– A-40 –

Panasonic Corporation Electromechanical Control Business Division

industrial.panasonic.com/ac/e/

©

Panasonic Corporation 2018

AQCTB02E 201806-E

– A-41 –

Panasonic Corporation Electromechanical Control Business Division

industrial.panasonic.com/ac/e/

©

Panasonic Corporation 2018

AQCTB02E 201806-E

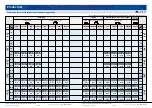

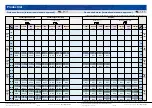

Wiring to motor

Handling instructions

Connecting to the terminal block with seal connector

Tightening torque of the screw used for the terminal box is shown in the table below.

<Precautions>

Round ground terminal and grounding leadwire, and grounding screw, spring washer and flat washer on the ground

return circuit should be prepared by the customer. Earth grounding leadwire should be of size ø1.6 mm (2 mm

2

) or

more.

• Wiring work should be performed by qualified electrician.

• Turn off power and remain off until the wiring is completed.

Grounding (earth ground)

• Positively connect the equipment to the ground.

• Use only the grounding screw provided on the product. Tighten the screw with a toque of 1.2 N·m to 1.5 N·m

(recommended).

• For grounding a motor with seal connector, connect the connector internal ground terminal to the earth.

• Use screw, spring washer and flat washer made of stainless steel or copper alloy in the grounding circuit.

• Use round terminal as grounding terminal. Do not use U-shaped terminal.

Leadwire

Don't forcibly bend, pull or pinch motor leadwires.

Connection

• Connections or joints of motor leadwires, power cable and capacitor should be made using soldering, connector or

crimping terminal, whichever suitable, and should be covered with appropriate insulating material.

• Clamp the motor leadwires on the equipment at stable area so that the leadwires are kept stress free.

Earth terminal screw

Leadwires (Loosely bundle leadwires.)

Earth terminal screw (M4)*

* For grounding a motor with seal connector,

connect the connector internal ground terminal to the earth.

Clamping screw

Screw for cap

Motor

Terminal block

Terminal block cover mounting screw

Terminal block

Place of use

Screw for cap

Terminal block cover mounting screw

Clamping screw

Earth terminal screw

Tightening torque (N·

m

)

3.75 to 4.0

0.78 to 0.98

0.39 to 0.49

1.2 to 1.5

AWG

AWG24

AWG22

AWG20

AWG18

AWG16

AWG14

Cross sectional

area (mm

2

)

0.205

0.326

0.518

0.823

1.31

2.08

JIS

0.2 sq

0.3 sq

0.5 sq

0.75 sq

1.25 sq

2 sq

The applicable wires to the terminal block are as follows.

• Earth grounding leadwire should be of size ø1.6 mm (2 mm

2

) or more.

• Don't squeeze the insulation of the lead wire with the clamp.

• The lead wire should not have fraying conductors.

• Don't solder conductor of the lead wire.

• Clamp the motor leadwires on the equipment at stable area so that the leadwires are kept stress free.

Applicable cabtire cable outer diameter

Stranded wire

Single wire

Earth wire

stripping length

ø8 mm to ø12 mm

AWG14 to AWG20

AWG14 to AWG20

AWG14 or more

7 mm to 7.5 mm

stripping length

7 mm to 7.5 mm

U1

U2

Z2

AWG-JIS Comparison table

Core wire

diameter