Operation manual for Narrow pitch connectors P5K

Panasonic Corporation

industrial.panasonic.com/ac/e/

©

Panasonic Corporation 2017

ACCTF29E-1

201708

- 6 -

02-2. Precautions for printed circuit design

1) Circuit design

(1)To obtain a good front fillet and back fillet, please review the foot pattern

dimensions recommended in the specifications or catalog for terminal foot pattern

design.

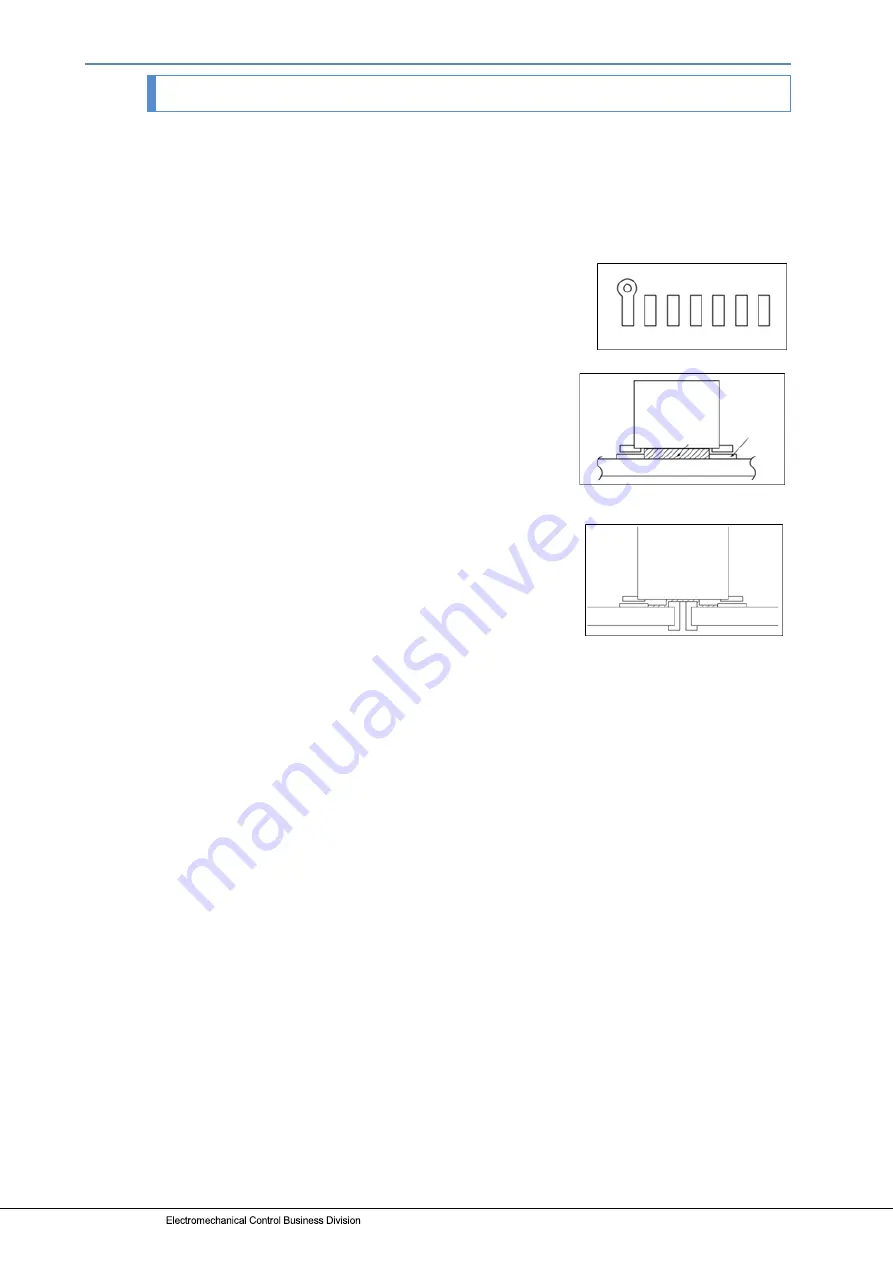

(2)Do not provide through holes on the extension of the

foot pattern. During reflow, the printed solder will be

absorbed by the through hole section, and this will

cause poor solder at the terminal section.

(3)Please control the insulation coating thickness

(resist thickness) on the pattern surface.

The coating thickness can ordinarily be controlled

to the µm level.

If the thickness is too great, it will press up on the

connector bottom, and will cause terminal poor

solder.

(4)Be sure to consult with us beforehand if you want to

perform through hole wiring on the bottom side of

the connector. Basically, you should avoid through

holes on the connector bottom side. They will cause

terminal poor solder.

(5)When mounting to an FPC board, we recommend using the type with a boss.

This makes it possible to limit connector movement during the reflow process,

and reduce soldering trouble.

Resist

Foot

pattern

Board

Summary of Contents for P5K

Page 23: ...ACCTF29E 1 201708 2017 ...