7

2.6.

Power Nozzle Light Bulb

2.6.1.

Bulb Removal

1. Remove Power Nozzle cover (see Nozzle Cover -

Removal).

2. Remove bulb by pulling straight out.

2.6.2.

Bulb Reinstallation

1. To replace bulb cafeully push fully into slot. Use bulbs

only rated 13V AC (9W).

2. Reinstall Power Nozzle cover (see Nozzle Cover -

Replacement).

.

2.7.

Power Nozzle Motor

2.7.1.

Specifications

1. 120V., 60Hz.

2. Amps 2.0/2.7 (max.) at 18,000/14,550 R.P.M.

3. Watts 225/298 (max.) at 18,000/14,550 R.P.M.

4. Torque 55/100 Nm at 18,000/14,550 R.P.M.

2.7.2.

Removal

1. Remove nozzle cover and agitator assembly (See Nozzle

Cover and Belt & Agitator).

2. Remove two (2) motor bracket screws. Lift out bracket

and motor.

NOTE:

Observe routing of motor wires and all other wiring

before removing motor.

3. Remove two (2) motor bracket screws. Lift out bracket

and motor.

4. Remove the overload protector wire terminals. Check

continuity by depressing the button completely. When the

button is released there should be continuity between the

two poles when checked. If all components and items in

the troubleshooting guide have been checked and the

overload protector continues to trip, it should be replaced.

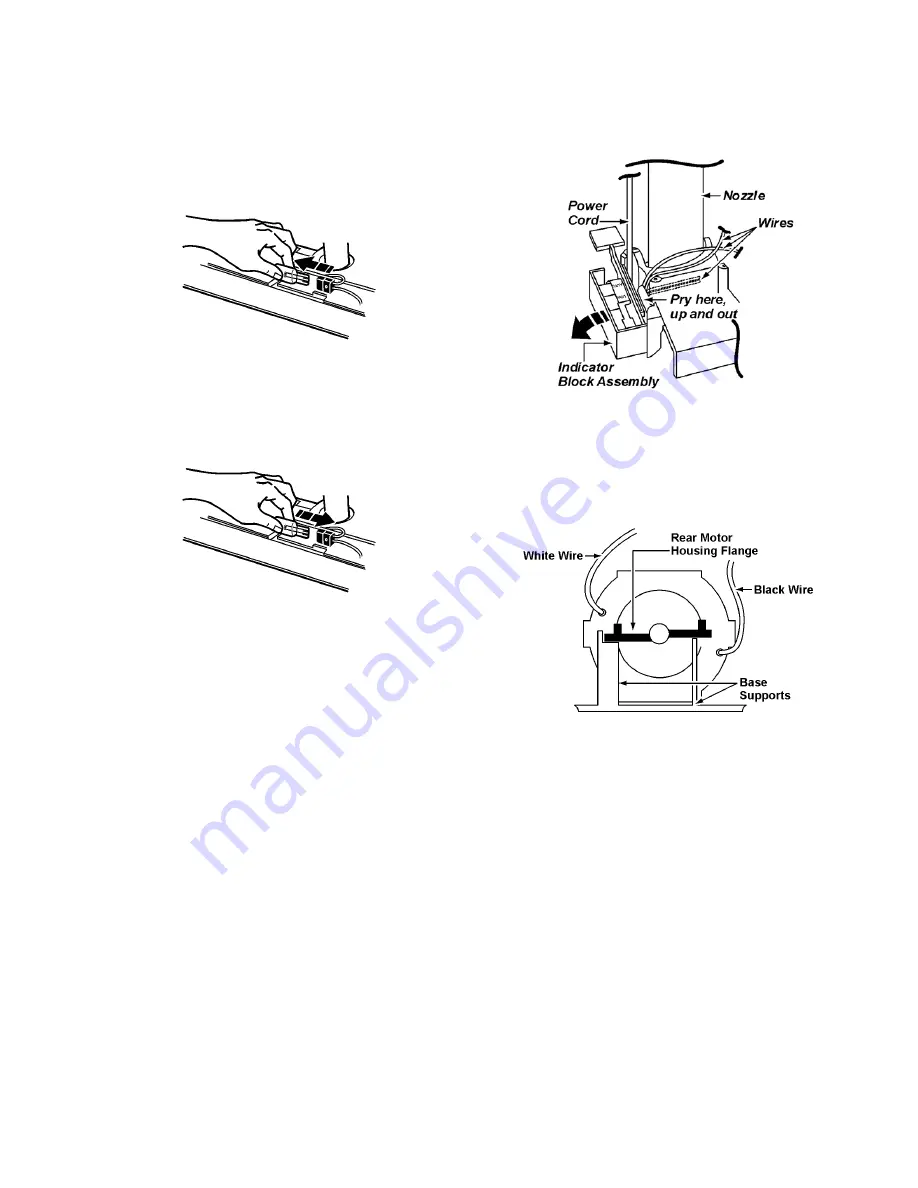

5. Insert a flat screwdriver blade between the indicator block

assembly and the plastic retainer for the four (4) wires.

Pry up and out to free the indicator block assembly from

the retaining tabs.

2.7.3.

Reinstallation

1. Install new motor.

CAUTION:

Do not pinch wires.

2. Install motor bracket and secure with two (2) screws.

3. Reroute all wiring per original layout utilizing wire

retainers provided, and proper placement of wires to

prevent pinching of wires and interference when

reinstalling the indicator block assembly. Connect wires

and apply wire nuts, (reference WIRIING DIAGRAM and

WIRE MANAGEMENT).