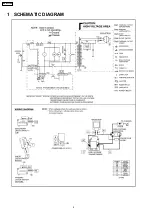

1 SCHEMATIC DIAGRAM

4

2 DESCRIPTION OF OPERATING SEQUENCE

5

2.1.

Variable power cooking control

5

2.2.

Turbo Defrost, Auto Reheat, Auto Cook control

5

3 CAUTIONS TO BE OBSERVED WHEN TROUBLESHOOTING 6

3.1.

Check the grounding

6

3.2.

Warning about the electric charge in the high voltage

capacitor

6

3.3.

When parts must be replaced, unplug the power cord from

the wall outlet.

6

3.4.

When the 8 Amp fuse is blown due to the malfunction of

short switch:

6

3.5.

Avoid inserting nails, wire, etc. through any holes in the

unit during operation.

6

3.6.

Verification after repair

6

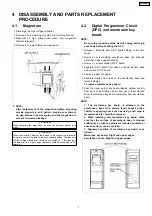

4 DISASSEMBLY AND PARTS REPLACEMENT PROCEDURE 7

4.1.

Magnetron

7

4.2.

Digital Programmer Circuit (DPC) and membrane key

board.

7

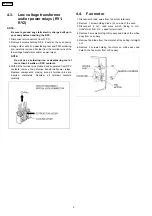

4.3.

Low voltage transformer and/or power relays (RY1, RY2)

8

4.4.

Fan motor

8

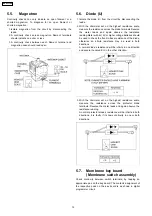

4.5.

Door assembly

9

4.6.

Turntable motor

9

4.7.

Quartz heater

10

5 COMPONENT TEST PROCEDURE

11

5.1.

Primary, Secondary Latch Switch Interlocks

11

5.2.

Short Switch & Monitor

11

5.3.

High voltage transformer

11

5.4.

High voltage capacitor

11

5.5. Magnetron

12

5.6.

Diode (U)

12

5.7.

Membrane key board (Membrane switch assembly)

12

6 MEASUREMENTS AND ADJUSTMENTS

13

6.1.

Adjustment of Primary latch switch, Secondary latch

switch and Short switch.

13

6.2.

Measurement of microwave output

13

7 TROUBLESHOOTING GUIDE

14

7.1.

Trouble related to Digital Programmer Circuit

15

7.2.

How To CHECK THE SEMICONDUCTORS USING AN

OHM METER

16

8 EXPLODED VIEW AND PARTS LIST

17

8.1.

EXPLODED VIEW

17

8.2.

PARTS LIST

18

8.3.

DOOR ASSEMBLY

19

8.4.

WIRING MATERIALS

20

8.5.

PACKING AND ACCESSORIES

21

8.6.

ESCUTCHEON BASE ASSEMBLY

22

9 DIGITAL PROGRAMMER CIRCUIT

23

9.1.

SCHEMATIC DIAGRAM

23

9.2.

PARTS LIST

25

CONTENTS

Page

Page

3

NN-G335WF

Summary of Contents for NN-G335WF

Page 2: ...2 NN G335WF ...

Page 4: ...1 SCHEMATIC DIAGRAM 4 NN G335WF ...

Page 15: ...7 1 Trouble related to Digital Programmer Circuit 15 NN G335WF ...

Page 16: ...7 2 How To CHECK THE SEMICONDUCTORS USING AN OHM METER 16 NN G335WF ...

Page 17: ...8 EXPLODED VIEW AND PARTS LIST 8 1 EXPLODED VIEW 17 NN G335WF ...

Page 23: ...9 DIGITAL PROGRAMMER CIRCUIT 9 1 SCHEMATIC DIAGRAM 23 NN G335WF ...

Page 24: ...24 NN G335WF ...