16 Adjustment Procedure

16.1. Service Tools and Equipment

Application

Name

Number

Tilt adjustment

DVD test disc

DVDT-S20 [SPG]

Hex wrench

Available on sales route.

Others

Grease

RFKXPG641 [SPG]

Confirmation

CD test disc

PVCD-K06 or any other commercially

available disc

VCD test disc

PVCD-K06 or any other commercially

available disc

Recovery disc

RFKZD03R005 [SPG]

16.2. Important points in adjustment

16.2.1. Important points in optical adjustment

·

Before starting optical adjustment, be sure to take anti-static measures.

·

Optical pickup tilt adjustment is needed after replacement of the following components.

1. Optical pickup unit

2. Spindle motor unit

3. Optical pickup peripheral parts (such as rail)

Notes

Adjustment is generally unnecessary after replacing other parts of the traverse unit. However, make adjustment if there is a

noticeable degradation in picture quality. Optical adjustments cannot be made inside the optical pickup. Adjustment is generally

unnecessary after replacing the traverse unit.

16.2.2. Important points in electrical adjustment

·

Follow the adjustment procedures described in this Manual.

16.3. Storing and handling of test discs

·

Surface precision is vital for DVD test discs. Be sure to store and handle them carefully.

1. Do not place discs directly onto the workbench, etc., after use.

2. Handle discs carefully in order to maintain their flatness. Place them into their case after use and store them vertically. Store

discs in a cool place where they are not exposed to direct sunlight or air from air conditioners.

3. Accurate adjustment will not be possible if the disc is warped when placed on a surface made of glass, etc. If this happens, use

a new test disc to make optical adjustments.

4. If adjustment is done using a warped disc, the adjustment will be incorrect and some discs will not be playable.

56

SA-HT680PL

Summary of Contents for SA-HT680PL

Page 18: ...10 2 Main Components and P C B Locations 18 SA HT680PL ...

Page 23: ...23 SA HT680PL ...

Page 24: ...24 SA HT680PL ...

Page 25: ...11 3 Assembling for traverse motor and spindle motor 25 SA HT680PL ...

Page 26: ...26 SA HT680PL ...

Page 28: ...28 SA HT680PL ...

Page 31: ...31 SA HT680PL ...

Page 32: ...32 SA HT680PL ...

Page 34: ...34 SA HT680PL ...

Page 35: ...35 SA HT680PL ...

Page 36: ...36 SA HT680PL ...

Page 37: ...37 SA HT680PL ...

Page 38: ...38 SA HT680PL ...

Page 39: ...39 SA HT680PL ...

Page 40: ...40 SA HT680PL ...

Page 41: ...41 SA HT680PL ...

Page 42: ...42 SA HT680PL ...

Page 43: ...43 SA HT680PL ...

Page 44: ...44 SA HT680PL ...

Page 46: ...46 SA HT680PL ...

Page 52: ...52 SA HT680PL ...

Page 58: ...58 SA HT680PL ...

Page 66: ...SA HT680PL 66 ...

Page 72: ...SA HT680PL 72 ...

Page 88: ...SA HT680PL 88 ...

Page 90: ...SA HT680PL 90 ...

Page 94: ...27 1 Loading Mechanism Traverse Unit Cabinet 94 SA HT680PL ...

Page 95: ...27 1 1 Loading Mechanism Traverse Unit Cabinet Parts Location 95 SA HT680PL ...

Page 96: ...96 SA HT680PL ...

Page 97: ...97 SA HT680PL ...

Page 98: ...98 SA HT680PL ...

Page 99: ...99 SA HT680PL ...

Page 100: ...100 SA HT680PL ...

Page 112: ...27 4 Packaging 112 SA HT680PL ...

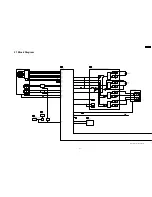

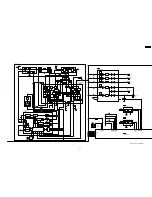

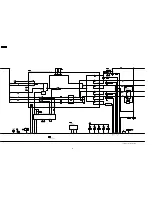

Page 113: ...28 Schematic Diagram for printing with letter size 113 SA HT680PL ...

Page 133: ...133 SA HT680PL ...