Adjustment for White Balance

Preparation :

1. Receive the white balance pattern and aging should have been performed over 30 minutes.

2. Set the picture menu to to DYNAMIC NORMAL.

3. Degause the CRT face.

4. Fix the CRT colour analyzer receiver unit to CRT face.

Adjustment of Low Light.

1. Adjustment Sub Bright, so that Y = 6.3 +- 1.0nit.

2. Adjust R-CUT OFF, so that X = 0.235 +- 0.01nit.

3. Adjust G-CUT OFF, so that y = 0.235 +- 0.01nit.

Adjustment of High Light.

1. Adjust Sub Bright, so that Y = 390 nit.

2. Adjust R-Drive, so that X = 0.259 +- 0.01nit.

3. Adjust B-Drive, so that y = 0.259 +- 0.01nit.

Adjustment for CRT CUT OFF.

Preparation :

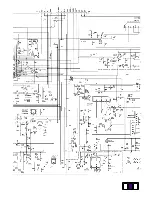

1. Connect ocilloscope probe to TPL7.

2. Screen VR min.

3. Set the data Sub Bright , Bright.

4. In service Mode at ‘Bright’ dac press [5] in factory mode to enter vertical line and adjust by

volume down or up button.

5. Adjust “Screen VR” until 1-H Line appears.

130V

0V