XI. METHODE TO REPAIRING REFRIGERATING UNIT

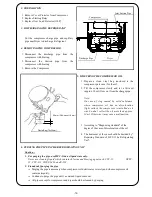

CONDITION I. NOT COLD

Compressor not run

CONDITION II. COLD LESS

CONDITION III. VERY COLD

Both terminal direct

joining

Compressor run

Compressor not run

Compressor run

Check with Ohm Meter

( Tester )

Change Thermostat

OLP broken

Check with M.Tester

Change O L P

Starting PTC broken

Check with M.Tester

Change Starting PTC

Motor winding burn

Check with M.Tester

Change Compressor

Compressor noise but

not run

Power source broken

(Start Voltage not

enough )

Starting P.T.C. broken

Motor winding

disconnect

Starting Motor burn

Check Starting P.T.C.

Voltage under load

Check with

M.Tester

Check with M.Tester

Repair Power Source

Change PTC Starting

Change Compressor

Change Compressor

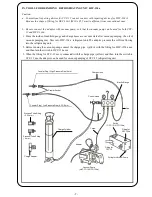

Cooling Unit brooken

Gas leakage

Be found gas residu

Repair gas leakage and

re-charge

Gas nothing

Spray with gas

Compressor run but not

compress

Short time

Operation fault

Thermostat broken

Change Thermostat

Compressor running

Long time

Out side Evaporator

Evaporator closed by

frost to more

Evaporator not close by

frost

Very Cold

Touch Defrost button

Cooling Unit broken

Repair at cooling unit

portion

Joint pipe leakage and

clogged

The door have more

gap

Open the door very

long time

Cold Less

Check Cooling Unit

Repair at cooling unit

portion

Adjust the door

Give the direction to

customer

Censor cappilary

Thermostat have more

gap

Thermostat broken

Thermostat not have

voltage

Assembly censor

cappilary Thermostat

Check with M.Tester

Setting end of Censor at

center hole

Change Thermostat

Repair Thermostat

wiring

Check with M.Tester

CHECK

CAUSE

SUSPECT

ANALYSIS

ACTION

-9-

Summary of Contents for NR-B203G-S7

Page 10: ... 9 ...

Page 22: ...1 Part Structure 1 2 LIST OF SPARES PARTS INDICATED SAFETY PART 52 90 91 19 ...

Page 23: ...PMIRF0806022AI 1 2 Part Structure 2 2 20 ...

Page 26: ... 22 ...