42

© Panasonic Industrial Devices SUNX Co., Ltd. 2012 MJEC-SF4B01V2 No.0027-44V

English

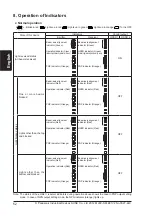

5. Mounting

CAUTION

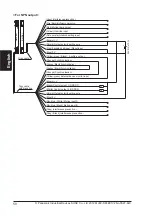

! For selecting the appropriate mounting bracket matched to the installation environment,

the mounting bracket is not incorporated in this device. Please purchase the optional

]j ]j[]

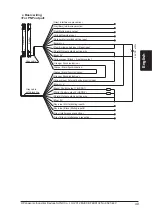

! Do not apply the load such as forced bending to the cable of this device. Applying im-

proper load could cause the wire breakage.

! The minimum bending radius of the cable

SFB-

]]*[-

ing the cable bending radius.

WARNING

When this device is used as a safety equipment for press machines or shears (paper

shears) in Japan, be sure to use the cable with protective tube

SFPB-

_ `>

minimum bending radius of the

SFPB-

]] _[ `

Mount the sensor considering the cable bending radius.

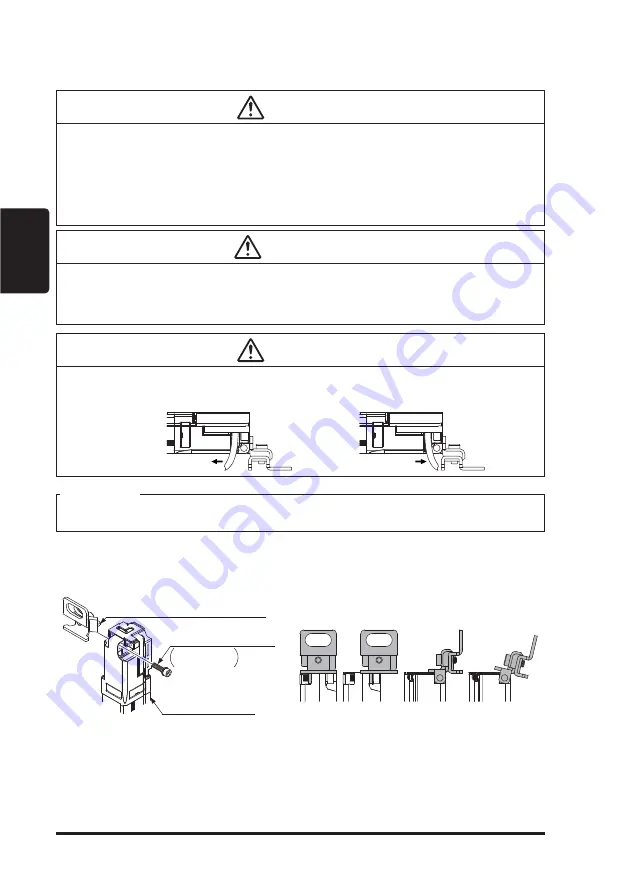

CAUTION

In case mounting the mounting bracket after mounting the bottom cap cable and the series

connection cable, be sure drawing the cable to other side of the hexagon-socket head bolt

to prevent the cable from press by the bolt.

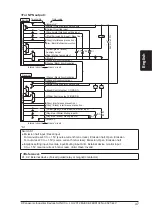

Mount the emitter and the receiver at the same level and parallel to each other. The effective aperture

angle of this device is ±2.5° or less at a sensing distance of 3m.

/&+!$+ ;=#! ?&';@Y! !Z[

1. Set the device with its mounting hole on the side just overlapping with the mounting hole of

* ]j } * ]j { = -

gon-socket head bolt [M5 (length: 18mm)]. The tightening torque should be 1.2N·m or less.

<Reference>

Good

Not good

This device (Rear side)

M8 Rear mounting bracket

MS-SFB-7-T

(Optional)

Hexagon-socket head bolt

[M5 (length: 18mm)]

Enclosed with

MS-SFB-7-T

Good Not good Good

Not good