50

1

2

3

4

4

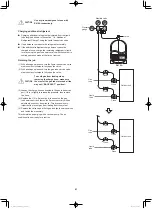

Auto Address Setting* from the Remote Controller (CZ-RTC4)

* Auto address setting in Cooling mode cannot be done from the remote controller.

NOTE

●

Selecting each refrigerant system individually for auto address setting

●

Auto address setting for each system

: Item code “A1”

1

Press the remote controller timer time

button and

button at

the sa

me time.

(Press and hold for 4 seconds or longer.)

2

Next, press either the temperature setting

/

button. (Check

that the item code is “A1”.)

3

Use either the

button to set the system No. to perform auto

address setting.

4

Then press the

button.

(Auto address setting for one refrigerant system begins.) (When auto

address setting for one system is completed, the system returns to

normal stopped status.)

<Approximately 4 – 5 minutes is required.>

(During auto address setting, “

” is displayed on the remote

controller.

This message disappears when auto address setting is completed.)

5

Repeat the same steps to perform auto address setting for each

successive system.

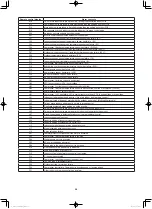

Auto Address Setting from the High-spec Wired Remote Controller (CZ-RTC5A)

4

Select the “O/D unit no.” by pressing the

or

button.

Select one of the “O/D unit no.” for auto address by pressing

the

or

button.

Approximately about 10 minutes are required.

When auto address setting is completed, the units return to

normal stopped status.

START

[ ]

20:30 (THU)

CZ-RTC5A

CZ-RTC4

1

Keep pressing the

,

and

buttons

simultaneously for 4 or more seconds.

The “Maintenance func” screen appears on the LCD display.

2

Press the

or

button to see each menu.

If you wish to see the next screen instantly, press the

or

button.

Select “9. Auto address” on the LCD display and press the

button.

Maintenance func

10. Set elec. consumption

12. Check touch key

Sel.

Page [

] Confirm

20:30 (THU)

11. Set touch key

9. Auto address

3

The “Auto address” screen appears on the LCD display.

Change the “Code no.” to “A1” by pressing the

or

button.

Auto address

Code no.

O/D unit no.

Sel.

Next

20:30 (THU)

1

A1

00_291827_2WAY_Eng.indb 50

2017/7/5 13:41:39