4.1.1. +B Voltage

Item / preparation

1. Operate the TV set.

2. Set control as follows :

Brightness ........... minimum

Contrast .............. minimum

Adjustment Procedure

1. Confirm the DC voltage at the indicated test points, as

follows:

TPD 15 : 3.3 ± 0.2V

TPD 16 : 141 ± 2V

TPD 17 : 8 ± 2V

TPD 18 : 1.8 ± 2V

TPD 19 : 5 ± 2V

TPD 20 : 220 ± 2V

4.1.2. RF AGC

Item / preparation

1. Receive a colour bar signal at an RF level of 69 ±2 dBU

with 75

Ω

loaded.

2. Connect digital multimeter to RF AGC at Tuner.

Adjustment Procedure

1. Select “RF AGC” indication in CHK2, on Screen by

remote control at factory mode.

2. Set RF AGC by using remote control Volume (+) or

Volume (-) button until voltage AGC at Tuner reaches

0.2V at TPD 30 (Tuner point).

3. Increase RF signal strength by 2dB, confirm AGC at

Tuner voltage drop.

1. Set Bright and Contrast controls to their maximum

positions.

2. Operate the TV set over 60 minutes.

3. Full degauss the picture tube by using an external

degaussing coil. By rotating R-B static convergence

magnet.

4. Apply a crosshatch pattern signal and adjust roughly the

static convergence magnets.

5. Apply a green pattern signal.

4.1.3. High Voltage

Item / preparation

1. Receive the crosshatch pattern.

2. Set to 0 Beam.

Screen VR .......... minimum

Contrast .............. minimum

Adjustment Procedure

1. Connect a DC voltage meter to D866 and confirm the

+B voltage is 141.0 ± 1.5V.

2. Connect a high frequency voltmeter to heater and

confirm that voltage reads 6.3 ± 0.28 (VRMS).

3. Normalize the brightness and contrast.

4.1.4. NTSC TINT COLOUR

Item / Preparation

1. Connect oscilloscope probe to TPL1 (R OUT) with 10k

Ω

series resistor.

2. Press Main Menu and set system to use AV-NTSC

(3.58 MHz)

DYNAMIC ................. Normal

Channel CLR Set ..... STD

Adjustment Procedure

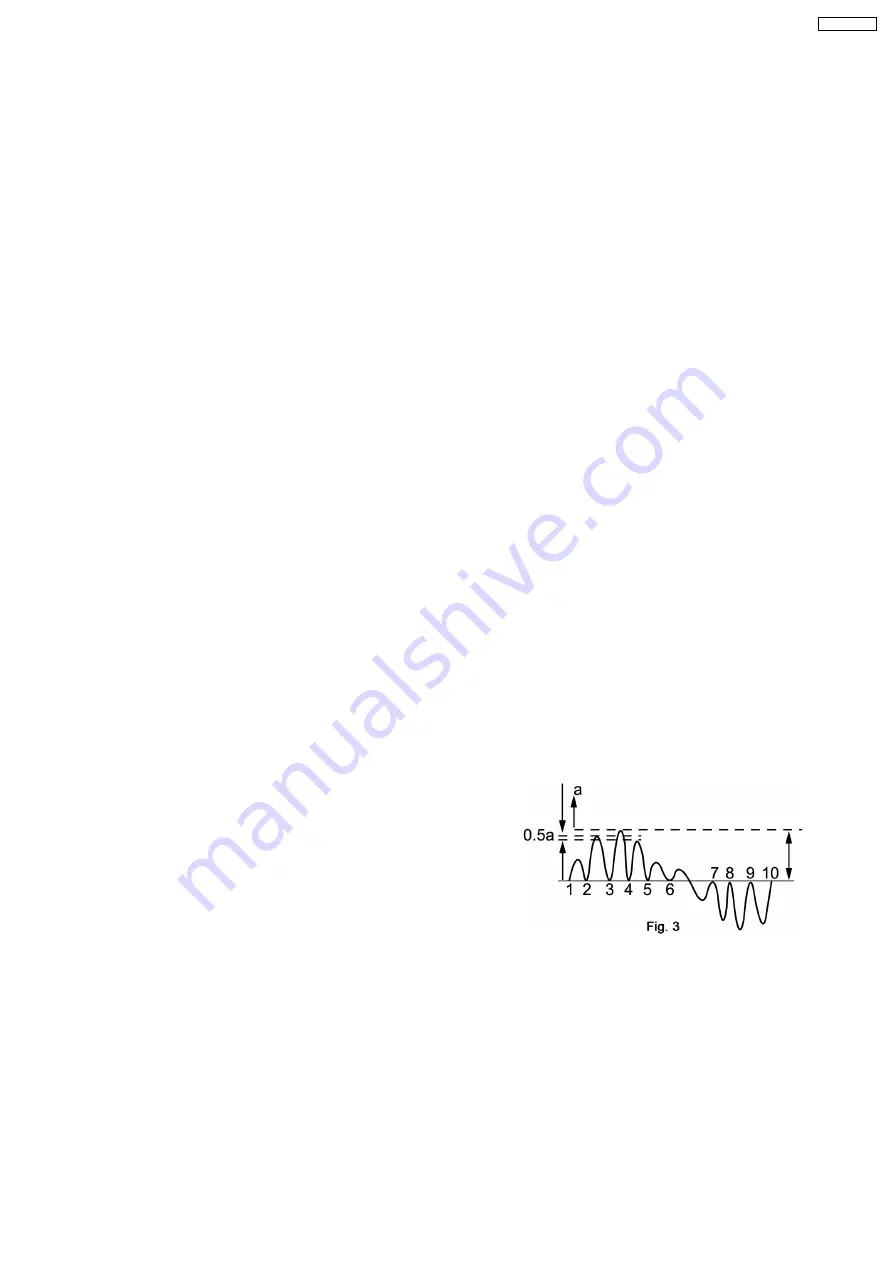

1. Adjust Sub-Tint so that No. 2, 3 and 4 becomes level

waveform is similar to Fig. 3.

2. Confirm phase at Tint is changes more than ± 15 by Tint

control.

3. Confirm that colour level is maximum when colour DAC

is adjusted to maximum position.

Note:

Use remote control only when adjusting user

mode to Sub-Tint.

6. Loosen a clamp screw for the Deflection Yoke and move

the Deflection Yoke as close to the purity magnet as

possible.

7. Adjust the purity magnet so that a vertical green field is

obtained at the center of the screen.

4 Adjustment Procedure

4.1. Adjustment Procedure

4.2. COLOUR PURITY

7

TC-25FG50H

Summary of Contents for TC-25FG50H

Page 11: ...5 Conductor Views 5 1 D Board 1 2 11 TC 25FG50H...

Page 12: ...5 2 D Board 2 2 12 TC 25FG50H...

Page 13: ...6 Schematic Diagrams 6 1 SCHEMATIC DIAGRAM FOR GP4 CHASSIS 13 TC 25FG50H...

Page 14: ...14 TC 25FG50H...

Page 15: ...6 2 D Board 6 2 1 D Board 1 5 1A 2A 3A 4A 5A 6A 7A 8A 15 TC 25FG50H...

Page 16: ...6 2 2 D Board 2 5 1A 2A 3A 4A 5A 6A 7A 8A 1B 2B 3B 4B 5B 6B 7B 8B 16 TC 25FG50H...

Page 17: ...6 2 3 D Board 3 5 1B 2B 3B 4B 5B 6B 7B 8B 1C 2C 3C 4C 5C 6C 7C 17 TC 25FG50H...

Page 18: ...6 2 4 D Board 4 5 1C 2C 3C 4C 5C 6C 7C 1D 2D 3D 4D 5D 6D 7D 18 TC 25FG50H...

Page 19: ...6 2 5 D Board 5 5 1D 2D 3D 4D 5D 6D 7D 19 TC 25FG50H...

Page 20: ...6 3 G Board 6 3 1 G Board 1 3 1A 2A 3A 4A 5A 20 TC 25FG50H...

Page 21: ...6 3 2 G Board 2 3 1A 2A 3A 4A 5A 1B 2B 3B 4B 5B 21 TC 25FG50H...

Page 22: ...6 3 3 G Board 3 3 1B 2B 3B 4B 5B 22 TC 25FG50H...

Page 23: ...6 4 L Board 6 4 1 L Board 1 3 1A 2A 3A 4A 5A 6A 23 TC 25FG50H...

Page 24: ...6 4 2 L Board 2 3 1A 2A 3A 4A 5A 6A 1B 2B 3B 4B 5B 6B 24 TC 25FG50H...

Page 25: ...6 4 3 L Board 3 3 1B 2B 3B 4B 5B 6B 25 TC 25FG50H...

Page 26: ...7 Parts Locations 26 TC 25FG50H...

Page 27: ...8 1 Replacement Parts List Notes 8 Replacement Parts List 27 TC 25FG50H...