No. SX-DSV02829 -

76-

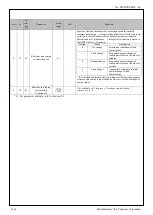

Class

No.

At-

trib-

ute *1)

Title

Range

Unit

Function

6

32

B

Real time auto

tuning custom

setup

(Continued)

-32768–32767

—

Bit

Content

Description

7

Stiffness

Setup

*5

Enable/disable the basic gain setup to

be made according to Pr0.03

(Real-time auto-tuning machine

stiffness setup).

Setup value=0: Disable

Setup value=1: Enable

8

Fixed

parameter

setup

*5

Enable/disable the change of

parameter that is normally set at a

fixed value.

Setup value=0: Use current setup

Setup value=1: Set to a fixed value.

10–9

Gain

switching

setup

*5

Select the gain switching related

parameter to be used when the real

time auto tuning is enabled.

Setup value=0: Use current setup

Setup value=1: Disable gain switching.

Setup value=2: Enable gain switching.

*3 If the inertia ratio update is enabled, set bit 1–0 to 1(enable). If

neither is effective, the mass ratio is not updated.

*4 If the torque compensation is abled (setup value=2-5), set bit

3–2(Inertia ratio update) to 1(enable). If neither is effective, the

inertia ratio is not updated. The torque compensation alone cannot be

updated.

*5 Set bit3–2(Inertia ratio update) to 1(enable) when this setting is set

excluding 0. At this time, you can be set whether to inertia ratio

update to be effective with bit 1-0(Load characteristics estimation).

Caution) This parameter should be setup bit by bit. Because the

operation is not guaranteed when the setting is wrong, use of the setup

support software is recommended for parameter editing.

Caution) Do not change while the motor is operating. With this

parameter is updated, when the motor stopped after the result of load

characteristic measurement secured.

<Setup procedure of bitwise parameter>

When setting parameter to a value other than 0, calculate the setup

value of Pr 6.32 in the following procedure.

1) Identify the LSB of the setup.

Example: LSB of the torque compensation function is 4.

2) Multiply the setup value by power of 2 (LSB).

Example: To set the torq torque ue compensation function to friction

compensation (middle):

2

4

×

4 = 64.

3) Perform steps 1) and 2) for every setup, sum up the values which

are to be Pr 6.32 setup value.

Example: Load characteristics measurement = enable, inertia ratio

update = enable, torque compensation = friction compensation

(middle), stiffness setup = enable, fixed parameter = set to a fixed

value, gain switching setup = enable, then,

2

0

×

1+2

2

×

1+2

4

×

4+2

7

×

1+2

8

×

1+2

9

×

2 = 1477

*1) For parameter attribute, refer to Section 9-1.

R1.00

Motor Business Unit, Panasonic Corporation