3

1 Safety Precautions

1.1.

General Guidelines

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

3. After servicing, carry out the following for leakage current checks to prevent the customer from being exposed to shock haz-

ards.

1.1.1.

Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the two prongs on the plug.

2. Using an ohmmeter measure the resistance value, between the jumpered AC plug and each exposed metallic cabinet part on

the equipment such as screwheads, connectors, control shafts, etc. When the exposed metallic part has a return path to the

chassis, the reading should be between 1MW and 5.2MW. When the exposed metal does not have a return path to the chas-

sis, the reading must be

.

1.1.2.

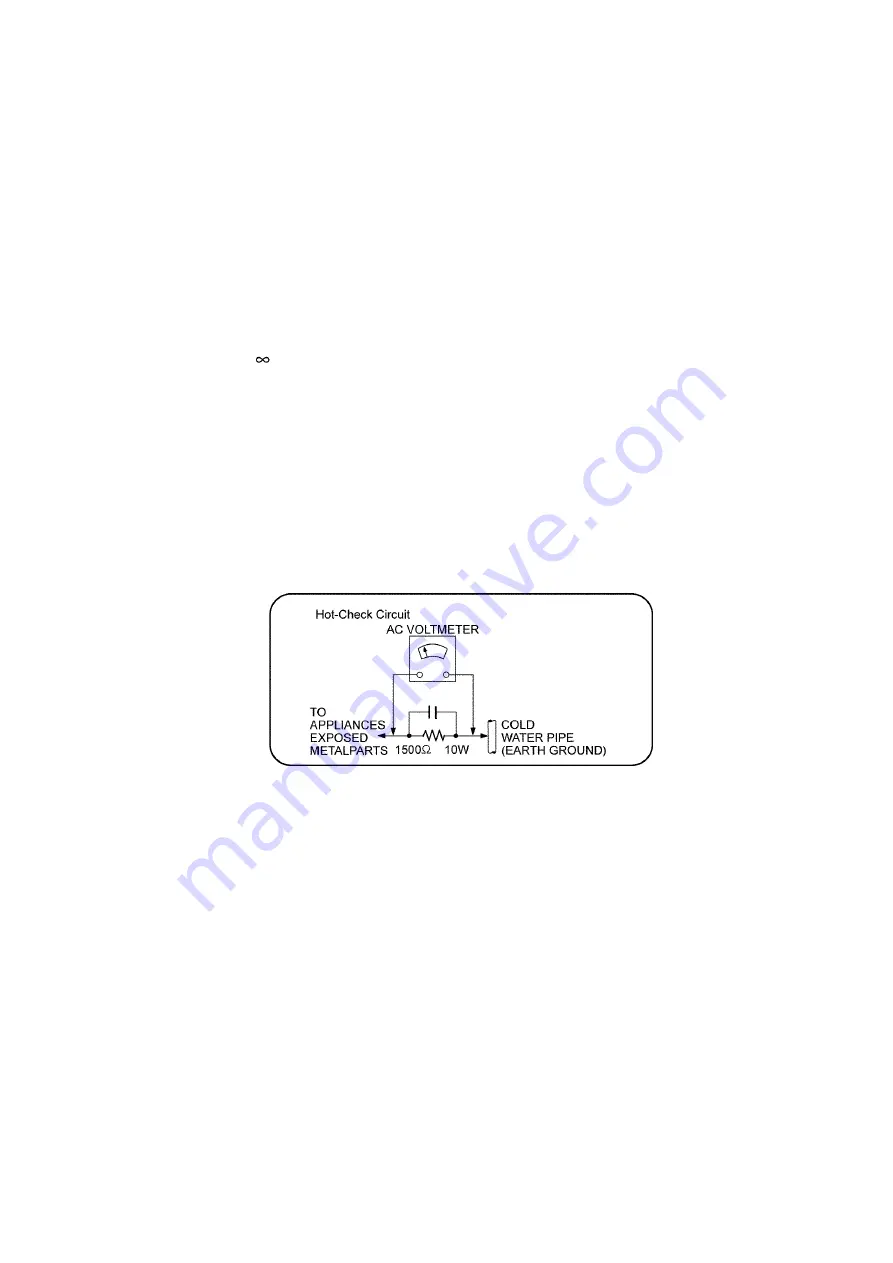

Leakage Current Hot Check

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check.

2. Connect a 1.5kW, 10 watts resistor, in parallel with a 0.15mF capacitors, between each exposed metallic part on the set and a

good earth ground such as a water pipe, as shown in Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the above measurements.

6. The potential at any point should not exceed 0.75 volts RMS. A leakage current tester (Simpson Model 229 or equivalent)

may be used to make the hot checks, leakage current must not exceed 1/2 milliamp. should the measurement is outside of

the limits specified, there is a possibility of a shock hazard, and the equipment should be repaired and re-checked before it is

returned to the customer.

Fig. 1

Summary of Contents for SC-ZT1GN

Page 4: ...4 1 2 Caution for AC Mains Lead ...

Page 11: ...11 5 Location of Controls and Components 5 1 Main Unit SU ZT1 ...

Page 12: ...12 5 2 Speaker Unit SB ZT1 5 3 Remote Control ...

Page 13: ...13 6 Installation ...

Page 14: ...14 6 1 Basic Connections 6 1 1 Connecting equipment with HDMI terminal TV DVD recorder etc ...

Page 15: ...15 6 1 2 Connecting equipment without HDMI termial DVD player VCR etc ...

Page 16: ...16 6 1 3 Other connections ...

Page 17: ...17 6 2 AC mains lead connection ...

Page 18: ...18 7 Speaker setting SB ZT1 7 1 Setting the speakers ...

Page 19: ...19 ...

Page 27: ...27 9 2 2 Speaker Unit SB ZT1 ...

Page 28: ...28 9 2 3 Speaker Unit SB ZT1 Wireless Link ...

Page 29: ...29 ...

Page 31: ...31 ...

Page 32: ...32 10 2 Main Parts Location Diagram 10 2 1 Main Unit SU ZT1 ...

Page 33: ...33 10 2 2 Speaker Unit SB ZT1 ...

Page 35: ...35 10 3 2 Speaker Unit SB ZT1 ...

Page 48: ...48 Step 4 Remove the Weight ...

Page 49: ...49 Step 5 Remove 10 screws ...

Page 53: ...53 Step 11 Remove 2 screws Step 12 Lift up to remove Arm Cover A ...

Page 55: ...55 Step 14 Tilt the Woofer Block in order as arrows shown to detach it from the Tweeter Block ...

Page 66: ...66 Step 3 Remove the heatsink with the IC5701 ...

Page 67: ...67 Step 4 Remove 1 screw Step 5 Remove IC5701 from the heatsink ...

Page 69: ...69 Step 4 Place the heatsink with the IC5701 onto the SMPS P C B ...

Page 81: ...81 Step 4 Remove 3 screws Step 5 Remove the Power Button ...

Page 86: ...86 Step 3 Remove 4 screws Step 4 Lift up to remove Woofer Speaker SP1 ...

Page 110: ...110 Step 11 Remove 3 screws ...

Page 111: ...111 Step 12 Remove the Light Panel Step 13 Remove the Power Button ...

Page 129: ...129 14 Overall Simplified Block 14 1 Signal Flow SU ZT1 ...