2-17

2-18

Screw (B)

Hole (C)

FG Head

Capstan Belt

Capstan Rotor

Unit

0.13 ± 0.02mm

Screwdriver

Black Screw (A)

Fig. M17-3

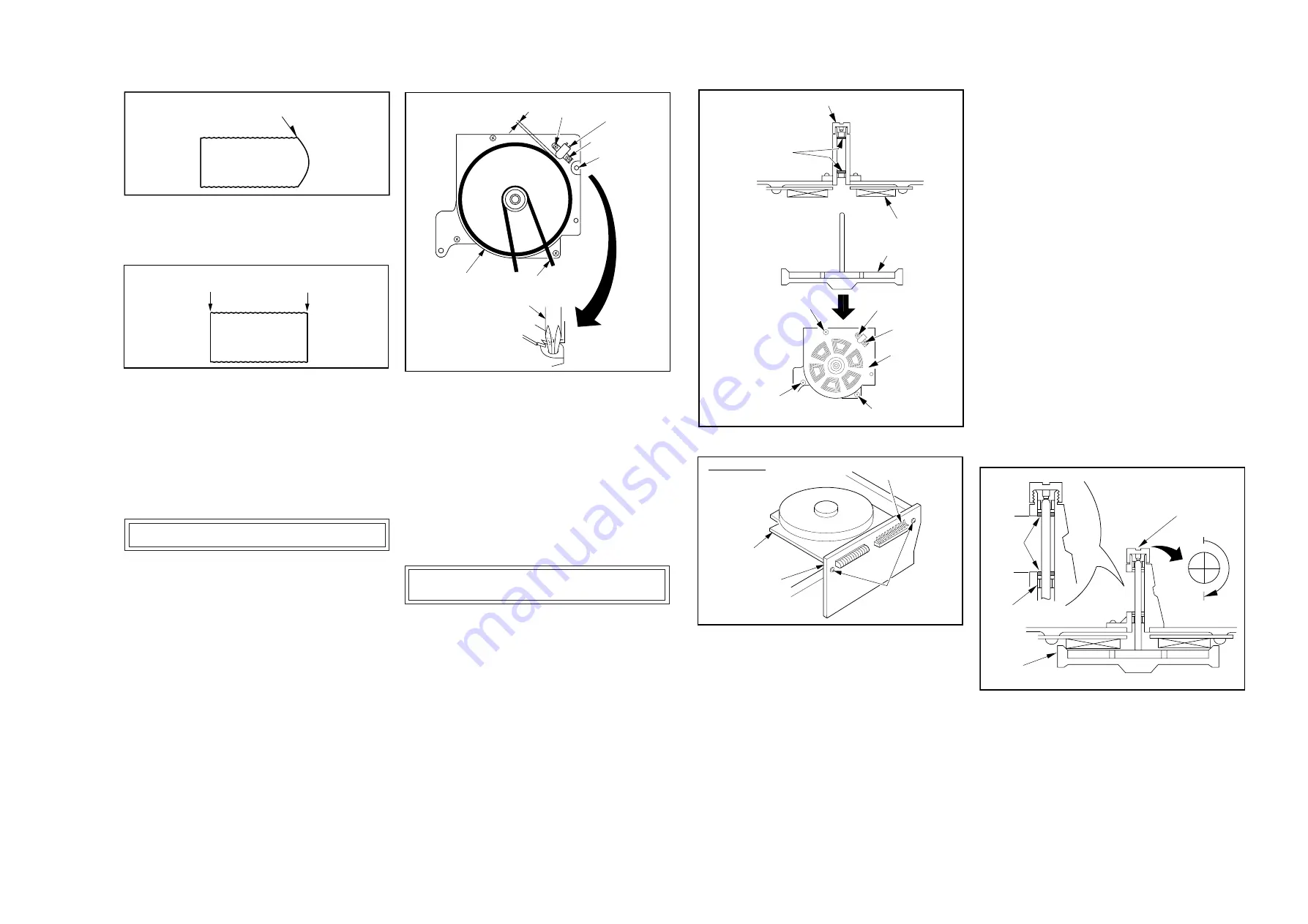

5. When P2 and P3 are adjusted properly, there is no

Envelope Drop at the beginning or end of the track as

shown in Fig. M17-4.

Fig. M17-4

6. Remove a jumper between TP6003 and +5V(TP6020).

Note:

Upon completion of the adjustment of P2 and P3, confirm

the Horizontal Position of the A/C Head by pushing the

Tracking Control Up or Down Buttons alternately, using

the Infrared Remote Control Unit, to check the symmetry

of the envelope. If required, perform “HORIZONTAL

POSITION ADJUSTMENT OF A/C HEAD,” Page 2-16.

ADJUSTMENT OF FG HEAD GAP

Purpose :

To properly pick up the FG Signal.

Symptom of Misadjustment :

If the FG Signal is not properly picked up, Servo Operation

cannot be achieved.

* Equipment Required :

Oscilloscope

* Specification : ........................................... 0.13

±

0.02mm

1. Remove the VCR Chassis Unit and then place it upside

down.

2. Remove the VCR Main C.B.A..

3. Slightly loosen Black Screw (A) and Screw (B). Then set the

Screwdriver (#1 or #2 Phillips Driver) into the Hole (C)

shown in Fig. M18. Turn the screwdriver counterclockwise

until the FG Head touches the rotor. Then turn it slightly

clockwise to the clearance as specified.

4. Tighten Black Screw (A) and Screw (B) shown in Fig. M18.

5. Reinstall the VCR Main C.B.A.Fig. M18

Dropping envelope level at

the end of track (P3)

Envelope Is Adjusted Properly

(No Envelope Drop)

Fig. M18

Note :

Do not touch the outside circumference of the rotor

surface with any tool and keep magnetic material away

from the rotor magnet (especially metal particles).

(Confirmation)

1) Supply a Video Signal to the Video Input Jack on the rear

side of the deck.

2) Insert a cassette tape and place the unit in SLP recording

mode.

3) Connect the oscilloscope to Pin 15 of P2502 on the Capstan

Motor Drive C.B.A..

Confirm that the signal level is greater than 10mVp-p.

REPLACEMENT OF CAPSTAN ROTOR

OR STATOR UNIT

1. Remove the Capstan Belt (Fig. M18).

2. In the order described in the Disassembly and Assembly

Procedures of Mechanism section, remove the Motor Block

Ass'y.

3. Carefully pull out the Capstan Rotor Unit. Be careful not to

lose the 2 Oil Seals shown in Fig. M19.

P2502

Bottom View

Screws (E)

Capstan Stator Unit

Capstan Motor

Drive C.B.A.

Thrust Adjust Screw

Oil Seals

Coil

CAPSTAN STATOR

CAPSTAN ROTOR

Magnet

Screw (D)

Capstan

Stator Unit

Screw (D)

Screw (B)

Screw (D)

Black

Screw (A)

Caution Note :

1) The replacement Capstan Rotor Unit is available only

as a complete unit with a spring loaded Capstan

Pulley.

2) Hold the new Capstan Rotor Unit firmly when installing

it, so the rotor will not be pulled toward the stator too

quickly (due to magnetic force). Placing some paper

on the coils before rotor installation may prevent

accidental damage to the coils if the above caution is

not observed.

3) During installation, do not touch the Capstan Shaft

with any hard material like drivers or tweezers.

9. Re-install the Capstan Motor Drive C.B.A. by tightening 2

Screws (E). Then carefully solder P2502 and re-install the

Motor Block Ass’y.

ADJUSTMENT OF THRUST ADJUST SCREW

AND OIL SEALS

10. Re-install the Capstan Belt and, while exerting pressure

to turn the Clutch Unit, tighten the Thrust Adjust Screw

slowly until the Capstan Rotor just starts turning.

11. At the point where the Capstan Rotor starts turning,

tighten the Thrust Adjust Screw another 180

°

clockwise.

12. Upon completion of the above procedure, confirm that the

Oil Seals are positioned as shown in Fig. M21 and make

sure that the oil seal does not contact the Pressure

Roller or P5 Arm Unit. Then, wipe off the Capstan

Shaft to remove oil, grease, and dust.

Note :

Clean the Capstan Post whenever an Oil Seal is

moved.

Fig. M21

Fig. M19

Fig. M20.

4. Carefully unsolder P2502 on the Capstan Motor Drive

C.B.A.. Then remove the Capstan Motor Drive C.B.A.

by removing 2 Screws (E) shown in Fig. M20.

5. Remove 3 Screws (D), Black Screw (A) and Screw (B).

Then lift out the Capstan Stator Unit.

6. Install the new Capstan Stator Unit and then tighten 3

Screws (D), Black Screw (A) and Screw (B).

7. Before installing the new Capstan Rotor Unit, loosen the

Thrust Adjust Screw completely.

8. Install the new Capstan Rotor, carefully inserting the

Oil Seals as shown in Fig. M19.

Thrust Adjust Screw

180°

0°

equal

Oil

Seals

Rotor

Bushing

equal

Summary of Contents for OmniVision PV-M1326

Page 42: ......

Page 43: ......

Page 44: ......

Page 45: ......

Page 46: ......

Page 47: ......

Page 48: ......

Page 49: ......

Page 50: ......

Page 51: ......

Page 52: ......

Page 53: ......

Page 54: ......

Page 55: ......

Page 56: ......

Page 57: ......

Page 58: ......

Page 59: ......

Page 60: ......

Page 61: ......

Page 62: ......

Page 63: ......

Page 64: ......

Page 65: ......

Page 66: ......

Page 67: ......

Page 68: ......

Page 69: ......

Page 70: ......

Page 71: ......

Page 72: ......

Page 73: ......

Page 74: ......

Page 75: ......

Page 76: ......

Page 77: ......

Page 78: ......

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ......

Page 83: ......

Page 84: ......

Page 85: ......

Page 86: ......

Page 87: ......

Page 88: ......

Page 89: ......

Page 90: ......

Page 91: ......

Page 92: ......

Page 93: ......

Page 94: ......

Page 95: ......

Page 96: ......

Page 97: ......

Page 98: ......

Page 99: ......

Page 100: ......

Page 101: ......

Page 102: ......

Page 103: ......

Page 104: ......

Page 105: ......

Page 106: ......

Page 140: ......

Page 141: ......

Page 142: ......

Page 143: ......

Page 144: ......

Page 145: ......

Page 146: ......

Page 147: ......

Page 148: ......

Page 149: ......

Page 150: ......

Page 151: ......

Page 152: ......

Page 153: ......

Page 154: ......

Page 155: ......

Page 156: ......

Page 157: ......

Page 158: ......

Page 159: ......

Page 160: ......

Page 161: ......

Page 162: ......

Page 163: ......

Page 164: ......

Page 165: ......

Page 166: ......

Page 167: ......

Page 168: ......

Page 169: ......

Page 170: ......

Page 171: ......

Page 172: ......

Page 173: ...Printed in Japan R...