-

E15

-

-

E14

-

English

Conformance to EC directive and UL standard/ Specifications

EC Directives

The EC directives apply to all such electronic products as those having specific functions

and directly sold to general consumers in EU countries. These products are required to

meet the EU unified standards and to be furnished with CE marking.

Our brushless motor and amplifier meet the EC Directives for Low Voltage Equipment so

that the machine or equipment comprising our brushless motor and amplifier can meet

relevant EC Directives.

EMC Directives

Our brushless motor can meet EMC Directives and related standards. However, to meet

these requirements, the systems must be limited with respect to configuration and other

aspects, e.g. the installation and some special wiring conditions must be met. This means

that in some cases machines and equipment comprising our brushless systems may

not satisfy the requirements for wiring and grounding conditions specified by the EMC

Directives. Therefore, conformance to the EMC Directives (especially the requirements for

emission noise and noise terminal voltage) should be examined based on the final products

that include our system.

Applicable standard

Applicable standard

UL

UL1004

Standard for electric motor

CSA

(c-UL)

C22.2 No.100

Standard for electric motor

CE

EN60034-1

Standard for rotary electric machine (low voltage directive)

EN60034-5

Standard for rotary electric machine (low voltage directive)

CCC

GB12350

Safety standard for low-power electric motor

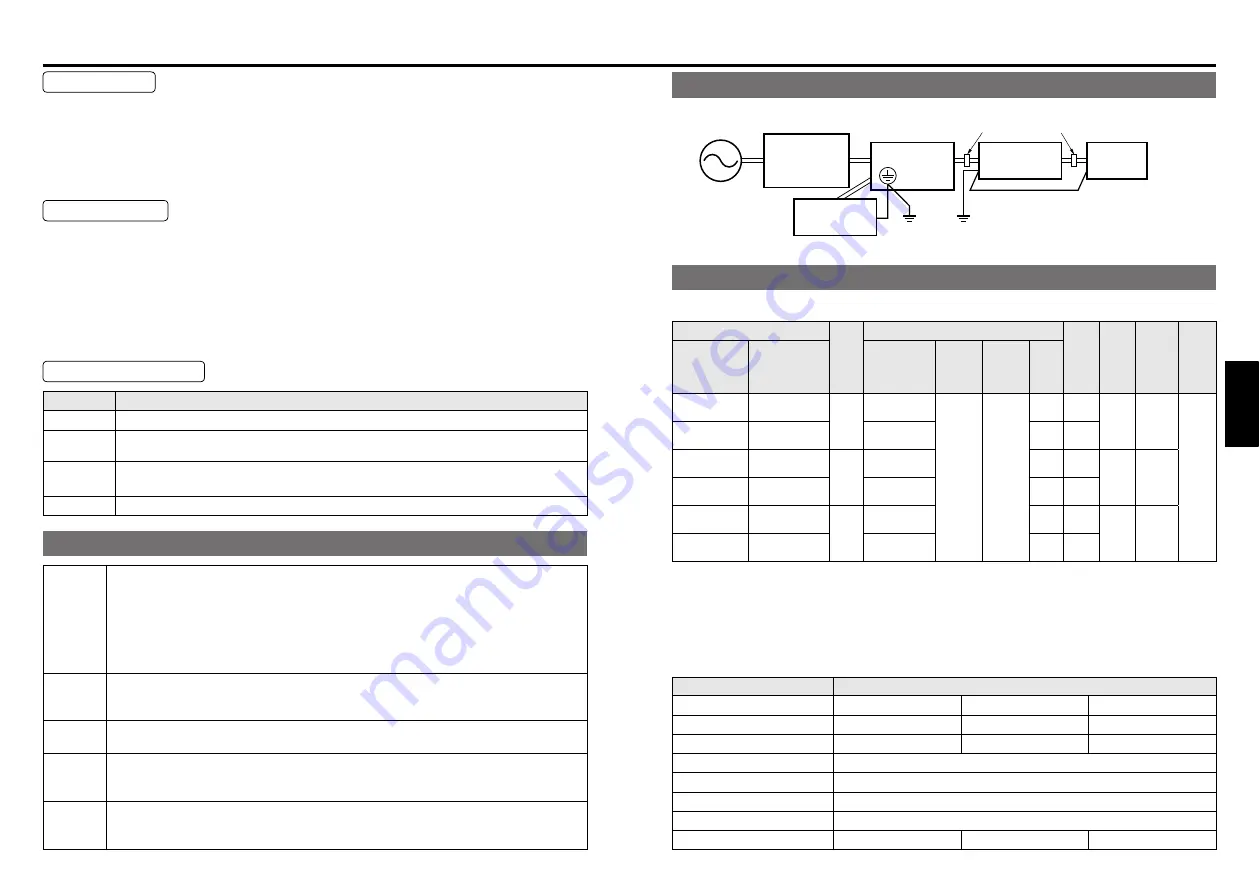

Configuration of peripheral equipment

Power

supply

・

100 V system: Single phase 100 V to 120 V ± 10%, 50/60 Hz

200 V system: Single phase 200 V to 240 V ± 10%, 50/60 Hz

・

Use the equipment under the environment of overvoltage category II specified by

IEC60664-1.

In order to obtain overvoltage category III, insert a transformer conforming to EN

standard or IEC standard to the input of brushless amplifier.

・

Use an electric wire size suitable to EN60204-1.

Circuit

breaker

Fuse

Be sure to connect a specified no-fuse breaker certified by IEC standard or UL, or

a fuse certified by UL between power supply and noise filter. Meeting this condition

allows conformance with UL508C (file No. E164620) and UL1004 (file No. E166557).

Noise

filter

When installing one noise filter at the power supply for more than one brushless motor

used, contact the manufacturer of noise filter.

Surge

absorber

Install a surge absorber on the primary side of noise filter. However, in performing

the voltage resistance test of machine and equipment, be sure to remove the surge

absorber; otherwise, the surge absorber may be ruptured.

Grounding

Be sure to connect the grounding Terminal of brushless amplifier and protective

grounding wire (PE) of system for preventing electric shock. Do not tighten the

grounding wires together but connect them individually.

Conformance to EC directive and UL standard

Wiring of peripheral equipment

Specifications

• General specification

Model name

Rated

output

(W)

Power input

Motor

Rated

Current

(A)

Rated

torque

(N

・

m)

Starting

torque

(N

・

m)

Rated

rotation

speed

(r/min)

Brushless

*

motor

Brushless

*

amplifier

Voltage

(V)

Tolerance

(%)

Frequency

(Hz)

Rated

input

current

(A)

MBMU5AZA

*

MBEG5A1BC

*

50

Single phase

100 to 120

±10

50/60

1.5

0.53

0.16

0.24

3000

MBMU5AZA

*

MBEG5A5BC

*

Single/3-phase

200 to 240

0.7

0.53

MBMU9A1A

*

MBEG9A1BC

*

90

Single phase

100 to 120

2.2

1.0

0.29

0.43

MBMU9A2A

*

MBEG9A5BC

*

Single/3-phase

200 to 240

1.1

0.5

MBMU1E1A

*

MBEG1E1BC

*

130

Single phase

100 to 120

2.8

1.3

0.41

0.62

MBMU1E2A

*

MBEG1E5BC

*

Single/3-phase

200 to 240

1.5

0.72

*

The “

*

” in the motor designation is replaced with the symbol indicating the shaft specification.

*

The “

*

” in the amplifier designation is replaced with the character V indicating GV series or

P indicating GP series.

• Never use a GP series amplifier in combination with a GV series motor.

A wrong combination will cause malfunction.

• Common specification

Item

Specifications

Brushless motor

MBMU5AZA

*

MBMU9A

*

A

*

MBMU1E

*

A

*

Brushless amplifier

MBEG5A

*

BC

*

MBEG9A

*

BC

*

MBEG1E

*

BC

*

Rated output (W)

50

90

130

Rated speed

3000 r/min

Speed control range

30 to 4000 r/min (Speed ratio 1:133)

Motor heat resistance class

130(B) (UL certified 105 (A))

Time rating

Continuous

Motor mass (kg)

(

0.7

)

(

1.0

)

(

1.2

)

Molded Case

Circuit Breaker

(MCCB)

or Fuse

Brushless

amplifier

Brushless

motor

Surge

absorber

Noise filter

Protection ground

(PE)

ground

Power

supply

Ferrite core (Noise filter for signal line)

option DV0P1460 (*Qty.

:

4 ) (part No.: ZCAT3035-1330/TDK Corp.)

* The ferrite core should insert one

or more pieces in an electric wire,

respectively.