Summary of Contents for MDF-DU702VH

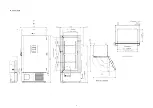

Page 8: ...Dimension MDF DU502VH 5 ...

Page 9: ...MDF DU702VH 6 ...

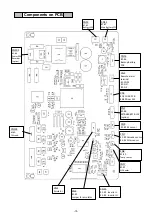

Page 17: ...Wiring Diagram 14 ...

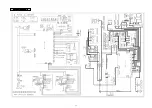

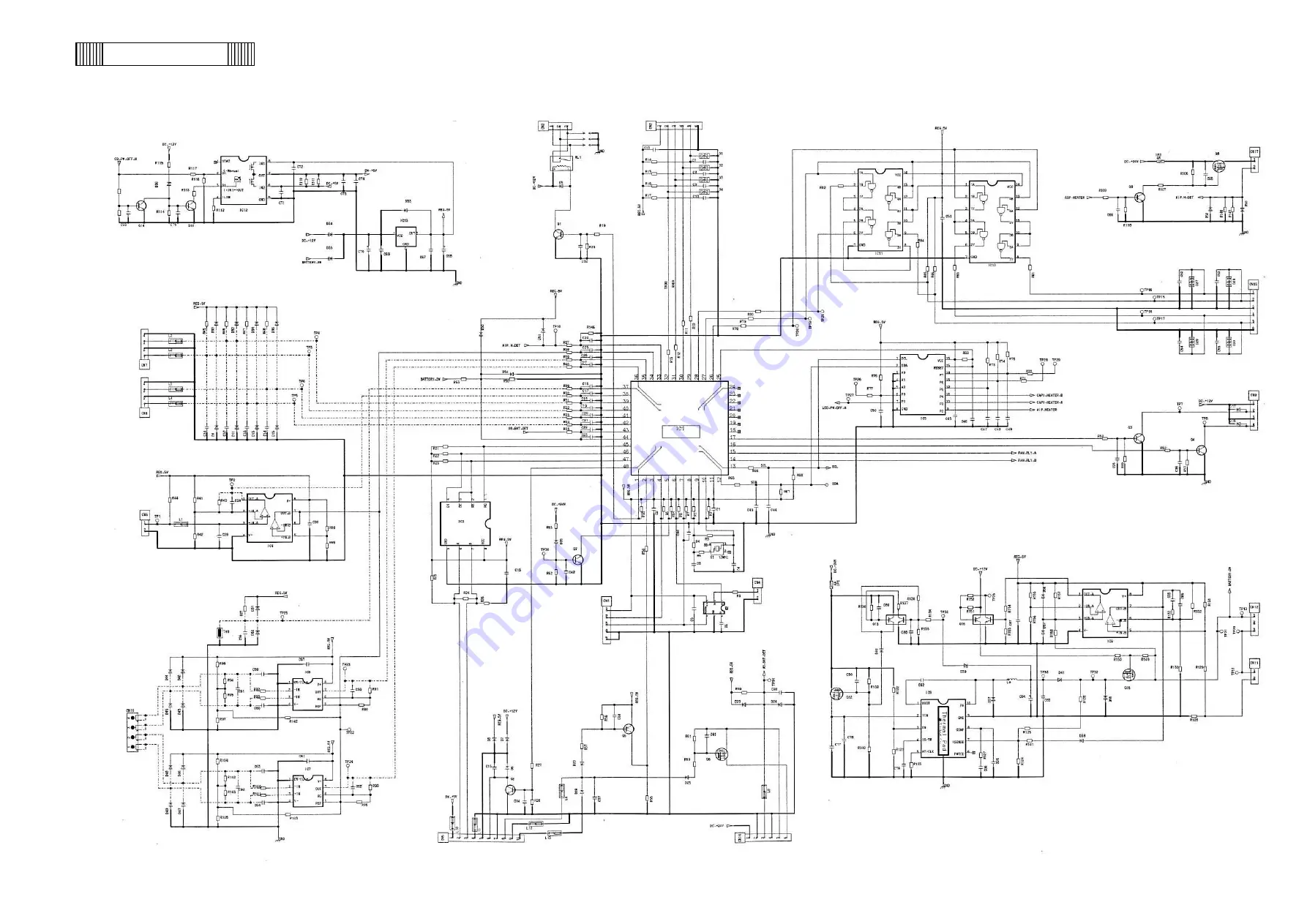

Page 18: ...main Circuit Diagram 15 ...

Page 19: ...power 16 ...

Page 20: ...USB 17 ...

Page 73: ...WIRING YG Y Y GR B G W W W Y G R BL Y W R R BL R OR B BL R OR B Y W Y G Y G R BL 70 ...