47

PAW-VP•LDHW - Technical Manual – 2020-07

Water Piping Installation

4

4 Water Piping Installation

General notes

●

Please request a licensed technician to install this water circuit.

●

This water circuit must comply with all relevant European and national regulations,

i.e. IEC/EN 61770 European Council Directive 98/83 EC.

●

Be careful not to deform the piping with excessive force when doing piping connec-

tion job.

●

When connecting pipes to tank, always use brass between pipe and tank sleeve to

prevent corrosion between base material.

●

Choose proper sealer which can withstand the pressures and temperatures of the

system. When tank is to be connected ensure the pipings are clean before water

piping installation is carried out.

●

Water operating pressures DHW tank (Minimum ~ Maximum): 0.05 MPa – 0.95 MPa

4.1 Tank unit refrigerant piping installation

1.

Please make flare after inserting flare nut (located at joint portion of tube assembly)

onto the copper pipe. (In case of using long piping)

2. Do not use pipe wrench to open refrigerant piping. Flare nut may be broken and

cause leakage. Use proper spanner or ring wrench.

3. Connect the piping:

● Align the center of piping and sufficiently tighten the flare nut with fingers.

● Further tighten the flare nut with torque wrench in specified torque as stated in

the Installation instructions of PACi.

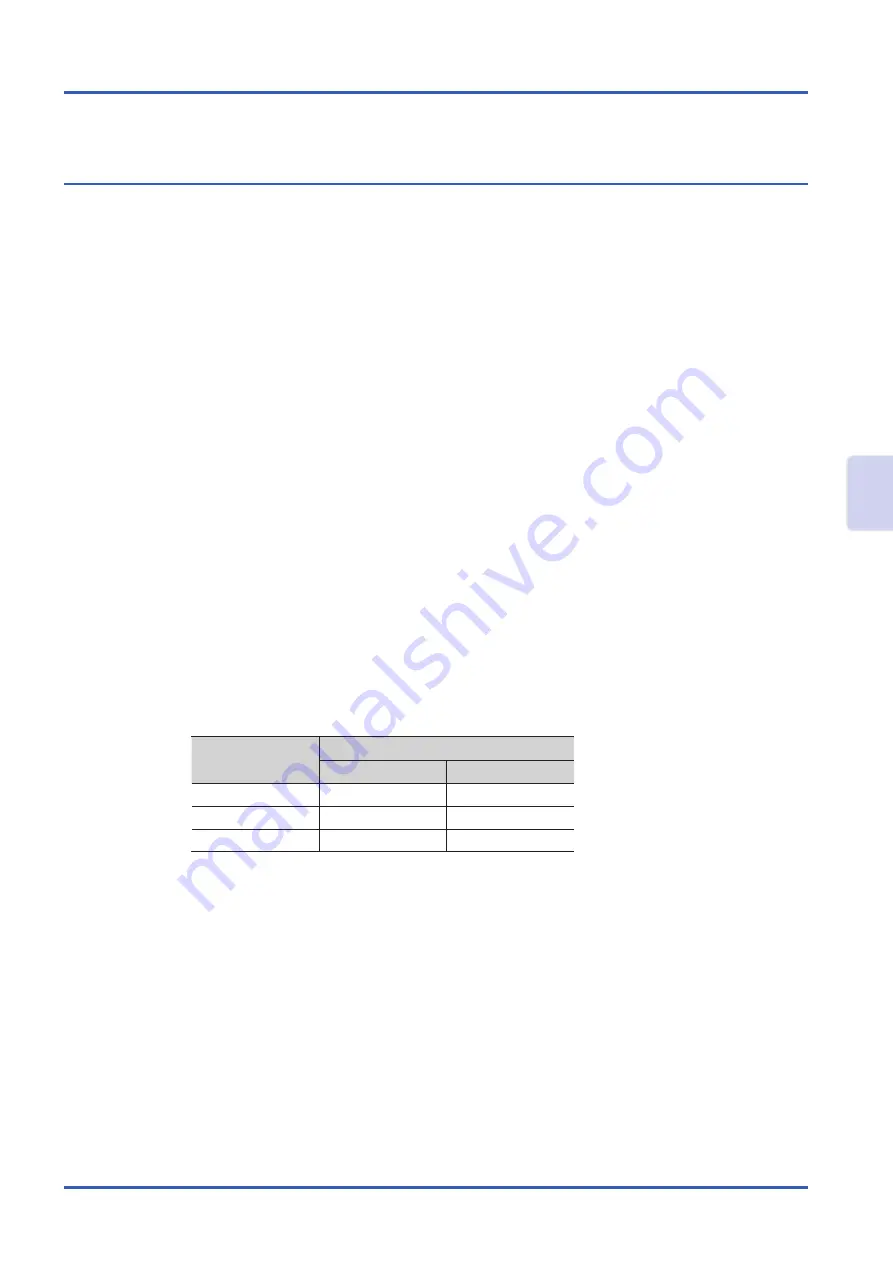

Model

Piping size (Braising tank)

Gas

Liquid

PAW-VP1000L

3/4”

1/2”

PAW-VP750L

3/4”

1/2”

PAW-VP380L

3/4”

1/2”

Please refer to chapter 8 Connecting the Refrigerant Tubing.

4.2 DHW tank water quality

The chemical composition of the water content must never exceed the values established by

European Council Directive 98/83 EC.

.