153

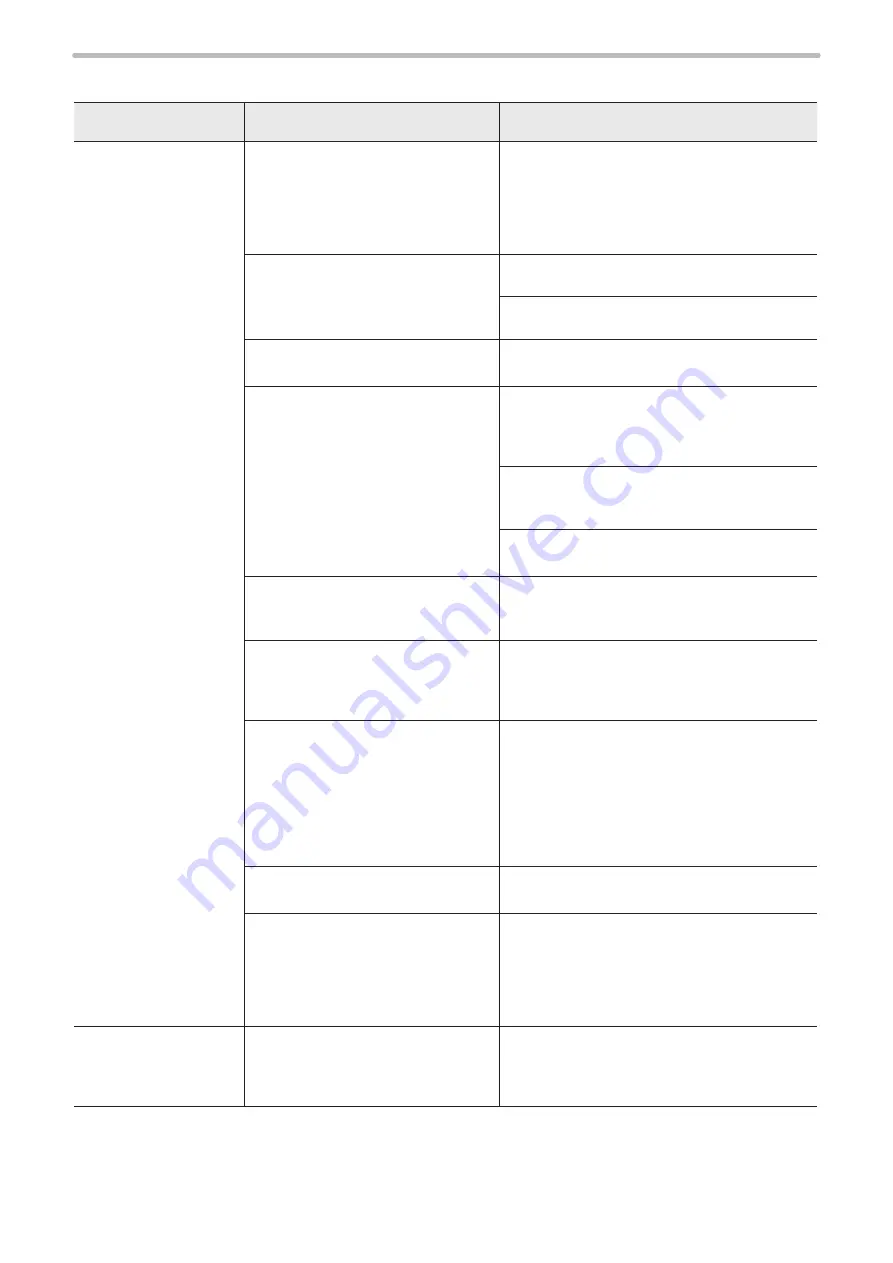

Marking quality

Troubles

Causes

Measures

Marking fades entirely/

partially.

Laser emission port is not clean.

Refer to the “Safety / Setup / Maintenance Guide”

“Maintenance” and clean contaminants off the

laser emission port.

If contaminants persist, replace lens and/or laser

emission port protection cover (glass). Contact

our sales office.

Fumes occurring during marking hinder

laser beam.

Install dust collector.

Check that dust collector works well.

Distance to object is not appropriate.

Adjust distance between bottom surface of laser

maker and target surface of object.

For LP-M series:

The displacement sensor input does

not match the distance to the actual

marking surface.

Confirm the displacement sensor and laser

marker input specifications and adjust the

displacement sensor output (analog current value)

to a suitable value.

Input the displacement sensor trigger when the

displacement sensor measurement value is

steady.

Match the displacement sensor measurement

position to the marking position.

Target surface of object is inclined.

Make adjustment so that bottom surface of laser

marker head and target surface of object are

parallel with each other.

For LP-M / LP-Z series:

Setting of Uniform Spot Mode is not

appropriate.

Set the Uniform Spot mode within the required

range. If the setting of Uniform Spot mode is

changed, adjust the laser power as the density of

marking may change.

There are variations in properties of

objects.

Object thickness

• Distance to object

• Object surface condition (including

roughness, gloss level, etc.)

• Object material (including chemical

composition ratio)

Adjust marking conditions according to variations

found.

Object feeder is not stable.

Adjust object feeder so that position of objects

become stable.

Performance of laser oscillator

deteriorates due to aging.

• Increase laser power setting.

• Decrease scan speed.

If initial marking quality cannot be reached even

if laser power is set to the upper limit, laser

oscillator must be replaced. Contact our sales

office.

The marking density

of the filling lines in the

drawings or characters is

uneven.

For LP-M / LP-Z series:

The drawing speed of the filling lines is

too fast and the Z-axis control module

cannot follow up the height change.

• Decrease the scan speed.

• Change the marking order or the line filling

directions.

ME-LPS-SSM-8

Summary of Contents for LP-S Series

Page 15: ...15 MEMO ME LPS SSM 8 ...

Page 26: ...26 Chapter 1 Specification ME LPS SSM 8 ...

Page 41: ...41 Chapter 2 Preparation ME LPS SSM 8 ...

Page 78: ...Chapter 3 Connection for External Control ME LPS SSM 8 ...

Page 126: ...Chapter 4 Maintenance ME LPS SSM 8 ...

Page 148: ...Troubleshooting ME LPS SSM 8 ...

Page 169: ...Index ME LPS SSM 8 ...

Page 172: ...172 MEMO No 9000 0066 16V ME LPS SSM 8 ...

Page 173: ...No 9000 0066 16V ...