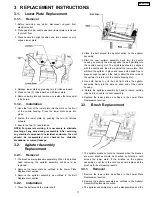

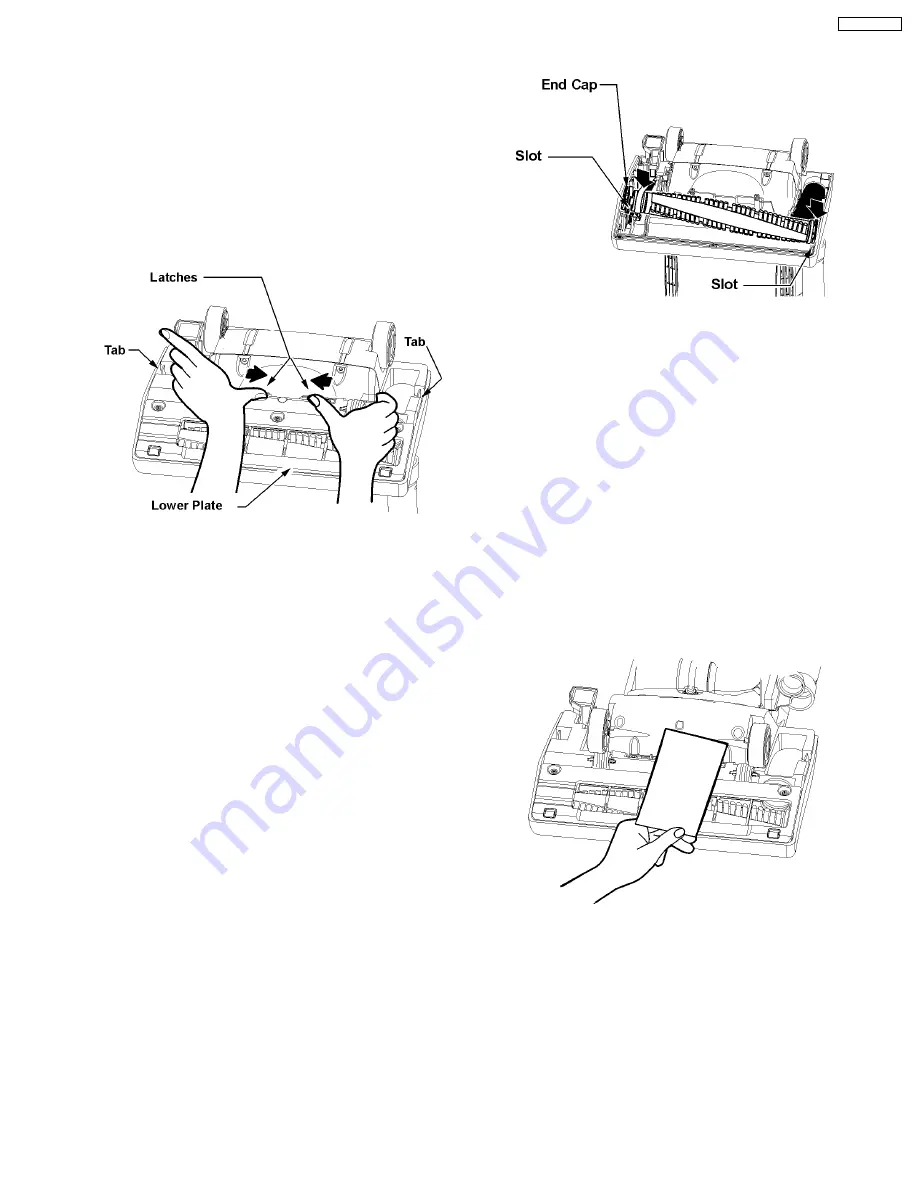

3.1. Lower Plate Replacement

3.1.1. Removal

1. Before servicing any parts, disconnect vacuum from

electrical outlet.

2. Place paper under nozzle whenever lower plate is removed

to protect floor.

3. Place handle in upright position and turn vacuum over to

expose lower plate.

4. Release lower plate by pressing two (2) latches inward.

5. Press on two (2) tabs inward and lift lower plate.

6. Remove lower plate and remove any residue that may exist

in belt area.

3.1.2. Installation

1. Hook the front of the lower plate into the slots on the front

of the nozzle housing. Press the lower plate down into

place.

2. Fasten the lower plate by pushing the two (2) latches

outward.

3. Ensure the two (2) tabs latched.

NOTE: For general servicing, it is necessary to eliminate

pinching of any wire during reassembly. After servicing

any electrical component or electrical enclosure, the unit

should be reassembled and checked for dielectric

breakdown or current leakage.

3.2. Agitator Assembly

Replacement

3.2.1. Removal

1. The brushes are replaceable separately. When the brushes

need replacing, the agitator assembly will have to be

removed.

2. Remove the lower plate as outlined in the Lower Plate

Replacement section.

3. Remove the agitator assembly as outlined in the Belt

Replacement section. .

3.2.2. Installation

1. Place the belt around the motor shaft.

2. Place the belt around the agitator pulley on the agitator

assembly.

3. Start the new agitator assembly back into the nozzle

housing by placing the side opposite the belt partially into

the nozzle housing slot. The small tabs should be aligned

with the nozzle and the other against the lower plate. This

will hold the agitator in place and leave both hands free to

place enough tension on the belt to allow the other side of

the agitator to return into the nozzle housing slot.

4. Use both hands to pull the belt tight, slide the agitator

assembly firmly into the slots on each end of the nozzle

housing.

5. Rotate the agitator assembly by hand to insure nothing

rubs and to check for correct assembly.

6. Replace the lower plate as outlined in the Lower Plate

Replacement section.

3.3. Brush Replacement

1. The agitator brushes should be replaced when the brushes

are worn. Brushes should be checked by holding a card

across the lower plate. If the bristles on the agitator

assembly do not touch the card you should replace all the

brushes for best cleaning results.

3.3.1. Removal

1. Remove the lower plate as outlined in the Lower Plate

Replacement section.

2. Remove the agitator assembly as outlined in the Agitator

Assembly Replacement section.

3. The agitator assembly may now be disassembled and the

3 REPLACEMENT INSTRUCTIONS

11

MC-GG773-00