19

3. 0 Assembly and Manufacturing Process Considerations

For safe installation and trouble-free operation of compressor and air-conditioning system, below instructions

should be carefully read and strictly followed before beginning.

3.1 Removing Rubber Plug

Each compressor is shipped with a dry Nitrogen holding charge between 0.12~0.18MPa (G) (18~26 psig)

and sealed with rubber plugs. The discharge plug should be removed first before pulling the suction plug to

avoid loss of oil. Compressor should be installed into system within 15 minutes after removing the plugs.

The compressor should be kept vertical and not be declined while removing rubber plugs.

Do not use the compressor from which the discharge sound cannot be heard when removing rubber plugs.

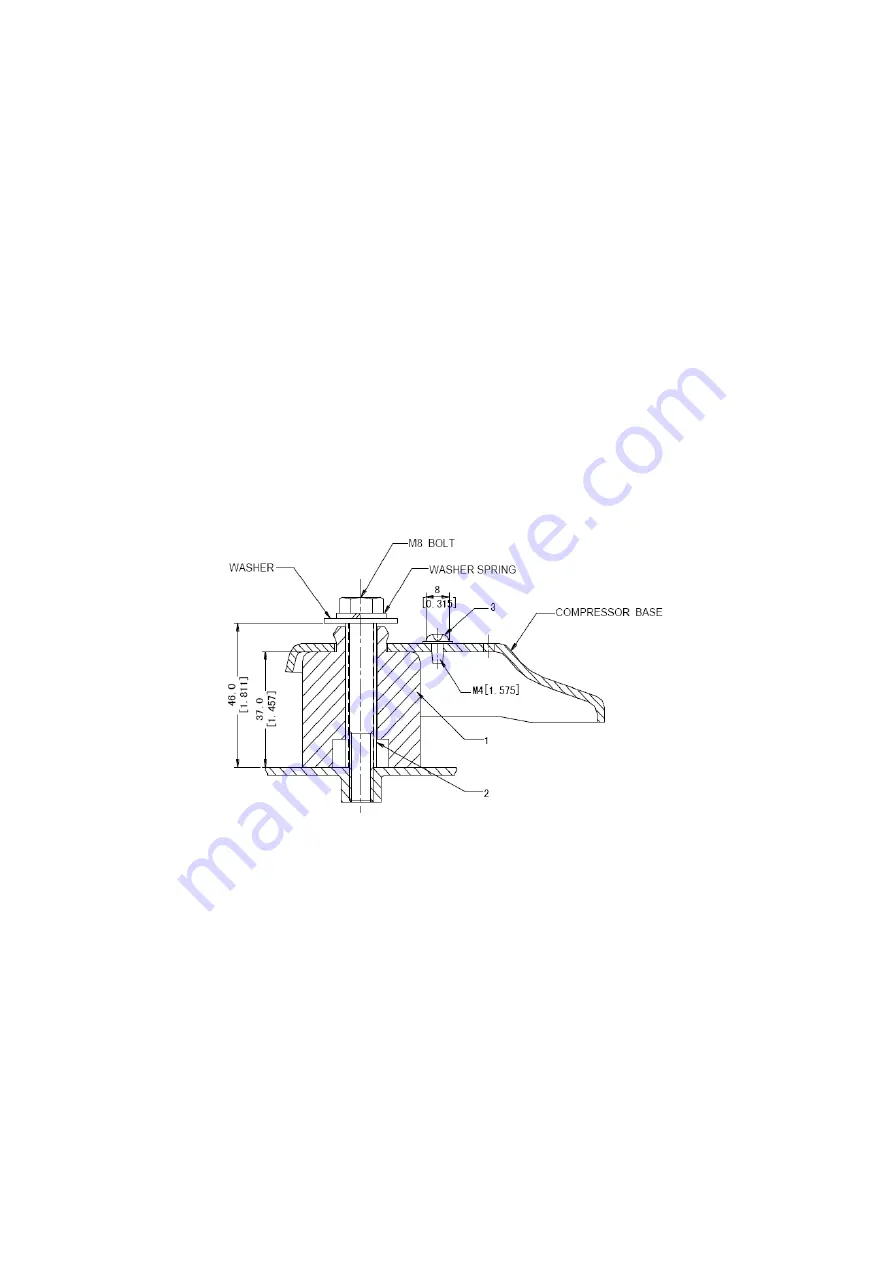

3.2 Compressor Mounting

Please use the mounting accessories (grommets and sleeves) that are supplied or specified by Dalian

Panasonic, as shown in Figure 3-1.

1-Mounting Grommet 2-Mounting Sleeve

Figure 3-1 Mounting Parts for C-SB

3.3 Residual Moisture

System residual moisture level should be kept less than 200ppm for C-SB models and 500ppm for C-SC

models. Normally if the vacuum degree of system can be achieved, the residual moisture level will also meet

this requirement.

3.4 Tube Brazing

During brazing the system piping to the compressor, it is important to maintain the cleanliness inside the

piping to prevent water, solid contamination and so on entering into the system. Do not bend the discharge

or suction lines or force the piping into the compressor connections since this may increase piping stress and

potential failure. See figure below for recommended materials and procedure.