(WITH SPATIALIZER)

NOT USED

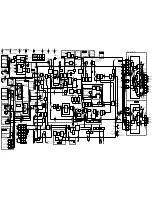

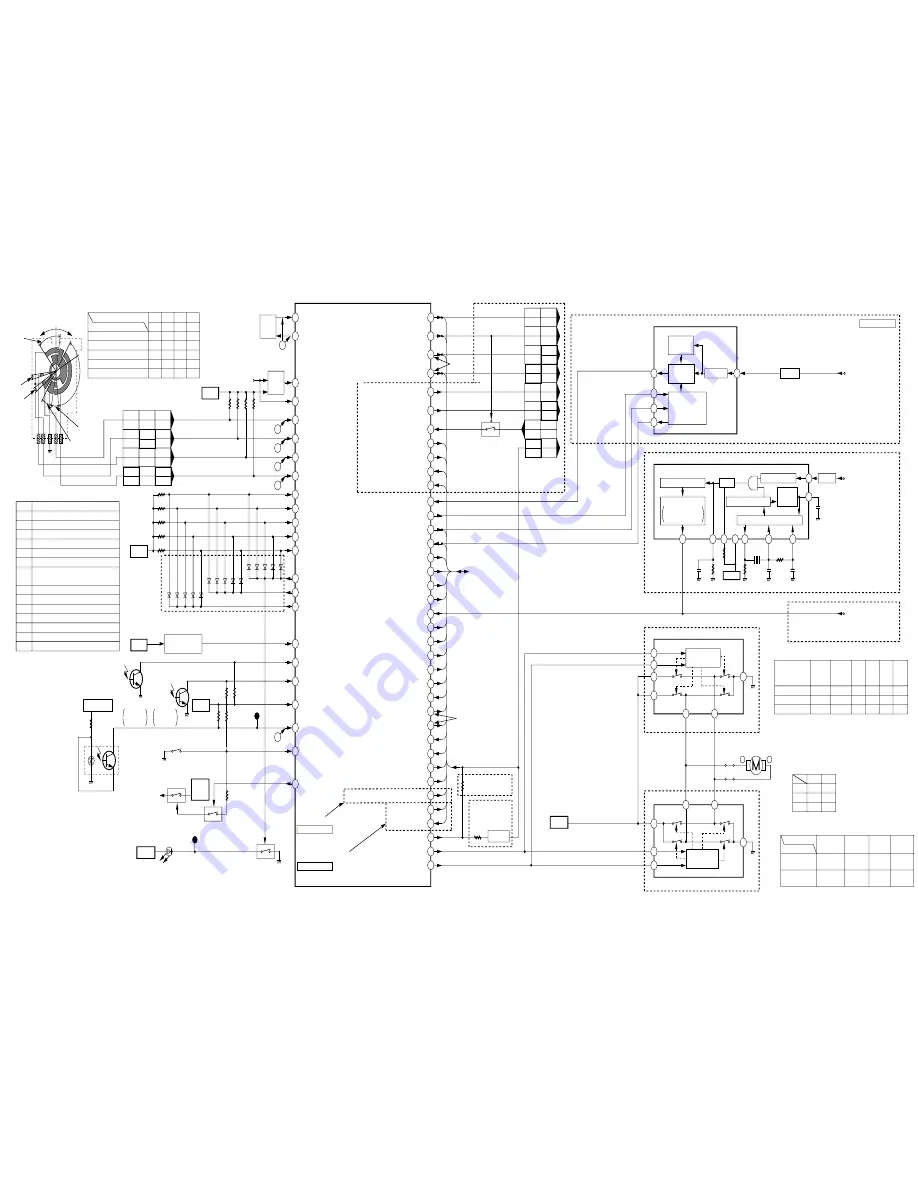

SYSTEM CONTROL BLOCK DIAGRAM

9

10

35

19

56

96

95

94

93

87

86

47

78

77

83

82

84

37

12

6

44

INPUT

SELECT 1

INPUT

SELECT 2

MODE

SIGNAL

TUNER

LINE1 LINE2

L L H H

L H H L

5:INPUT SELECT

SIMUL

CAST

MODE

L

H

H

L

L

MODE SELECT SWITCH

L

H

(96)(95)(94)(93)

A

B

C

D

PIN NO OF IC6001

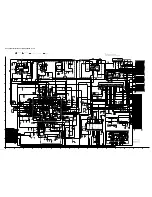

FF/REW

PLAY/CUE/SLOW/STILL

STOP/STANDBY

REVIEW

EJECT

H

H

L

L

H

H

H

H

H

H

H

H

H

P2501

1

P6201

1

P2504

4

P2501

15

P6201

15

P2504

6

P2501

16

P6201

16

P2504

7

P2501

2

P6201

2

P2504

3

R6087

+5V

R6086

R6085

R6084

31

30

52

53

49

5

11

39

46

3

VDD

RESET

POWER DOWN(L)

MODE SW POSITION A

/KEY DATA 0

MODE SW POSITION B

/KEY DATA 1

MODE SW POSITION C

/KEY DATA 2

MODE SW POSITION D

/KEY DATA 3

MTS SIGNAL(L)

SAP SIGNAL(L)

IR DATA

SIGNAL LINE(H)

SAFETY TAB

BROKEN(H)

TAKEUP PHOTO TR(L)

SUPPLY PHOTO TR(L)

TAKEUP REEL PULSE

/SERVICE(L)

VIDEO

DELAY REC(H)

STEREO(H)/MONO(L)

MAIN(H)/SAP(L)

Hi-Fi(H)/NORMAL(L)

AUDIO MUTE(H)

VIDEO EE(H)

INPUT SELECT 1

INPUT SELECT 2

Hi-Fi AUDIO HEAD SW

PB Hi-Fi AUDIO(H)

TV(H)/VCR(L)

CUE/REV/SLOW/STILL(L)

PB(L)

7.16MHz

LOADING MOTOR

REVERSE(H)

LOADING MOTOR

FORWARD(H)

TNR CH FREQUENCY LOCK(L)

/UNLOCK(H)

MODE

ON OFF OFF ON

OFF ON ON OFF

OFF ON OFF ON

SW1 SW2 SW3 SW4

PIN9

OF

IC6001

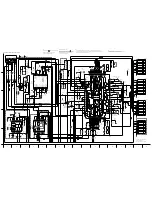

LOADING

UNLOADING

BRAKE

PIN10

OF

IC6001

L

H

H

H

L

H

3

SUPPLYING THE DC VOLTAGE AFTER CUTTING THE

JUMPER WIRE CAUSES AN UNLOADING OPERATION

SEQUENCE FOR THE REMOVAL OF A JUMMED TAPE.

9

5

CONTROL

LOGIC

3

7

1

6

LOADING

MOTOR

Å–3 J6005

+

-

SW1

SW3

SW2

SW4

+14V

SP

LP

PIN8

L

H

L

H

4:TAPE SPEED

PIN7

L

H

SLP

79

–5

27

OSD-CS(L)

16

17

SERIAL DATA 1

SERIAL CLOCK

81

SIGNAL(L)

18

SERIAL DATA 0

50

AIP CTL SIGNAL

+14V

D6001

(SENSOR LED)

TP6011

–2

SW

+12V

SW6001

SAFETY TAB SW

R6073

R6075

+5V

TP6001

–1

R6069

R6070

SW+12V

(REEL SENSOR)

TAKEUP

PHOTO TR

SUPPLY

PHOTO TR

2

THIS IS USED FOR MICROPROCESSOR

JUDGMENT POINT.

1

BY SHORTING TP6001 AND GND,

ANY OPERATION CAN BE DONE

WITHOUT A CASSETTE(FOR SERVICE).

TO HEAD AMP

/AUDIO CIRCUIT

IR

RECEIVER

+5V

92 KEY DATA 4

91 KEY DATA 5

90 KEY DATA 6

89 KEY DATA 7

2 SCAN 3/SENSOR LED ON(H)

1 SCAN 2

100 SCAN 1

D6018

D6017

D6016

D6015

D6014

D6013

D6012

D6011

D6010

D6009

D6008

D6007

29

AUDIO DEFEAT(H)

7

8

LP/SLP(H)

SLP(H)

–4

34

33

OSC 2

OSC 1

OSC

X6001

(14MHz)

RESET

(FROM P1051(3))

POWER DOWN(L)

R6078

R6079

R6080

R6081

+5V

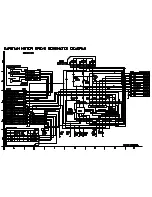

Å–6:I/O MATRIX CHART

D6007

D6008

D6009

D6010

WITH Hi-Fi

WITH SPATIALIZER

WITH AUTO CLOCK SET

WITH S-VHS

--------

--------

WITH PV-4601 B

WITH VCR PLUS

AND CABLE CHANNEL CHANGER

WITH 2HEAD

WITH FIP-A/B

WITH SET UP/DOWN

WITHOUT VCR PLUS

D6011

D6012

D6013

D6014

D6015

D6016

D6017

D6018

a

b

c

d

A

B

80

AUTOMATIC FREQUENCY

CONTROL

DTS CS(H) 4

WIRE JUMPER OR DIODE IS USED

FOR ABOVE REF.NO.(D¥¥¥¥).

–6

STBY

LOADUNLOAD

A

B

C

D

REV

PLAY/CUE

/SLOW/STILL

FF/REW

EJECT

STOP

TO/FROM VIDEO/AUDIO

/HEAD AMP/MTS/SAP

/TIMER/OPERATION

/UHF/VHF TUNER

/TV DEMODU CIRCUIT

PIN

25

P4203

25

PIN

5

P4201

5

PIN

19

P4202

19

PIN

11

P4202

11

PIN

3

P4201

3

PIN

21

P4203

21

PIN

22

P4203

22

R6074

14

PANEL CONTROL CS(L)

28

DATA SLICER CS(L)

5

15

DATA

SLICER

CLAMP

DATA

OUTPUT

22

10

21

(FROM IC3001(25))

VIDEO

EDS CLOCK DATA 55

88 KEY DATA 8

R6082

D6021

D6020

D6019

WITH LINE 2

D6019

WITH PX MODEL

D6020

WITH EP INDICATION

D6021

CONTROL

LOGIC

9

1

7

5

3

2

SW1

SW2

SW3

SW4

BEEPER 45

PANEL RESET(L) 15

SPATIALIZER CONTROL(H/L/OFF)51

PIN

1

P4201

1

Å–3 J6004

8

DRIVE

Q4601

R4608

R4607

V-MASK(H) 36

BLACK DETECT

(L)

54

(WITH CM ADVANCE)

NOT USED

(FROM U/V TUNER/TV

DEMODU(9))

SIGNAL(L)

(PV-4601 A,PV-4601-K,PV-4651,PV-4651-K)

(PV-4601 A,PV-4601-K,PV-4651,PV-4651-K)

(PV-4601 B)

(PV-4601 B)

OUTPUT CONTROL

SIGNAL EXIST(L)

NO SIGNAL(H)

COMPARATOR

AMP

V.SYNC SEPA.

1/32 DIVIDER

VCO

PHASE

COMP.

10

8

1

2

3

4

6

R7055

X7501

503KHz R7061

C7054 C7055

BUFFER

R7065

C7058

DATA

SLICER

LPF

R3301

C3305

C3306

7

+5V

9

(FROM U/V

TUNER/TV

DEMODU(18))

TUNER VIDEO

VCC

C7053

Q6010

IC6002

Q6002

Q6003

Q6001

Q6009

U6301

Q4208

(WITH Hi-Fi AUDIO)

(WITH

Hi-Fi AUDIO)

(WITH

MONORAL)

IC6003

IC6003

IC7051

IC3301

Q7051

(WITH AUTO CLOCK SET) NOT USED

IC6001

Q6005, Q6006

Q6007, Q6008

Summary of Contents for PV-4601 A

Page 14: ...Fig 2 3 14 ...

Page 27: ...Fig 11 1 1 27 ...

Page 40: ...Fig D1 40 ...

Page 42: ...Fig D2 42 ...

Page 43: ...Fig D3 43 ...

Page 44: ...Fig D4 44 ...

Page 45: ...Fig D5 45 ...

Page 46: ...Fig D7 46 ...

Page 47: ...Fig D8 47 ...

Page 51: ...Fig M2 1 Fig M2 2 51 ...

Page 53: ...Fig M4 1 53 ...

Page 77: ...Fig M19 77 ...

Page 84: ...Fig J5 84 ...

Page 85: ...Fig J6 85 ...

Page 87: ...Fig J9 87 ...

Page 88: ...Fig J10 88 ...

Page 89: ...Fig J11 89 ...

Page 90: ...Fig J12 90 ...

Page 91: ...Fig J13 91 ...

Page 92: ...Fig J15 92 ...

Page 93: ...93 ...

Page 96: ...96 ...

Page 102: ...with the holes on the Pinch Lift Cam as shown in Fig A6 102 ...

Page 103: ...103 ...

Page 105: ...Fig K1 105 ...

Page 106: ...Fig K2 106 ...

Page 107: ...Fig K3 107 ...

Page 109: ...Fig B1 109 ...

Page 114: ...Fig E1 4 3 2 HOW TO READ THE ADJUSTMENT PROCEDURES 114 ...

Page 115: ...Fig E2 115 ...

Page 134: ...R6004 ERJ6GEYJ333V MGF CHIP 1 10W 33K 134 ...

Page 136: ...R6085 ERJ6GEYJ223V MGF CHIP 1 10W 22K 136 ...

Page 140: ...C4601 ECEA1CKA100 ELECTROLYTIC 16V 10 140 ...

Page 147: ...R6065 ERJ6GEYJ223V MGF CHIP 1 10W 22K 147 ...

Page 167: ...9 11 Operation Block Diagrams 1 167 ...

Page 178: ......

Page 204: ......

Page 205: ......