4

1.2 Scroll Compressor Operating Characteristics

Panasonic scroll compressor is designed with fixed eccentric and tip seals for axial sealing, resulting in low

sound level and minimal gas leakage and therefore excellent efficiency. Separation of suction gas from the

discharge side reduces heat transfer, further improving efficiency.

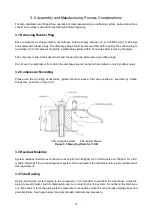

The Figure 1-3 below describes the scroll compression process:

First orbit; SUCTION gas enters at the perimeter of the scroll elements and is sealed as the scrolls rotate

approximately one revolution.

Second orbit; During the COMPRESSION process, the gas is further compressed towards the center of the

scroll elements to an intermediate pressure.

Third orbit; In the DISCHARGE orbit, the gas is further compressed to discharge pressure and then exits at

the center through the discharge port.

With a three step simultaneous process of suction, compression and discharge and two gas pockets in each

step that are 180 degrees apart, the compression process is balanced and very smooth, resulting in high

efficiency, low sound/vibration and excellent reliability.

First Orbit: SUCTION

Second Orbit: COMPRESSION

Third Orbit: DISCHARGE

Figure 1-3