<Conditions: Line synchronization, Test input function invalid, Interlock function invalid>

●

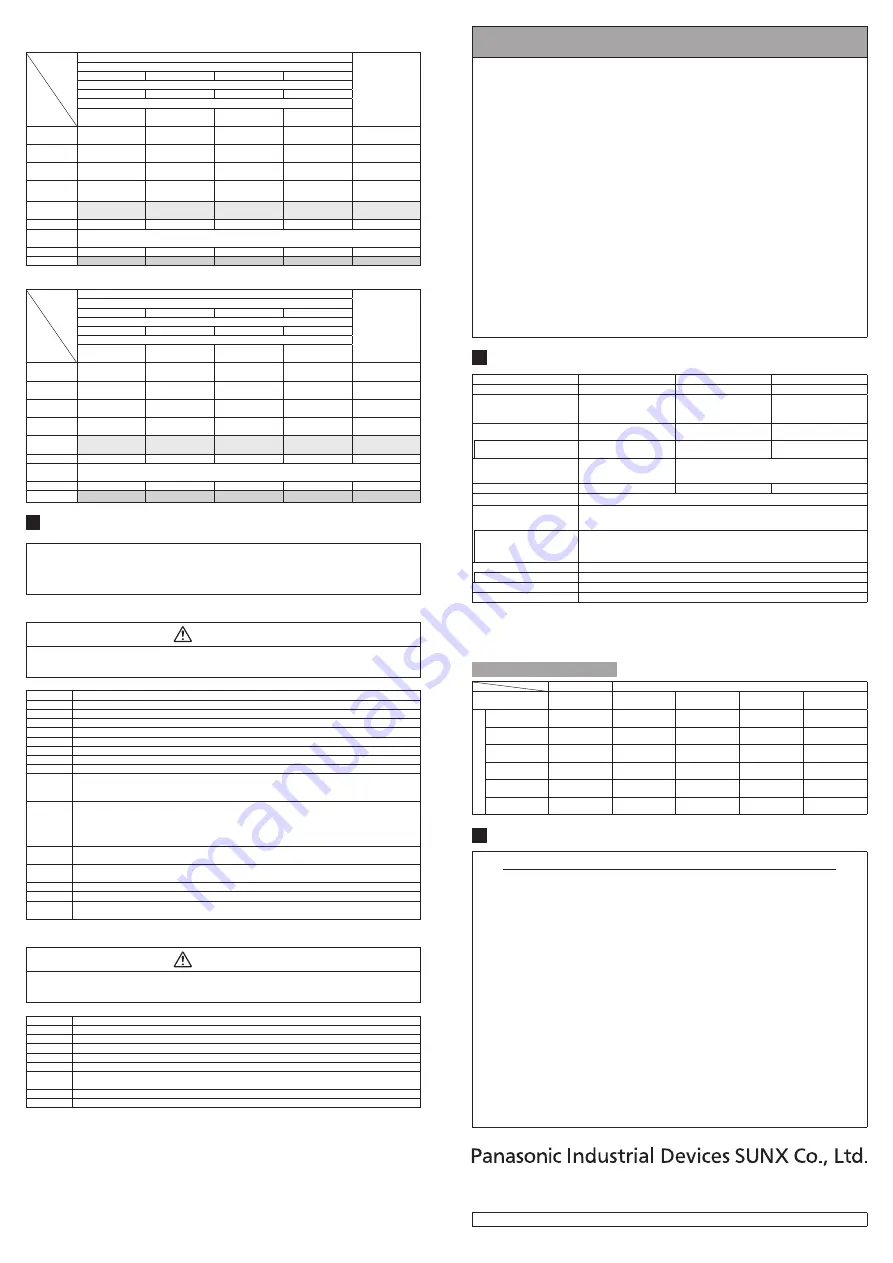

Emitter indicator operation when error occurs

Light blocked state

Light received state

(all beam channels)

Top end beam channel

Light blocked

Light received

Light blocked

Light received

Bottom end beam channel

Light blocked

Light blocked

Light received

Light received

Other beam channels

Light received /

Light blocked

Light received /

Light blocked

Light received /

Light blocked

Light blocked

Control output

(OSSD 1 / 2)

OFF

OFF

OFF

OFF

OFF

Upper application

indicator

Turns OFF

Turns OFF

Turns OFF

Turns OFF

Turns OFF

Lower application

indicator

Turns OFF

Turns OFF

Turns OFF

Turns OFF

Turns OFF

Stable light

reception indicator

Turns OFF

Turns OFF

Turns OFF

Turns OFF

Turns OFF

Digital indicator Blinking or lights

yellow number

Blinking or lights

yellow number

Blinking or lights

yellow number

Blinking or lights

yellow number

Blinking or lights

yellow number

Frequency indicator

Turns OFF

Turns OFF

Turns OFF

Turns OFF

Turns OFF

Light emission intensity

control indicator

When short mode is selected by DIP switch: Lights orange

Test indicator

Turns OFF

Turns OFF

Turns OFF

Turns OFF

Turns OFF

Operation indicator

Lights red

Lights red

Lights red

Lights red

Lights red

●

Receiver indicator operation when error occurs

Light blocked state

Light received state

(all beam channels)

Top end beam channel

Light blocked

Light received

Light blocked

Light received

Bottom end beam channel

Light blocked

Light blocked

Light received

Light received

Other beam channels

Light received /

Light blocked

Light received /

Light blocked

Light received /

Light blocked

Light blocked

Control output

(OSSD 1 / 2)

OFF

OFF

OFF

OFF

OFF

Upper application

indicator

Turns OFF

Turns OFF

Turns OFF

Turns OFF

Turns OFF

Lower application

indicator

Turns OFF

Turns OFF

Turns OFF

Turns OFF

Turns OFF

Stable light

reception indicator

Turns OFF

Turns OFF

Turns OFF

Turns OFF

Turns OFF

Digital indicator Blinking or lights

yellow number

Blinking or lights

yellow number

Blinking or lights

yellow number

Blinking or lights

yellow number

Blinking or lights

yellow number

Frequency indicator

Turns OFF

Turns OFF

Turns OFF

Turns OFF

Turns OFF

Function setting

indicator

When the blanking function or parallel connection is used: Lights yellow (Applicable model:

SF4D-□

)

When the communication module

SF4D-TM1

(option) is connected: Blinks orange

Interlock indicator

Turns OFF

Turns OFF

Turns OFF

Turns OFF

Turns OFF

OSSD indicator

Lights red

Lights red

Lights red

Lights red

Lights red

10

MAINTENANCE

<Reference>

If you notice an abnormal condition, refer “

our web site:

https://panasonic.net/id/pidsx/global

”.

If you are unsure what action to take, contact our office.

Make a copy of the checklist, enter a checkmark after checking each item, and retain the list.

●

Daily inspection

WARNING

Before starting work, inspect the items below and verify that there are no abnormalities. Risk of death

or serious injury if inspection is neglected or the device is operated with an abnormal condition.

Check column

Inspection item

□

Dangerous parts of the machine cannot be reached without passing through the sensing area of the device.

□

Some part of the operator’s body remains in the sensing area when working with dangerous parts of the machine.

□

The device is installed at a distance that is equal to or greater than the calculated safety distance.

□

No safety guard or protective structure damage.

□

No damaged, defective, or bent wires.

□

All connectors are firmly connected.

□

No dirt or scratches on the light emitting surface.

□

Test rods are not deformed or defective.

□

When no objects are present in the sensing area, the operation indicator (green) of the emitter and the

OSSD indicator (green) of the receiver are lit. The control output (OSSD 1 / 2) is ON. You can check for

effects of external noise in this state. If external noise affects operation, remove the cause and reinspect.

□

When moved at a speed of 1,600mm/sec or less, it should be possible to detect the test rod [ø14mm

for

SF4D-F

□(

-01

), ø25mm for

SF4D-H

□(

-01

),, ø45mm for

SF4D-A

□(

-01

),] directly in front of the emit-

ter, midway between the emitter and the receiver, and directly in front of the receiver (3 positions).

When the test rod is in the sensing area, the OSSD indicator (red) of the receiver and the operation in-

dicator (red) of the emitter remain lit.

□

When the machine is in the operating state, dangerous parts operate normally (do not stop) when no

objects are present in the sensing area.

□

When the machine is in the operating state, dangerous parts stop immediately when the test rod is inserted directly

in front of the emitter, midway between the emitter and the receiver, and directly in front of the receiver (3 positions).

□

Dangerous parts remain stopped as long as the test rod is present in the sensing area.

□

Dangerous parts stop immediately when the power of the device is turned OFF.

□

Be sure to test operation before using the muting function. Check the condition of the muting indicator

(dirt, brightness, etc.).

●

Periodic inspection (every six months)

WARNING

Be sure to inspect the following items every six months and verify that there are no abnormalities. Risk

of death or serious injury if inspection is neglected or the device is operated with an abnormal condition.

Check column

Inspection item

□

The structure of the machine does not obstruct any safety mechanisms for stopping operation.

□

No modification has been made in the machine control system that obstructs the safety mechanisms.

□

Output from the device is correctly detected.

□

Wiring from the device is correct.

□

The response time of the overall system is equal to or less than the calculated value.

□

The current number of operation cycles (time) of parts with a limited service life is less than the num-

ber of service life cycles (time).

□

No screws or connectors related to the device are loose.

□

No objects that scatter or reflect light have been added near the device.

●

Inspection after maintenance

1.

When any parts of the device are replaced.

2.

When an abnormal condition is noticed during operation.

3.

After aligning the beam axes of the emitter and receiver.

4.

When the installation site or environment of the device is changed.

5.

When the wiring method or wiring layout is changed.

6.

When a safety relay unit or external device (forcible guide relay or magnetic con-

tactor) part has been replaced.

7.

When safety controller or safety PLC settings are changed.

When using as a safety device for a press machine in Japan

(Applicable model: SF4D-□-01)

When using as a safety device for a press machine in Japan, press machine work

supervisors and personnel in charge of the matters described in No. 1, No. 2, and

No. 4 of Article 134 of the Occupational Safety and Health Act are required to per-

form inspection prior to the start of work and perform periodic inspection.

Press machine work supervisors, etc. must inspect the items below prior to the

start of work and record/retain the results.

Device emitter

●

Firmness of installation

●

Suitability of installation position

(safe distance and vertical position)

●

Existence of damage

●

Existence of external wire abnormal-

ities

●

Existence of dirt on emitter

●

Certainty of detection states

Device receiver

●

Firmness of installation

●

Suitability of installation position

(safe distance and vertical position)

●

Existence of damage

●

Existence of external wire abnormal-

ities

●

Existence of dirt on emitter

●

Certainty of detection states

Specified control unit

SF-C11

,

SF-C13

●

External wiring

●

Indicator

●

Abnormal operation of switches, etc.

●

Firmness of installation

For details, refer to "Press Machine Safety Device Control Policy" of the Ministry of

Health, Labour and Welfare.

11

SPECIFICATIONS

Type

10mm pitch type

20mm pitch type

40mm pitch type

Model No.

SF4D-F

□(

-01

)

SF4D-H

□(

-01

)

SF4D-A

□(

-01

)

Number of beam channels

15/23/31/39/47/55/63/71/

79/95/111/127

8/12/16/20/24/28/32/36/40

/48/56/64/72/80/88/96

4/6/8/10/12/14/16/18/20/

24/28/32/36/40/44/48

Detection width

(protection height)

150 (15 beam channels) to

1,270mm (127 beam channels)

150 (8 beam channels) to

1,910mm (96 beam channels)

150 (4 beam channels) to

1,910mm (48 beam channels)

When using as safety equipment for

press machines in Japan and China

140 (15 beam channels) to

1,260mm (127 beam channels)

140 (8 beam channels) to

1,900mm (96 beam channels)

120 (4 beam channels) to

1,880mm (48 beam channels)

Sensing range (effective)

Short mode: 0.2 to 7m

Long mode: 0.8 to 12m

(selectable by DIP switch)

Short mode: 0.2 to 9m, Long mode: 0.8 to 15m

(selectable by DIP switch)

Minimum sensing object

ø14mm opaque object

ø25mm opaque object

ø45mm opaque object

Supply voltage

24V DC

+20

-30

% (excluding voltage drop due to cable)

Control output (OSSD 1 / 2)

Maximum source (PNP) / sink (NPN) current: 350mA, Residual voltage: 2V or less

Leakage current: 0.2mA or less, Maximum load capacity: 2.2μF

Load wiring resistance: 3Ω or less

Response time

OFF response: 10ms or less (not connected in serial / parallel)

18ms or less (connected in serial / parallel)

(Refer to

<Response time by number of beam channels (OFF response)>

)

ON response: 50ms or less (Note 1, 2)

Auxiliary output (AUX)

Maximum source (PNP) / sink (NPN) current: 60mA, residual voltage: 2V or less

Response time

OFF response: 60ms or less, ON response: 60ms or less

Ambient temperature

−10 to +55°C, Storage: −25 to +60°C

Ambient humidity

30 to 85% RH, storage: 30 to 95% RH

Notes: 1) Because the control output (OSSD 1 / 2) must be OFF for at least 80ms, the ON response will be delayed

more than 50ms when the light blocked time is less than 30ms.

2) When optical synchronization is selected, if the beam axes of both the top end and bottom end are blocked,

the ON response speed decreases by as much as 1 sec.

<Response time by number of beam channels (OFF response)>

Control output (OSSD 1 / 2)

Main sensor

Sub sensor

Number of units in

series connection

1 unit

1 unit

2 units

3 units

4 units

Number of beam channels

4 to 48 beam

channels

6ms

10ms

10ms

12ms

12ms

49 to 96 beam

channels

8ms

10ms

10ms

12ms

12ms

97 to 127 beam

channels

10ms

12ms

12ms

14ms

14ms

128 to 144 beam

channels

−

12ms

12ms

14ms

14ms

145 to 192 beam

channels

−

14ms

14ms

16ms

16ms

193 to 256 beam

channels

−

16ms

16ms

18ms

18ms

12

CE MARKING DECLARATION OF CONFORMITY

Itemized Essentials of EU Declaration of Conformity

Manufacturer’s Name:

Panasonic Industrial Devices SUNX Co., Ltd

Manufacturer’s Address:

2431-1, Ushiyama-cho, Kasugai, Aichi 486-0901, Japan

EU Representative’s Name:

Panasonic Marketing Europe GmbH Panasonic Testing Center

EU Representative’s Address:

Winsbergring 15, 22525 Hamburg,Germany

Product:

Active Opto-electronic Protective Device (Light Curtain)

Model Name: SF4D

Series

Trade Name:

Panasonic

Application of Council Directive:

- 2006/42/EC Machinery Directive

- 2014/30/EU EMC Directive

- 2011/65/EU RoHS Directive

Harmonized standards:

- EN 61496-1

- EN ISO 13849-1

- EN 55011

- EN 61000-6-2

- EN 50581

Type Examination:

Certified by TÜV SÜD Product Service GmbH Ridlerstrasse

65 80339 München Germany

https://panasonic.net/id/pidsx/global

Overseas Sales Division (Head Office)

2431-1 Ushiyama-cho, Kasugai-shi, Aichi, 486-0901, Japan

Phone: +81-568-33-7861 FAX: +81-568-33-8591

For sales network, please visit our website.

PRINTED IN JAPAN

© Panasonic Industrial Devices SUNX Co., Ltd. 2018