5

1. Safety Precautions

1.1. General Guidelines

1.2. Leakage Current Check

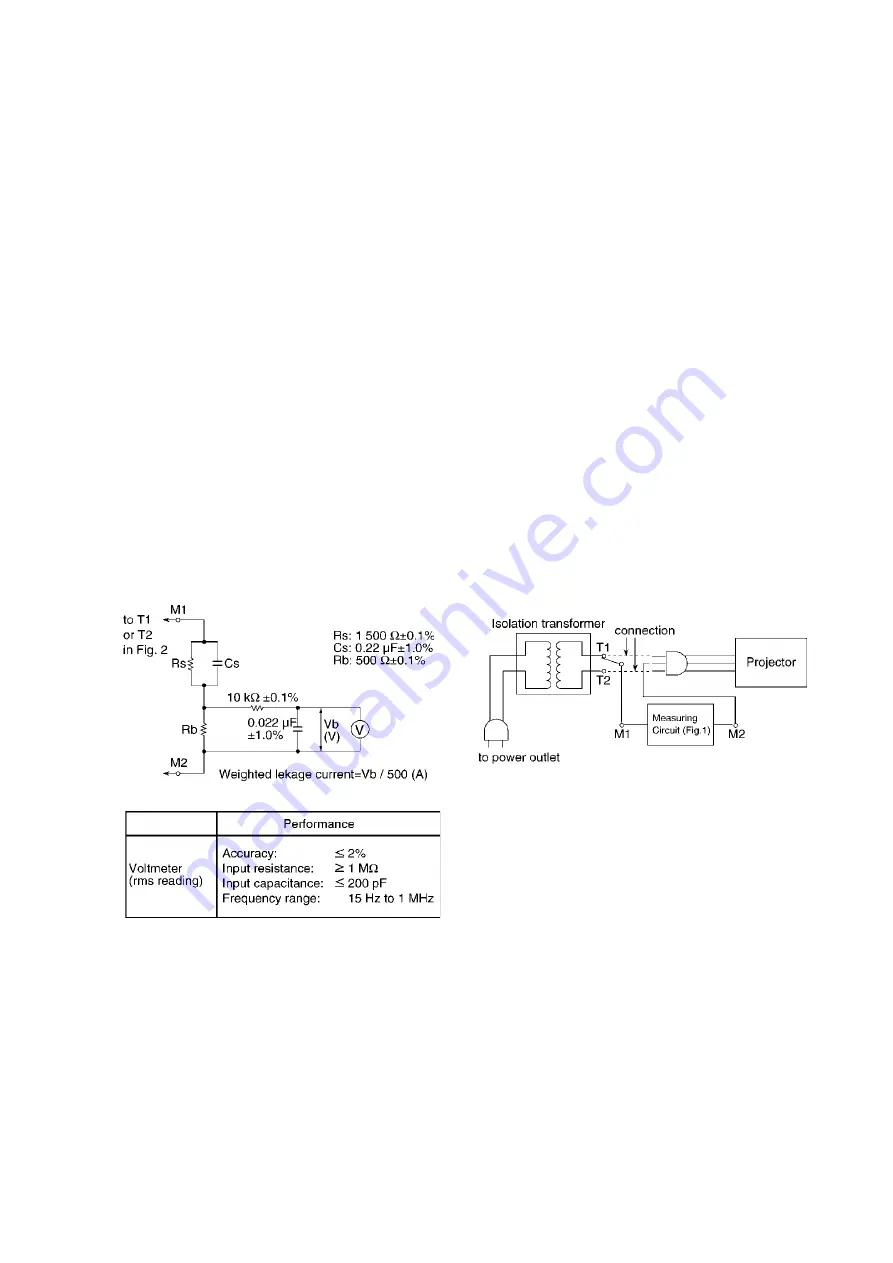

1. Prepare the measuring circuit as shown in Fig.1.

Be sure to use a voltmeter having the performance described in Table 1.

2. Assemble the circuit as shown in Fig. 2. Plug the power cord in a power outlet.

3. Connect M1 to T1 according to Fig. 2 and measure the voltage.

4. Change the connection of M1 from T1 to T2 and measure the voltage again.

5. The voltmeter must read 0.375 V or lower in both of steps 3 and 4. This means that the current must be 0.75mA

or less.

6. If the reading is out of the above standard, the projector must be repaired and rechecked before returning to the

customer because of a possibility of an electric shock.

- For continued safety, no modification of any circuit must be attempted.

- Unplug the power cord from the power outlet before disassembling this projector.

- Use correctly the supplied power cord and must ground it.

- It is advisable to use an isolation transformer in the AC power line before the service.

- Be careful not to touch the rotation part (cooling fan, etc.) of this projector when you service with the upper

case removed and the power supply turned ON.

- Observe the original lead dress during the service. If a short circuit is found, replace all the parts overheated

or damaged by the short circuit.

- After the service, all the protective devices such as insulation barriers, insulation papers, shields, and isolation

R-C combinations must be properly installed.

- After the service, check the leakage current to prevent the customer from getting an electric shock.

Fig. 1

Fig. 2

Table. 1

Summary of Contents for PT-RZ470 Series

Page 6: ...6 2 Specifications...

Page 7: ...7...

Page 9: ...INF 2 1 The name of each part 1 1 Projector body 1 2 Control panel...

Page 10: ...INF 3 1 3 Connecting terminals 1 4 Remote control...

Page 11: ...INF 4 2 OSD Menu Navigation...

Page 12: ...INF 5...

Page 13: ...INF 6...

Page 26: ...INF 19 5 Select Log SYSTEM and click Get button 6 Log is displayed...

Page 84: ......