ー 28 ー

ー 29 ー

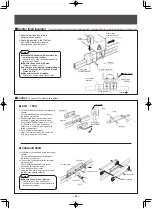

■

Spacer

To straighten twists in the Tro-Reel unit.

■

Sheath repair cover

Insert a flat tip screwdriver between the

clip and the Tro-Reel and pry down with

the screwdriver.

●

How to remove a spacer

●

How to install a spacer

1. Loosen clip screws and align B

with the Tro-Reel unit installation

intervals.

2. Snap the clips to the Tro-Reel

units.

3. Make sure the screws are

tightened securely. Failure to do

so may cause damage due to

falling of equipment.

Clip

Screw

B

Attachment

Tro-Reel unit

Interval between

units

B

B

Screwdriver

Attachment

Tro-Reel

Clip

Nut

Cover

Cover screw

Tro-Reel unit

80mm

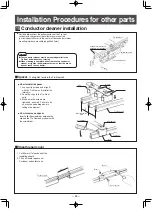

Conductor cleaner installation

●

Set the distance from the bottom surface of the Tro-reel

conductor to the center of the collector arm mount rod

(not included) to 95mm (in the center of the conductor clerner

mounting tolerance movable range 95±20mm)

Tro-Reel unit

Adjustment screw

95±20

Conductor cleaner

25×25mm

Collector arm mount rod,

25×25mm (not included)

●

The conductor cleaner must be mounted parallel to the

Tro-Reel unit without any twisting.

●

When cleaning is complete, either remove the conductor

cleaner, or tighten the adjustment screw so that the brush

doesn’t touch the conductor.

Notes

10

Installation Procedures for other parts

(Permitted movable range)

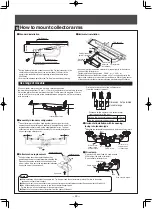

1. Cut 80mm off of each end of the

insulating sheath.

2. Fit on a Sheath repair cover .

For indoor and outdoor use.

●

When power is to be fed from the joint of Tro-Reel units, cut 40mm off of each end of

the insulating sheath and connect them to the terminal plates. Drill a φ5mm hole in

the conductor and insert a knock pin through the hole.

Failure to do so may cause

damage due to falling of equipment.

The terminal screws must be securely tightened.

(

tightening torque 6.9

〜

7.9N

・

m

)

Failure to do so may cause fire.

●

Be sure to use a file of φ5 size.

●

The φ5mm knock pins must be securely fitted.

Failure to do so may cause damage due to falling of equipment.

■

Center feed-in joiner

To feed power from an intermediate point on a line or from a joint between Tro-Reel units.

150

〜

200mm

Center feed-in joiner

200

〜

1000mm

Hanger support point

Center feed-in joiner

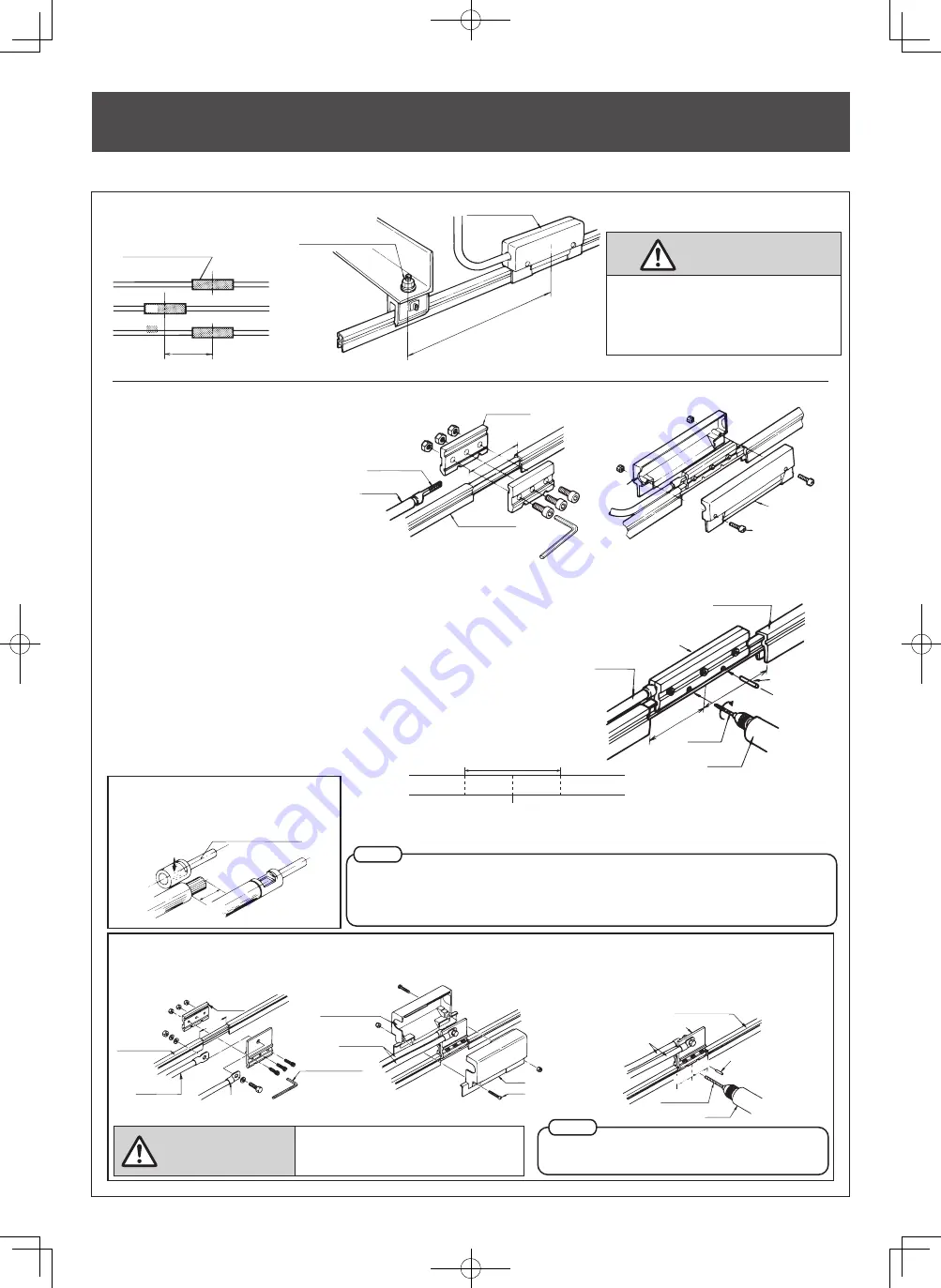

< 300A > (applicable wire of 150mm

2

or less, or 100mm

2

×

2)

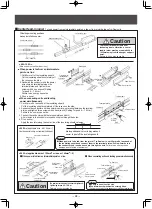

1. Cut 80mm off of the insulating sheath.

Cut the insulating sheath completely off

the recess on the side.

2. Sandwich the conductor and the power

wire crimp-on terminal between the

terminal plates, and tighten three

screws with a hex wrench [ Setting

Torque 6.9

〜

7.9N

・

m].

Failure to do so may cause fire.

3. Fit on a cover.

1. Cut 40mm off of each end of the insulating sheath.

Cut the insulating sheath completely off the recess on the side.

2. Sandwich the conductor and the power wire crimp-on terminal between the terminal

plates, and tighten three screws with a hex wrench [ Setting Torque 6.9

〜

7.9N

・

m].

Failure to do so may cause fire.

3. Connect the conductors with the terminal plates and drill

φ5mm boles in the conductors.Insert knock pins through the holes.

4. Fit on a cover.

Apply the insulator along the center line of the insulating sheath cutaway.

●

When power is fed from an intermediate

point on a line

■

When connecting units and feeding power simultaneously

●

When connecting units and feeding

power simultaneously

Terminal plate

Crimp-on terminal

(Accompanying)

Power wire

Tro-Reel unit

80m

m

hex wrenc

h

(not included)

Drill a knockout

hole here.

Feed-in cover

Cover screw

Tro-Reel unit

Terminal plate

Power wire

φ

5mm

drill bit

Drill

φ

5mm knock pin

40mm

40m

m

< 200A >

(applicable wire: 60-100mm

2

)

Use the special crimp-on terminal (included).

Special crimp-on terminal for 200A

Crimp here

23

〜

25mm

80mm

Making additional cuts midway makes it

easier to peel off the insulating sheath.

Terminal plate

Tro-Reel unit

Power wire

Crimp-on terminal (not included)

Terminal screw

(

M12

)

Hex key wrench

(not included)

Drill a knockout

hole here.

Power wire

Feed-in cover

Cover screw

80mm

Terminal plate

Power wire

φ

5mm knock pin

φ

5mm drill bit

Drill

40mm

40mm

Tro-Reel unit

Offsetting mounting positions

makes installation easier.

Caution

To prevent terminal screws from

loosening due to vibration, a center

feed-in joiner must be mounted 200 to

1000mm away from the hanger support

point.

Failure to do so may cause fire.

Caution

Notes

Notes

< 60A

・

150A >

(Wire units must be 50mm

2

or less)

■

When power is fed from an intermediate point on a line.