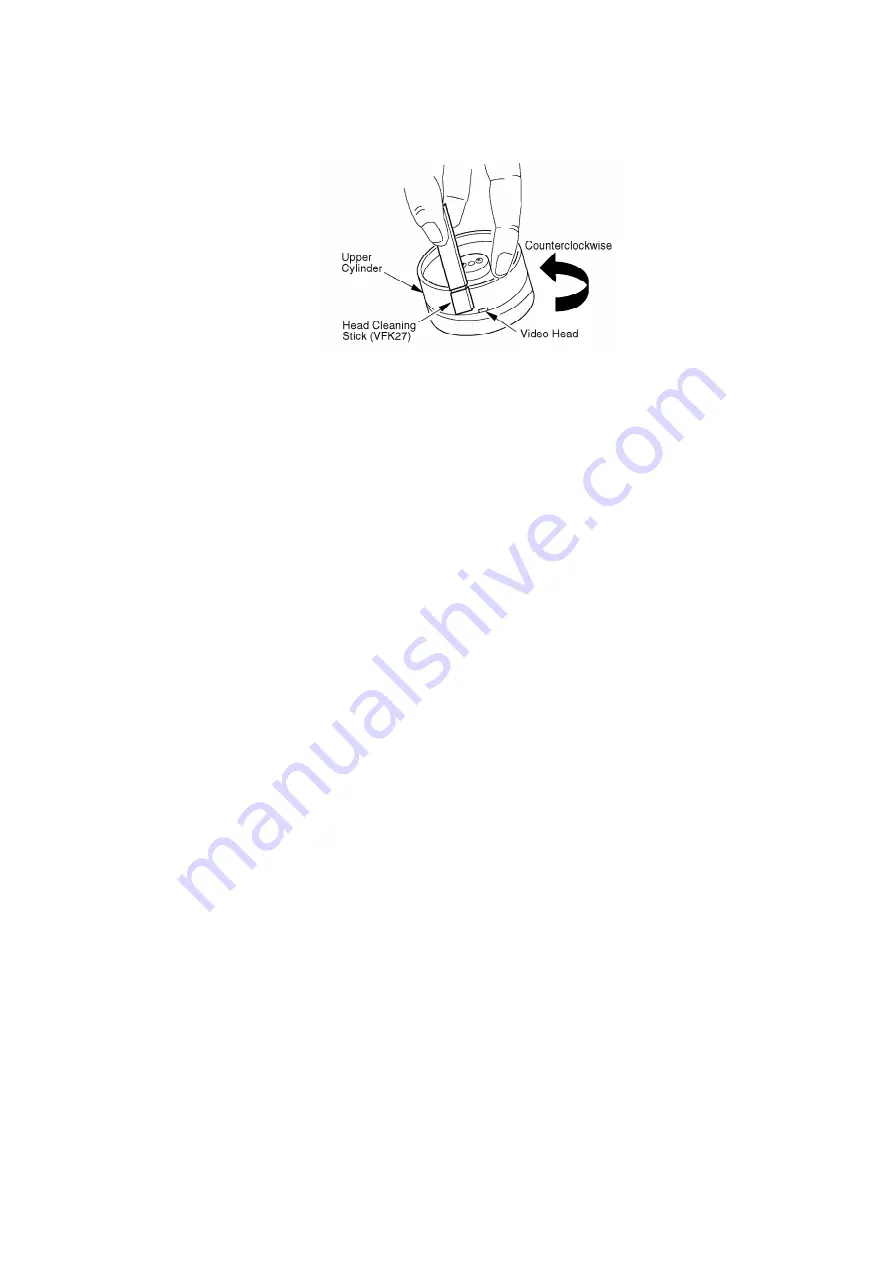

Fig. M1

Note:

A. Do not rub vertically or apply excess pressure to the Video

Heads.

Do not turn the Upper Cylinder Unit clockwise while cleaning.

B. After cleaning, use a Dry Head Cleaning Stick (VFK27) to

remove any Ethanol remaining on the cylinder tape path.

Otherwise, tape damage will occur.

7.2.2. ADJUSTMENT PROCEDURES

7.2.2.1. BACK TENSION CONFIRMATION

Purpose:

To fine adjust the Back Tension so that the tape runs smoothly

with a constant tension.

Symptom of Misadjustment:

1) If the tape tension is less than the specified value, the tape

cannot come into proper contact with the Video Heads, resulting

in poor picture playback.

2) If the tape tension is too high, the tape will soon be damaged.

Equipment Required:

Back Tension Meter (Made in U.S.A., Purchase Locally)

VHS Cassette Tape (120-Minute Tape)

Specification:

20 gf±2.5 gf

(0.196 N±0.025 N)

1. Play back a T120 cassette tape from the beginning for approx. 10

to 20 seconds to stabilize tape movement.

2. Insert a Tension Meter into tape path and measure the back

tension.

48

Summary of Contents for OmniVision PV-C2780-K

Page 8: ...Fig 1 3 Fig 1 4 8 ...

Page 26: ...Fig D5 6 1 2 1 Notes in chart 26 ...

Page 29: ...6 2 2 Inner Parts Location Fig J1 1 29 ...

Page 30: ...6 2 3 EJECT Position Confirmation Fig J1 2 30 ...

Page 31: ...6 2 4 Grounding Plate Unit Full Erase Head and Cylinder Unit Fig J2 1 31 ...

Page 44: ...6 3 CASSETTE UP ASS Y SECTION 6 3 1 Top Plate Wiper Arm Unit and Holder Unit Fig K1 1 44 ...

Page 81: ...81 ...

Page 85: ...11 2 MECHANISM BOTTOM SECTION 85 ...

Page 86: ...11 3 CASSETTE UP COMPARTMENT SECTION 86 ...

Page 87: ...11 4 CHASSIS FRAME SECTION 1 87 ...

Page 88: ...11 5 CHASSIS FRAME SECTION 2 88 ...

Page 89: ...11 6 PACKING PARTS AND ACCESSORIES SECTION 89 ...