-

9

-

-

8

-

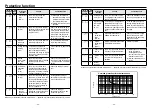

Safety precaution label

is affixed to the product.

Connector for motor cable and

CS signal cable

Ground terminal

Oil seal

Output shaft

Safety precaution label

is affixed to the product.

O-ring (not provided on a round shaft model)

Motor nameplate

Bracket B

Frame

[Front view]

[Side view]

Connector for

motor connection

(MOTOR)

Power LED

(green: when power is ON)

Alarm LED

(red: when Trip is operation )

Connector for

communications

(SER)

Connector for power input

(POWER)

Connector for control signals

(I/O)

Attachment hole

Grounding terminal screw

Name of part

Brushless motor

Brushless amplifier

Name of part

Installation

Install the brushless motor and brushless amplifier properly for preventing failure

and accident.

Transport

• Use caution enough in transporting the unit to prevent injury by drop or fall, and avoid

damage to the equipment.

Storage

• Keep the unit indoors in a clean and dry place free from vibration with little change of

temperature.

• In keeping a gear head alone, direct the output shaft down.

(Otherwise, grease leaking is possible.)

Location

• Location gives great influence upon the life of brushless motor and brushless amplifier,

therefore choose a place in conformance with the conditions below:

(1) Indoors where the motor is not subjected to rain water and direct sun beam.

(2) Do not use the motor in corrosive atmosphere such as hydrogen sulfide, sulfurous

acid, chlorine, ammonia, sulfur, gas chloride, gas sulfide, acid, alkali, and salt, in the

atmosphere of combustible gas, or in the vicinity of flammables.

(3) Place not exposed to grinding liquid, oil mist, iron powder, and cutting particle.

(4) Well-ventilated place with little moisture, oil, or inundation, and place far from heat

source such as a furnace.

(5) Place easy to check and clean

(6) Place free from vibration

(7) Do not use the unit in an enclosed environment. Enclosing may raise the temperature

of motor (amplifier), and shorten their life.

Caution in installing gear head

Install a device that will ensure safety operation of the system even if the following

failures should occur on the life end of gear head: idling by damaged teeth, locking

by bite, grease leakage, and the like.

•

As for application such as on a lifter or the like device, install a device for preventing drop

by damaged teeth.

•

As for application such as opening and closing of door, install a release device against

locking by gear biting.

•

As for food or textile equipment, install an oil pan for measures against grease leakage.

•

Do not install an encoder, sensor, contact, etc., in the proximity of gear head. Or

otherwise, protect such devices against grease leakage.

• In order to prevent unexpected accident, be sure to perform daily check.