-

27

-

-

26

-

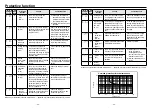

Test run

Description of

operation

1.Turn on power

2.Set the action

Pr4E

Setting of

(

teaching speed

)

3.Return to

monitor mode.

Operation panel

Switch

LED display

Press

Press and choose parameter 4E

(teaching speed).

(Initial setting: 50)

Press

Press and change the teaching speed to 300.

Press

Press

4.Teaching

operation

5.Exit

Press

Press for 4 seconds

When is pressed in this condition, the

motor rotates in + direction* and 5-digit

LED indicates position coordinates.

When is pressed after the motor has

stopped, the motor rotates in one direction.

When is released, the motor stops.

(LED display "5000" is an example, which

shows the present position of the motor.)

When exiting the mode without setting

data, press switch to return to

monitor mode.

When is released, the motor stops.

(LED display ". . 3.5.5." indicates that

the present position is –355.)

Flashing

Flashing

Flashing

Flashing

Flashing

Flashing

Flashing

Flashing

All light up.

All light up.

All light up.

All light up.

All light up.

All light up.

Flashing

Flashing

Flashing

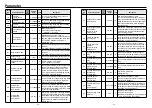

Description of

operation

Operation panel

Switch

LED display

Inspection before Test run

1) Make sure that all wiring is correct.

2) Make sure that input power supply conforms to rating.

Test run

Procedure for test run using the Digital key pad is as follows:

Shown here is the case of running at 300r/min in direction CW or CCW by use of teaching

function.

First execute the following work for safe operation.

[1] Ensure that the motor alone can be operated.

[2] Turn on power and follow the steps below for test run.

Checkpoint in Test run

[1] Check whether the motor rotates smoothly. Check for abnormal noise and vibration.

[2] Check whether the motor is accelerated and decelerated smoothly.

[3] Make sure that the direction of motor rotation is correct.

* Rotation dir represents CCW on the motor shaft in default setting. (Can be

changed by Pr23 coordinate system setting.)

Rotation direction of gear head output shaft may sometimes be reversed due to re-

duction gear ratio when gear head is installed.

(See the table of permissible shaft torque on P.29. Rotation direction is described.)