8

2.2.

Service caution based on Legal restrictions

2.2.1.

General description about Lead Free Solder (PbF)

The lead free solder has been used in the mounting process of all electrical components on the printed circuit boards used for this

equipment in considering the globally environmental conservation.

The normal solder is the alloy of tin (Sn) and lead (Pb). On the other hand, the lead free solder is the alloy mainly consists of tin

(Sn), silver (Ag) and Copper (Cu), and the melting point of the lead free solder is higher approx.30 degrees C (86

°

F) more than that

of the normal solder.

Definition of PCB Lead Free Solder being used

Service caution for repair work using Lead Free Solder (PbF)

• The lead free solder has to be used when repairing the equipment for which the lead free solder is used.

(Definition: The letter of “PbF” is printed on the PCB using the lead free solder.)

• To put lead free solder, it should be well molten and mixed with the original lead free solder.

• Remove the remaining lead free solder on the PCB cleanly for soldering of the new IC.

• Since the melting point of the lead free solder is higher than that of the normal lead solder, it takes the longer time to melt the

lead free solder.

• Use the soldering iron (more than 70W) equipped with the temperature control after setting the temperature at 350±30 degrees

C (662±86

°

F).

Recommended Lead Free Solder (Service Parts Route.)

• The following 3 types of lead free solder are available through the service parts route.

RFKZ03D01K-----------(0.3mm 100g Reel)

RFKZ06D01K-----------(0.6mm 100g Reel)

RFKZ10D01K-----------(1.0mm 100g Reel)

Note

* Ingredient: Tin (Sn), 96.5%, Silver (Ag) 3.0%, Copper (Cu) 0.5%, Cobalt (Co) / Germanium (Ge) 0.1 to 0.3%

The letter of “PbF” is printed either foil side or components side on the PCB using the lead free solder.

(See right figure)

Summary of Contents for SC-ZT1GN

Page 4: ...4 1 2 Caution for AC Mains Lead ...

Page 11: ...11 5 Location of Controls and Components 5 1 Main Unit SU ZT1 ...

Page 12: ...12 5 2 Speaker Unit SB ZT1 5 3 Remote Control ...

Page 13: ...13 6 Installation ...

Page 14: ...14 6 1 Basic Connections 6 1 1 Connecting equipment with HDMI terminal TV DVD recorder etc ...

Page 15: ...15 6 1 2 Connecting equipment without HDMI termial DVD player VCR etc ...

Page 16: ...16 6 1 3 Other connections ...

Page 17: ...17 6 2 AC mains lead connection ...

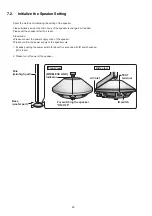

Page 18: ...18 7 Speaker setting SB ZT1 7 1 Setting the speakers ...

Page 19: ...19 ...

Page 27: ...27 9 2 2 Speaker Unit SB ZT1 ...

Page 28: ...28 9 2 3 Speaker Unit SB ZT1 Wireless Link ...

Page 29: ...29 ...

Page 31: ...31 ...

Page 32: ...32 10 2 Main Parts Location Diagram 10 2 1 Main Unit SU ZT1 ...

Page 33: ...33 10 2 2 Speaker Unit SB ZT1 ...

Page 35: ...35 10 3 2 Speaker Unit SB ZT1 ...

Page 48: ...48 Step 4 Remove the Weight ...

Page 49: ...49 Step 5 Remove 10 screws ...

Page 53: ...53 Step 11 Remove 2 screws Step 12 Lift up to remove Arm Cover A ...

Page 55: ...55 Step 14 Tilt the Woofer Block in order as arrows shown to detach it from the Tweeter Block ...

Page 66: ...66 Step 3 Remove the heatsink with the IC5701 ...

Page 67: ...67 Step 4 Remove 1 screw Step 5 Remove IC5701 from the heatsink ...

Page 69: ...69 Step 4 Place the heatsink with the IC5701 onto the SMPS P C B ...

Page 81: ...81 Step 4 Remove 3 screws Step 5 Remove the Power Button ...

Page 86: ...86 Step 3 Remove 4 screws Step 4 Lift up to remove Woofer Speaker SP1 ...

Page 110: ...110 Step 11 Remove 3 screws ...

Page 111: ...111 Step 12 Remove the Light Panel Step 13 Remove the Power Button ...

Page 129: ...129 14 Overall Simplified Block 14 1 Signal Flow SU ZT1 ...