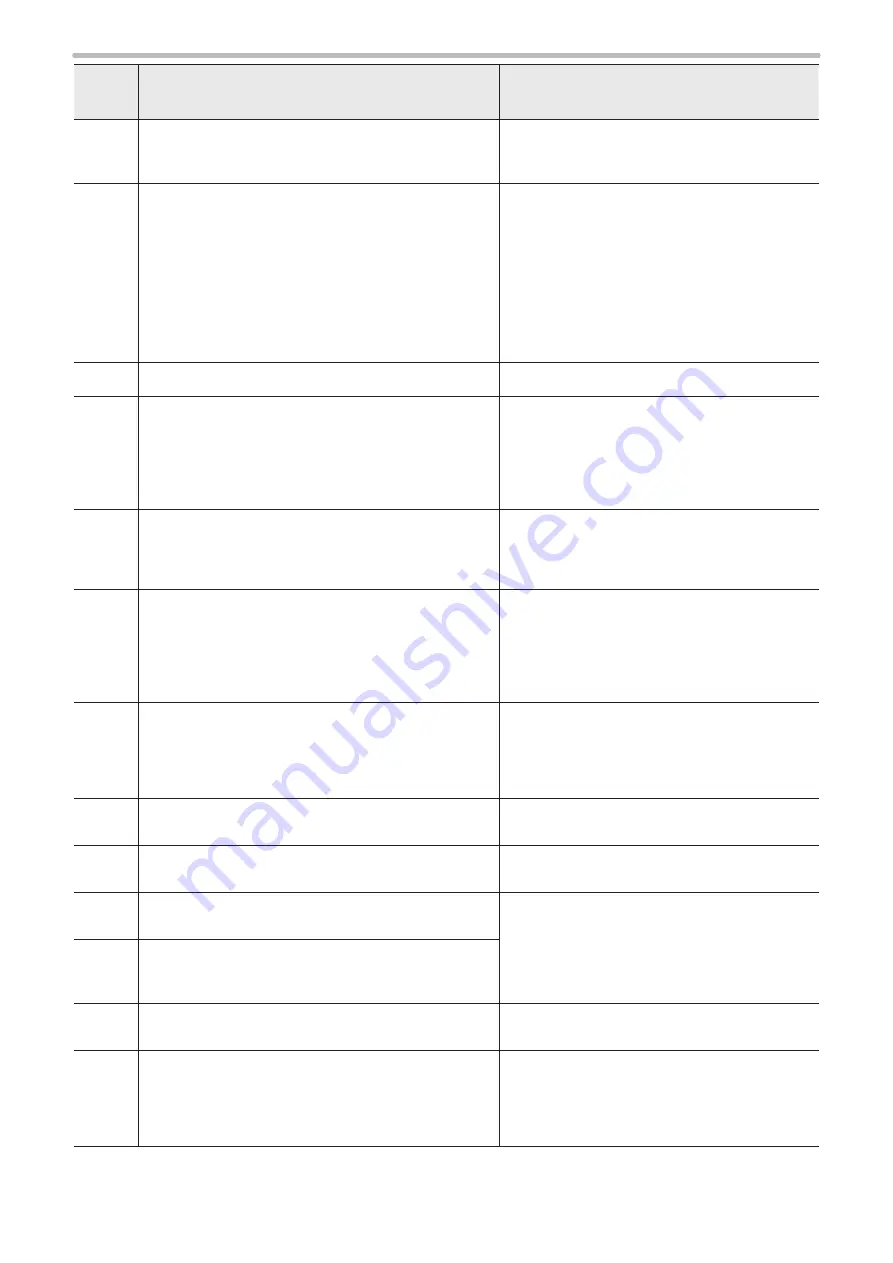

162

ERROR

CODE

Error description

Measures

E220

Internal shutter error.

• Connect signal cable properly, and restart with

key switch.

• Contact to our sales office.

E233

Laser error.

• The internal temperature of the laser oscillator

exceeds the limit.

• Instantaneous interruption of laser power supply is

detected.

• Signal cable is not connected properly.

• Fiber is broken.

• The abnormality of the laser oscillator is confirmed.

• There might be occurred the malfunction of the

internal shutter.

• Check that the ambient temperature is in the

specified operating temperature.

• Check the air filter, the air intake / exhaust port

and the fan of the cooling part for clogging.

• Check and correct the power status.

• Check the noise influence to the AC power

supply from the other devices.

• Connect the unit power cable and the signal

cable properly, and restart with key switch.

• When not recovered, contact our sales office.

E234

Detected unintended- irradiation.

Contact to our sales office.

E236

Laser gate is not open, or laser error has occurred.

• Check the control signal for opening/closing

the laser gate from the safety PLC or other

such device.

• Check the wiring and signal timing of [L-GATE

CL IN] of the laser gate terminal.

• Refer to the measure of E233 “Laser error”.

E240

E241

The temperature of the laser has reached its limit.

• Check that the ambient temperature is in the

specified operating temperature.

• Make sure cooling fan operates.

• When not recovered, contact our sales office.

E250

Detected a decrease in power supply voltage.

• Check and correct the power status.

• Check the noise influence to the AC power

supply from the other devices.

• Connect unit power cable properly, and restart

with key switch.

• When not recovered, contact our sales office.

E260

Interlock connector is opened.

Test marking starts while interlock connector on

controller is in OPEN status.

Interlock on controller is in OPEN status. (in remote

status)

• Check wiring of the interlock input on the

controller and contact of the switch.

• Confirm operation logic of connection device.

• Connect the interlock connector with the non-

voltage contact.

E280

System error.

• Z control module error.

Restart the laser marker. When not recovered,

contact to our sales office.

E300

A head is not connected. Shut off a power and connect a

head.

Connect signal cable properly, and restart with

key switch.

E310

Unsupported head.

Change either head or controller.

• Connect signal cable properly, and restart with

key switch.

• Check if head with correct model has been

connected. If it is wrong, replace head or

controller with correct one.

E311

System error.

• Signal cable is not connected properly.

• Wrong head has been connected to controller.

E312

System error.

Restart the laser marker. When not recovered,

contact to our sales office.

E320

Unit combination is incorrect.

• Connect signal cable properly, and restart with

key switch.

• Check if head with correct model has been

connected. If it is wrong, replace head or

controller with correct one.

ME-LPM-SSM-10

Summary of Contents for LP-M Series

Page 16: ...16 MEMO ME LPM SSM 10...

Page 27: ...27 Chapter 1 Specification ME LPM SSM 10...

Page 37: ...37 Chapter 2 Preparation ME LPM SSM 10...

Page 69: ...Chapter 3 Connection for External Control ME LPM SSM 10...

Page 128: ...Chapter 4 Maintenance ME LPM SSM 10...

Page 148: ...Troubleshooting ME LPM SSM 10...

Page 169: ...Index ME LPM SSM 10...

Page 172: ...172 MEMO No 9000 0066 34V ME LPM SSM 10...

Page 173: ...No 9000 0066 34V...