– A-46 –

Panasonic Corporation Electromechanical Control Business Division

industrial.panasonic.com/ac/e/

©

Panasonic Corporation 2018

AQCTB02E 201806-E

– A-47 –

Panasonic Corporation Electromechanical Control Business Division

industrial.panasonic.com/ac/e/

©

Panasonic Corporation 2018

AQCTB02E 201806-E

Operating instruction

Inspection and maintenance / Operating conditions / Installation requirements

Handling instructions

Inspection and maintenance

Periodically perform check and maintenance to assure safe and reliable operation.

• Practical considerations for maintenance

• To secure safety during maintenance operation, turning off/on of power supply must be done by the personnel

who is responsible for the current maintenance work.

• Do not touch the motor while it is still running or immediately after it stops. (Motor is hot.)

• Before starting the megger testing of the motor (to measure the insulation resistance), completely disconnect

it from associated devices and components.

Otherwise, the megger tester will damage the devices under test.

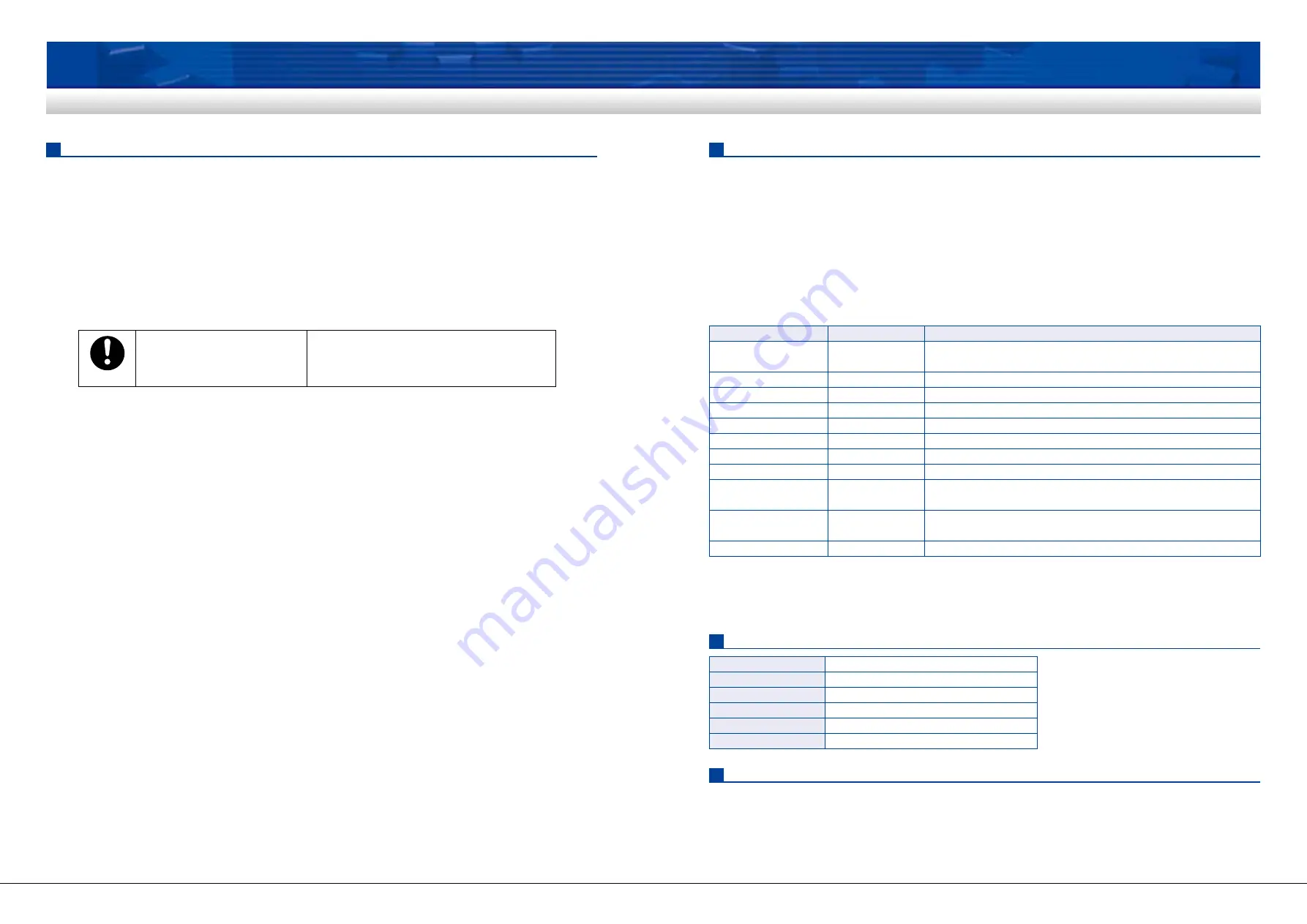

• Daily check

• Perform the daily check to prevent potential problems.

• Perform appropriate corrections upon finding any failure or defective.

• Periodic check (once/1 to 2 month)

• Motor: dust accumulation

• Casing: deformation or corrosion

• Insulation resistance: 1 MΩ or more (across frame and leads)

Operating conditions

Ambient temperature

Ambient humidity

Altitude

Vibration

Operating voltage

Operating voltage

–10 ˚C to + 40 ˚C

85 %RH or less

1000 m or lower

4.9 m/s

2

or less

Nameplate rating ±10 %

*

50 Hz or 60 Hz as specified on the nameplate

*

±10 % is not a guaranteed value for continuous

running condition.

Installation requirements

Install the geared motor at the optimal location as described below for prolonged service life.

(1) Indoor free from rain and direct sunlight

(2) Free from vibration 4.9 m/s

2

or more; shock, dust, iron powder or oil mist; splash of water, oil and grinding

fluid; and away from flammable materials, corrosive gas (H

2

S, SO

2

, NO

2

, Cl

2

, etc.) or flammable gas.

(3) Well ventilated dry and clean location containing negligible amount of oil or dust, and away from heat source i.e. oven.

(4) Location that allows easier access for checking and cleaning of the unit.

(5) Don't use the motor in a closed environment where the motor temperature increases, shortening the life.

Check item

Change in voltage

Load curren

Ambient temperature

Temperature rise

Noise

Vibration

Deposition of powder dust

Oil leakage

Insulation resistance

Grease leakage

Foundation bolt

Checking method

Voltmeter

Ammeter

Thermometer

Thermometer

Auditory perception

Vibrometer/feeling

Visual

Visual

Insulating-resistance

tester

Visual

Torque wrench

Description

Rated voltage ±2 % to 3 %. Although the specification assures normal operation

within ±10 % deviation, the motor performance and life are not secured.

As indicated on the nameplate

–10 ˚C to +40 ˚C

90˚C or below on frame surface (ambient temperature 40 ˚C)

No increase in abnormal sound or noise level

No abnormal vibration

Flow of cooling air is not disturbed by dust and powder

No oil or grease from joint to gear head or from output shaft

Connect the 500 V megger across motor lead and earth terminal.

The reading should be 50 MΩ or more.

Check exterior and peripheral of motor and gear head for coat of grease or oil.

If the leakage will affect the application, use cover as necessary for protection.

Check bolts for loosening and retighten as necessary.

Operating instruction

• Before running the motor

Check the following points:

• Correct wiring to the power source?

• Secure grounding to earth?

• Appropriate fuse and circuit breaker?

• No loose connection to the machine? No loose tightening bolts?

• No oil or grease leakage nor blot?

• Trial running

Make a trial run:

(1) Without a load, turn on the motor and gear head to verify the rotational direction and speed, and check for

abnormal state, i.e. vibration, noise, etc. Install the motor and gear head on the machine.

(2) Turn on power and verify that the motor runs smoothly and the bearing and gear head produce no

abnormal sounds.

• While motor is running

Check the load:

• Measure the current flow rate and adjust the load so that the current value is well below the rating described

on the nameplate.

• When the reduction ratio of the gear head is 1/50 or more, the torque will exceed the permissible shaft

torque even if the measured current value is lower than nameplate rating. If this is the case, decrease the

load.

Check the temperature rise of the motor:

• Temperature rise will saturate by 3 hours after starting the motor. For the reversible motor and single-phase

induction motor with electromagnetic brake, observe the time rating of 30 minutes.

• Keep the frame temperature 90 ˚C or below when the ambient temperature is 40 ˚C.

• At power failure:

Immediately turn off main power switch.

• Unexpected accident may occur when the power recovers while the switch is in on position; or the motor

may not start if the load is too heavy and the winding may burn.

• While the motor is running:

• Do not touch the motor since it gets very hot. (Or it may result in burn injury.)

• Turn off the motor as the system shows unexpected behavior. (Consult the local agent as necessary.)

• Other precautions:

Check the starting voltage:

With the geared motor installed on the machine, check the starting voltage of the motor using a variable

transformer and voltmeter. The voltage should be lower than the value shown below.

(1) Reversible motor: 70 % of the rated voltage

(2) Induction motor: 80 % of the rated voltage

• The machine may not start if the voltage fluctuates. The machine may not start because of change in the

static friction torque due to the aging or temperature, or fluctuation of the motor.

Do

Check rotating direction

Unexpected operation or movement will

cause malfunction or personal injury.