7

LABELS ON THE UNIT

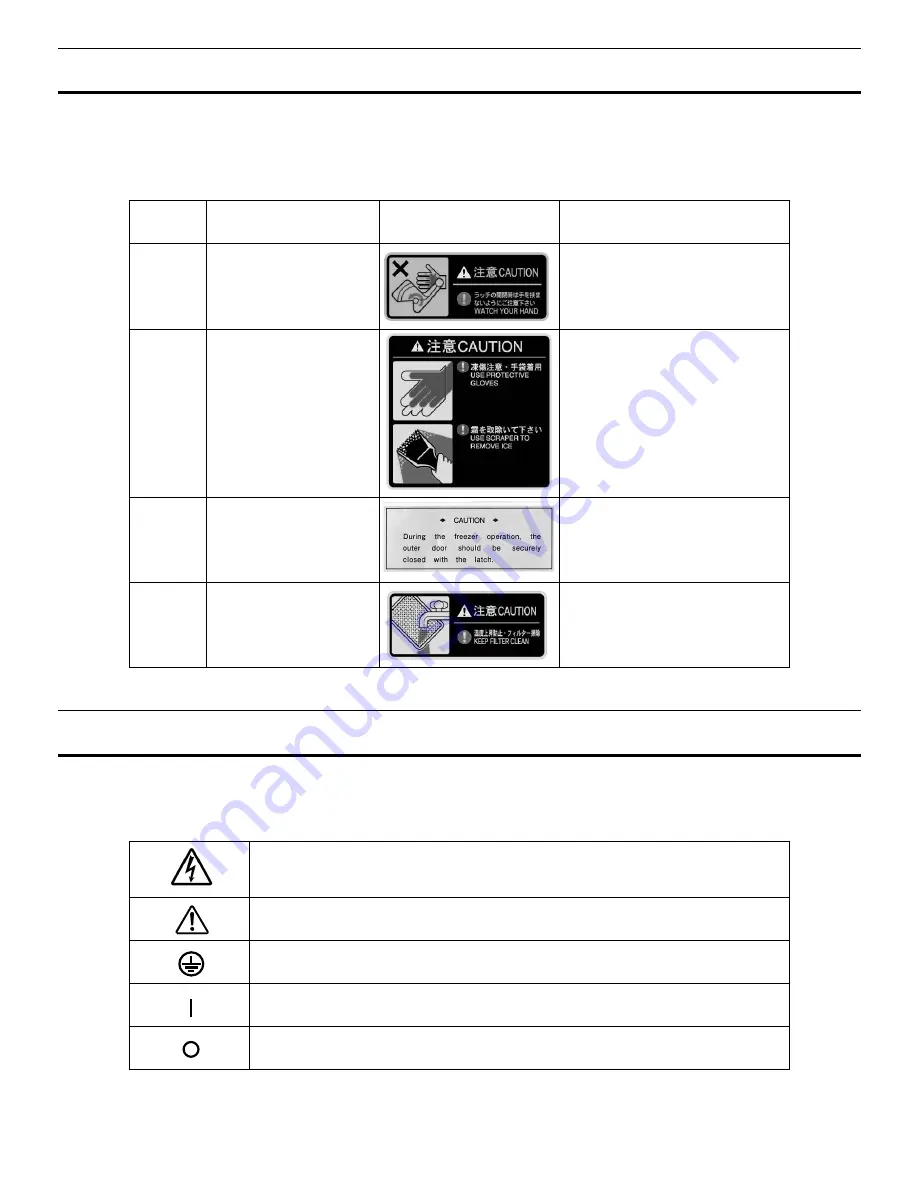

Warning safety labels applied to the ultra-low temperature freezer

Users are advised to avoid accidents by carefully reading the warnings and cautions contained on warning

labels at key locations on the interior and exterior of the ultra-low temperature freezer.

Possible

Danger

Warning/Caution Type

Location of Danger

Warning/Caution Label

Description of Danger

Personal

injury

Hazardous Latch

Latch

Dangerous to put a hand.

Personal

injury

Frostbite and frost

Interior

Frostbite and frost caution label.

Sample

damage

Chamber temperature

Interior

Forgets to close a door and latch.

Sample

damage

Chamber temperature

Interior

Rise in temperature is prevented.

SYMBOLS ON THE UNIT

The symbols are attached to the ultra-low temperature freezer. The following table describes the

symbols.

This symbol is attached to covers that access high-voltage electrical components to

prevent electric shock. Only a qualified engineer or service personnel should be

allowed to open these covers.

This symbol indicates that caution is required. Refer to product documentation for

details.

This symbol indicates an earth.

This symbol means “ON” for a power switch.

This symbol means “OFF” for a power switch.