30

SPECIFICATIONS

Product name

Biomedical Freezer

MDF-U731

External dimensions

W770 mm x D830 mm x H1955 mm

Internal dimensions

W650 mm x D700 mm x H1370 mm

Effective capacity

623 L

Exterior

Painted steel

Interior

Painted steel

Door Painted

steel

Lock 1

Insulation

Rigid polyurethane foamed-in place

Shelf

Polyethylene coated wire

4 pieces

Size: W626 mm x D620 mm Max. load: 50

kg

/shelf

Access port

Diameter 30 mm, 1 port on left side

1 port on the top of unit

Cooling method

Forced air circulation

Compressor

Hermetic type, 400 W

Evaporator

Fine and tube

Condenser

Skin condenser type

Refrigerant

R-404A

Defrosting Heater

defrosting

Temperature controller

Electronics controller

Temperature display

Digital display (between -40

o

C and +0

o

C)

Temperature sensor

Thermister sensor

Alarm & safety

High temp. alarm, Low temp. alarm, Power failure alarm, Door alarm,

Compressor temperature alarm, Thermal sensor abnormality

Memory backup

Nonvolatile memory

Weight

155

kg

Battery

Nickel-metal-hydride battery, DC 6 V, 1500 mAh, Auto-recharge (DRTB315005)

Accessories

1 set of key, 1 Inspection label, 4 of plastic screws,

2 large & 2 small nylon clips (for temperature recorder)

Caster 4

Leveling foot

2

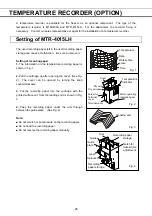

Optional component

Temperature recorder (MTR-G85A)+Recorder fixing (MPR-S7),

Temperature recorder (MTR- Recorder fixing (MPR-S30)

• Design or specifications will be subject to change without notice.

• Refer to the updated catalog when ordering an optional component.