28

DISPOSAL OF BATTERY

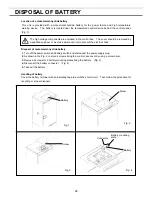

Location of a nickel-metal-hydride battery

This unit is provided with a nickel-metal hydride battery for the power failure and high temperature

warning device. The battery is located near the temperature control device behind the control panel.

(Fig. 1)

The high voltage components are enclosed in the control box. The cover should be removed by

a qualified engineer or a service personnel only to prevent the electric shock..

Disposal of nickel-metal-hydride battery

1.

Turn off the power switch and battery switch and disconnect the power supply plug.

2.

As shown in the Fig. 2, remove 4 screws fixing the control case cover by using a screw driver.

3.

Remove 2 screws for 2 battery mounting plates fixing the battery. (Fig. 3)

4.

Disconnect the battery connector. (Fig. 4)

5.

Take out the battery.

Handling of battery

Cover the battery terminal with an insulating tape to avoid the short circuit. Then follow the procedure for

recycling or proper disposal.

Fig. 1

Battery

Fig. 2

Screw

Screw

Fig. 3

Fig. 4

Connector

Battery mounting

plate

Battery