Maintenance

© Panasonic Industrial Devices SUNX Co., Ltd. 2017

128

<Reference>

If you discover an abnormal condition, refer to

and inform your technician.

If you are unsure what action to take, contact our office.

Make a copy of the checklist, enter a checkmark after checking each item, and retain the list.

4-1 Daily Inspection

WARNING

Before starting work, inspect the items below and verify that there are no abnormalities. Risk of death

or serious injury if inspection is neglected or the device is operated with an abnormal condition.

Checklist (daily inspection)

Check column

Inspection item

□

Dangerous parts of the machine cannot be reached without passing through the sensing area of the device.

□

Some part of the operator’s body remains in the sensing area when working with dangerous parts of the machine.

□

The device is installed at a distance that is equal to or greater than the calculated safety distance.

□

No safety guard or protective structure damage.

□

No damaged, defective, or bent wires.

□

All connectors are firmly connected.

□

No dirt or scratches on the light emitting surface.

□

Test rods are not deformed or defective.

□

When no objects are present in the sensing area, the operation indicator (green) of the emitter and the

OSSD indicator (green) of the receiver are lit. The control output (OSSD 1 / 2) is ON. You can check for

effects of external noise in this state. If external noise affects operation, remove the cause and reinspect.

□

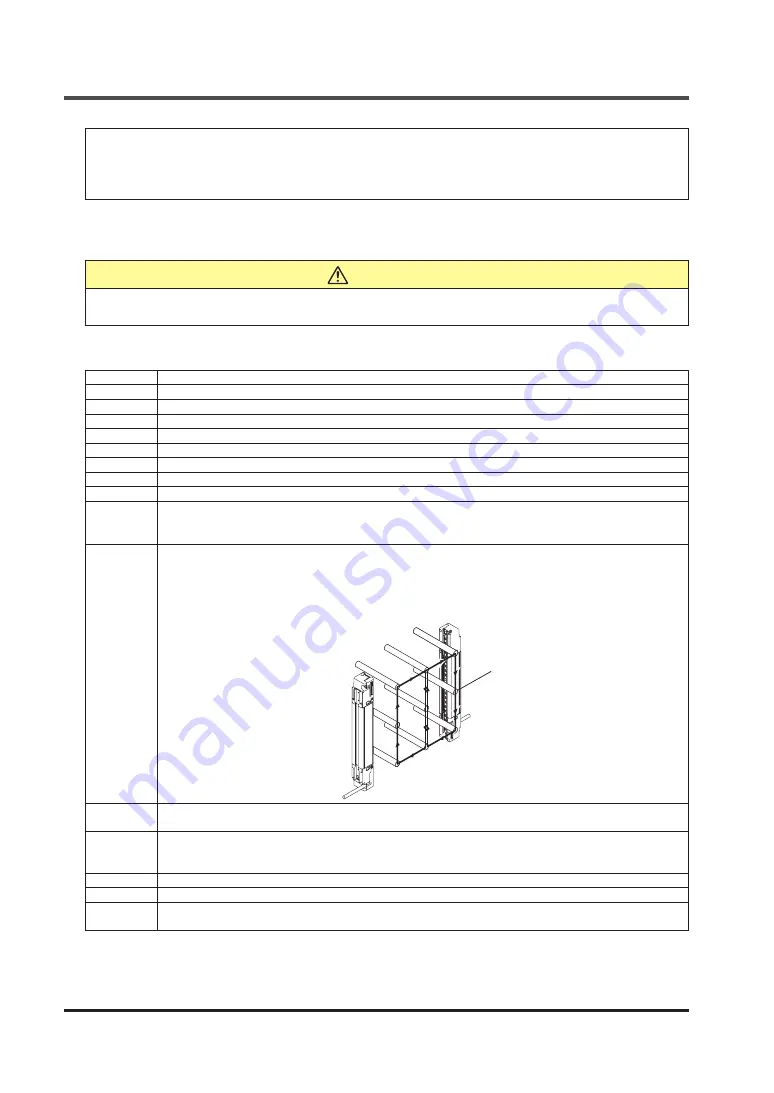

When moved at a speed of 1,600mm/sec. or less, it should be possible to detect the test rod

(ø14mm for

SF4D-F

□, ø25mm for

SF4D-H

□, ø45mm for

SF4D-A

□) directly in front of the emitter

(A), midway between the emitter and the receiver (B), and directly in front of the receiver (C) (3

positions). When the test rod is in the sensing area (A) to (C), the OSSD indicator (red) of the re

-

ceiver and the operation indicator (red) of the emitter remain lit.

Test rod

(A)

(B)

(C)

Emitter

Receiver

□

When the machine is in the operating state, dangerous parts operate normally (do not stop) when

no objects are present in the sensing area.

□

When the machine is in the operating state, dangerous parts stop immediately when the test rod

is inserted directly in front of the emitter (A), midway between the emitter and the receiver (B), and

directly in front of the receiver (C) (3 positions).

□

Dangerous parts remain stopped as long as the test rod is present in the sensing area.

□

Dangerous parts stop immediately when the power of the device is turned OFF.

□

Be sure to test operation before using the muting function. Check the condition of the muting indi-

cator (dirt, brightness, etc.).

Summary of Contents for SF4D-x-01 Series

Page 2: ... Panasonic Industrial Devices SUNX Co Ltd 2017 2 MEMO ...

Page 126: ...Functions Panasonic Industrial Devices SUNX Co Ltd 2017 126 MEMO ...

Page 130: ...Maintenance Panasonic Industrial Devices SUNX Co Ltd 2017 130 MEMO ...

Page 140: ...Troubleshooting Panasonic Industrial Devices SUNX Co Ltd 2017 140 MEMO ...

Page 174: ... Panasonic Industrial Devices SUNX Co Ltd 2017 174 MEMO ...