2. After servicing, see to it that all the protective devices such as

insulation barriers, insulation papers shields are properly installed.

3. After servicing, make the following leakage current checks to

prevent the customer from being exposed to shock hazards.

(This “Safety Precaution” is applied only in U.S.A.)

1. Before servicing, unplug the power cord to prevent an electric

shock.

2. When replacing parts, use only manufacturer’s recommended

components for safety.

3. Check the condition of the power cord. Replace if wear or damage

is evident.

4. After servicing, be sure to restore the lead dress, insulation

barriers, insulation papers, shields, etc.

5. Before returning the serviced equipment to the customer, be sure

to make the following insulation resistance test to prevent the

customer from being exposed to a shock hazard.

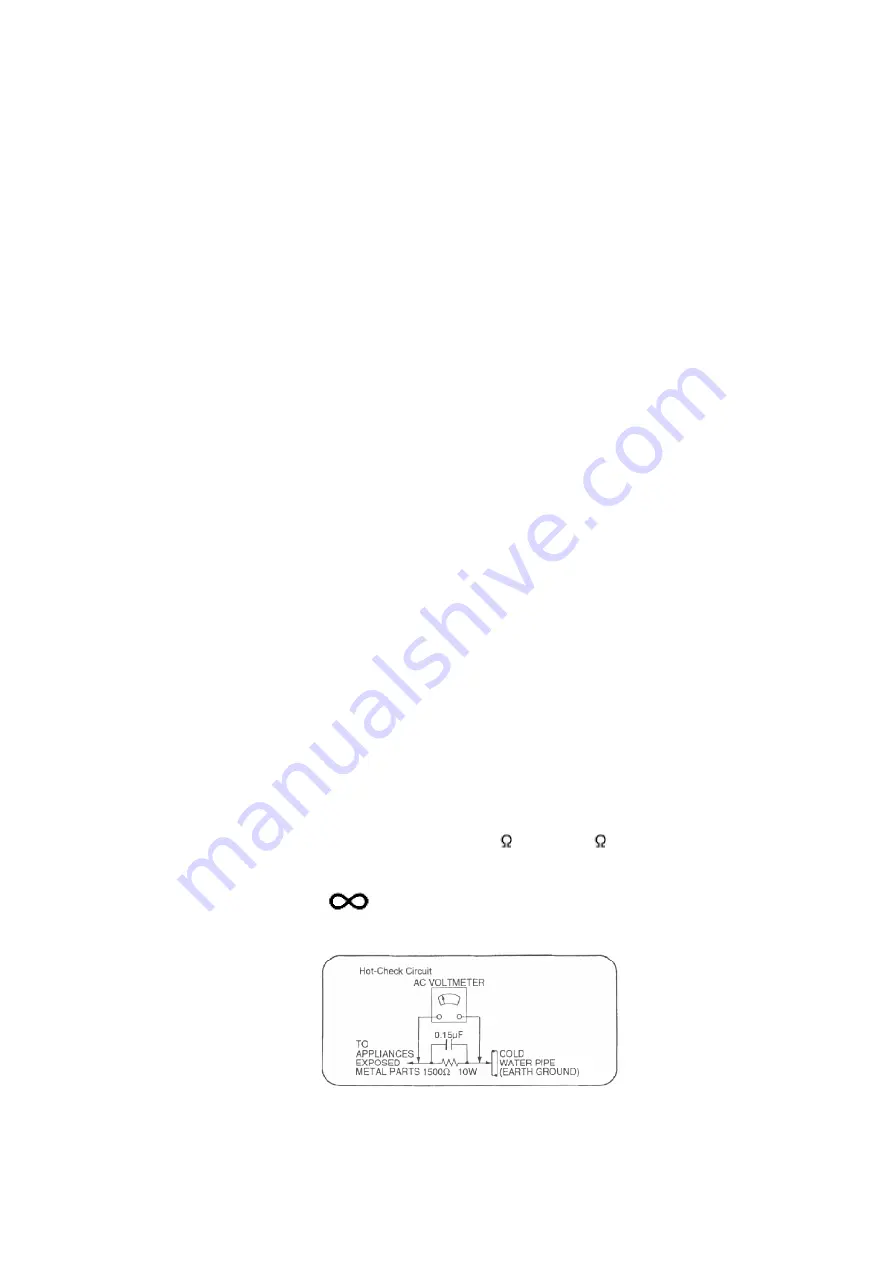

1.1.1. LEAKAGE CURRENT COLD CHECK

1. Unplug the AC cord and connect a jumper between the two prongs

on the plug.

2. Measure the resistance value, with an ohmmeter, between the

jumpered AC plug and each exposed metallic cabinet part on the

equipment such as screwheads, connectors, control shafts, etc.

When the exposed metallic part has a return path to the chassis,

the reading should be between 1M and 5.2 . / When the

exposed metal does not have a return path to the chassis, the

reading must be

.

Fig. 1

3

Summary of Contents for SB-WA920PP

Page 19: ...13 1 2 Cabinet Parts List 19 ...

Page 23: ...H601 K1YF10000006 10P WIRE HOLDER M 23 ...

Page 25: ...R529 ERDS2TJ223T 22K 1 4W M 25 ...

Page 30: ...FLE0403 P A S E N 30 ...