ー 24 ー

ー 25 ー

●

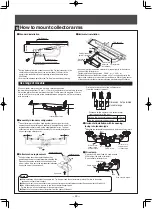

Use a tandem-type collector

arm and set the traveling

speed for switching sections

to 60m/min. or less.

●

Be sure to use only the

specified dimensions for each

mounting part.

Failure to do so may cause poor

collector arm

contact or

separation from wires.

●

In the case using at outdoors,

Please contact Pansonic

Electric Works Co.,Ltd.

●

Mount the cover by all means.

Failure to do so may cause

electric shock.

■

Guide cap

To guide collector arms via turntables or traversers.

■

Insulating piece

To Separate circuits electrically.

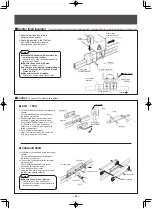

Type

Hanger bracket

Bracket for retaining tension

Angle dimensions

for 3P

-40

×

40

×

5

100

×

50

×

5

A size

250

〜

300mm

B size

Minimum

Standard

75mm

100mm

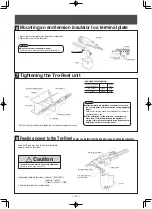

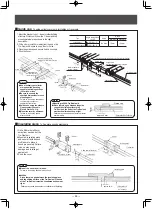

<Mounting to 300A Tro-Reel unit>

●

Since there is a gap between the guide

cap and the sliding surface to the

Tro-Reel unit, the end of the Tro-Reel unit

must be chamfered as shown right.

Failure may cause bad contact or collector

arm derailing.

1. Mount the bracket to an

Ⅰ

-beam or other building

structure. Distances (A) from the

Ⅰ

-beam and the

mounting interval are as shown in the right

description.

2. Drill a

φ

5mm hole 20mm away from the end of

the

Tro-Reel unit.

Be sure to use a file of

φ

5 size.

3. Place the guide cap and secure it with a knock pin.

4. Fit on the cover.

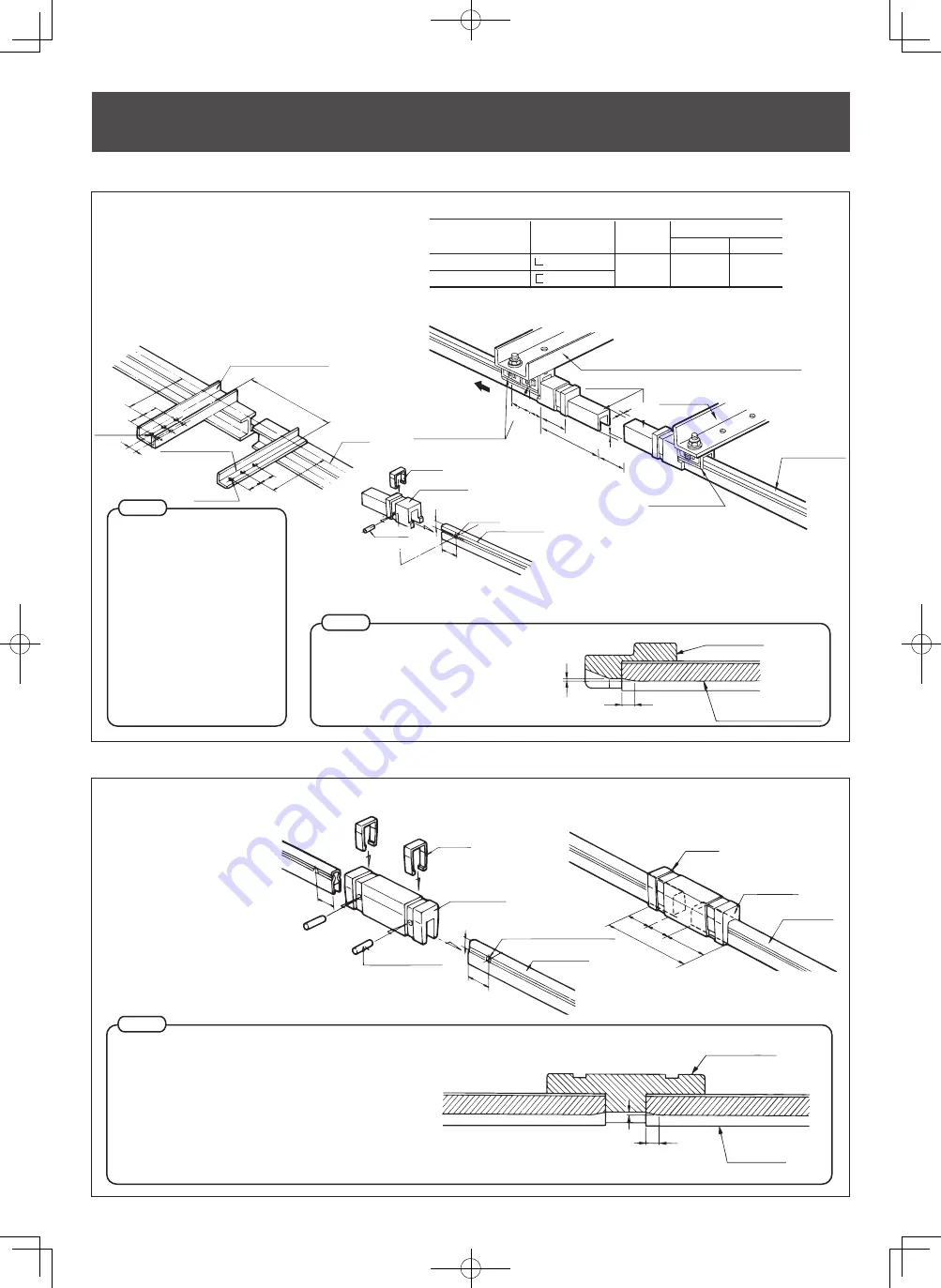

1.Drill a Φ5mm hole 20mm

away from each end of the

Tro-Reel unit

2.Mount an insulating piece

and secure it with a knock

pin.Be sure to place a

knock pin securely. Failure

to do so may cause

damage due to falling of

equipment.

3.Fit on the cover.

approx.5mm

2m

m

Sliding surface of the Tro-Reel unit

Guide cap

20mm

20m

m

7m

m

Cover

Knock pin (

φ

5

×

18mm)

φ

5mm hole (for knock pin)

Tro-Reel unit

Insulating piece

45mm

120m

m

45mm

Tro-Reel unit

Insulating piece

Cover

30mm

approx.5mm

2m

m

Insulating piece

Sliding surface of

the Tro-Reel unit

23mm

35mm

75mm

10-30mm or les

s

5mm

or less

Tensio

n

Attach two standard

hangers in parallel.

Guide cap

Bracket for retaining tension (bracket used for when tensionis applied)

Hanger bracket

(bracket used when no tension is applied)

Tro-Reel unit

Standard hanger

7mm or less

46mm

φ

11mm hole

46m

m

A

B

B

Hanger bracket

φ

11mm hole

A

B

B

(bracket used when no

tension is applied)

Bracket for retaining tension

(bracket used for when tension is applied)

240m

m

I-beam

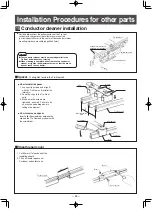

Notes

●

Mount the cover by all means.

Failure to do so may cause electric shock.

●

<300A>

Since there is a gap between the insulating piece

and the sliding surface of the Tro-Reel unit, the end

of the Tro-Reel unit must be chamfered as shown at

right.

Failure may cause bad contact or collector arm derailing.

Notes

Notes

Cover

Guide Cap

φ

5mm hole

Tro-Reel unit

20mm

knock pin

(

φ

5

×

18)

7A

I-beam

●

Use a tandem-type collector

arm and set the traveling

speed for switching sections

to 60m/min. or less.

●

Be sure to use only the

specified dimensions for each

mounting part.

Failure to do so may cause poor

collector arm

contact or

separation from wires.

●

In the case using at outdoors,

Please contact Pansonic

Electric Works Co.,Ltd.

●

Mount the cover by all means.

Failure to do so may cause

electric shock.

■

Guide cap

To guide collector arms via turntables or traversers.

■

Insulating piece

To Separate circuits electrically.

Type

Hanger bracket

Bracket for retaining tension

Angle dimensions

for 3P

-40

×

40

×

5

100

×

50

×

5

A size

250

〜

300mm

B size

Minimum

Standard

75mm

100mm

<Mounting to 300A Tro-Reel unit>

●

Since there is a gap between the guide

cap and the sliding surface to the

Tro-Reel unit, the end of the Tro-Reel unit

must be chamfered as shown right.

Failure may cause bad contact or collector

arm derailing.

1. Mount the bracket to an

Ⅰ

-beam or other building

structure. Distances (A) from the

Ⅰ

-beam and the

mounting interval are as shown in the right

description.

2. Drill a

φ

5mm hole 20mm away from the end of

the

Tro-Reel unit.

Be sure to use a file of

φ

5 size.

3. Place the guide cap and secure it with a knock pin.

4. Fit on the cover.

1.Drill a Φ5mm hole 20mm

away from each end of the

Tro-Reel unit

2.Mount an insulating piece

and secure it with a knock

pin.Be sure to place a

knock pin securely. Failure

to do so may cause

damage due to falling of

equipment.

3.Fit on the cover.

approx.5mm

2m

m

Sliding surface of the Tro-Reel unit

Guide cap

20mm

20m

m

7m

m

Cover

Knock pin (

φ

5

×

18mm)

φ

5mm hole (for knock pin)

Tro-Reel unit

Insulating piece

45mm

120m

m

45mm

Tro-Reel unit

Insulating piece

Cover

30mm

approx.5mm

2m

m

Insulating piece

Sliding surface of

the Tro-Reel unit

23mm

35mm

75mm

10-30mm or les

s

5mm

or less

Tensio

n

Attach two standard

hangers in parallel.

Guide cap

Bracket for retaining tension (bracket used for when tensionis applied)

Hanger bracket

(bracket used when no tension is applied)

Tro-Reel unit

Standard hanger

7mm or less

46mm

φ

11mm hole

46m

m

A

B

B

Hanger bracket

φ

11mm hole

A

B

B

(bracket used when no

tension is applied)

Bracket for retaining tension

(bracket used for when tension is applied)

240m

m

I-beam

Notes

●

Mount the cover by all means.

Failure to do so may cause electric shock.

●

<300A>

Since there is a gap between the insulating piece

and the sliding surface of the Tro-Reel unit, the end

of the Tro-Reel unit must be chamfered as shown at

right.

Failure may cause bad contact or collector arm derailing.

Notes

Notes

Cover

Guide Cap

φ

5mm hole

Tro-Reel unit

20mm

knock pin

(

φ

5

×

18)

7A

I-beam

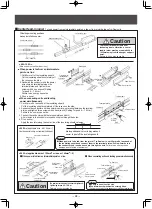

■絶縁ピース

回路を電気的に分割するときに使用します。

本体摺動面

2m

m

約5mm

絶縁ピース

本体摺動面

2m

m

約5mm

トロリール本体

絶縁ピース

カバー

120mm

45mm

45mm

30mm

カバー

(φ5×18)

トロリール本体

絶縁ピース

20m

m

7mm

φ5mm穴(ノックピン穴)

20mm

種 類

3 Pの場 合の

アングル方法

A寸法

B寸法

最小 標準

− 40×40×5

−100×50×5

250〜300mm 75mm 100mm

ハンガー用ブラケット

張力留めブラケット

■ガイドキャップ

ターンテーブル・トラバーサなどの乗り移り部分に使用します。

I

ビーム

φ11穴

A

B

B

φ11穴

A

B

B

( )

240

mm

46mm

張力をかけない時の

ブラケット

ハンガー用ブラケット

(張力をかける時のブラケット)

張力留めブラケット

以下

以下

張力

中間固定碍子

トロリール本体

標準ハンガー

中間固定碍子

標準ハンガーを

2コ並べます

( )

46mm

35mm

23mm

75mm

7m

m

5mm

10〜30mm以下

張力留めブラケット(張力をかける時のブラケット)

ハンガーブラケット

(張力をかけない時のブラケット)

ガイドキャップ

ご注意

●

集電アームはタンデム型を使用し乗り

移り部分の走行スピードは60m/分

以下とします。

●

各部の取り付け寸法を確実に守って

ください。

接触不良および、集電アームの脱線など

のおそれがあります。

●

屋外で使用の場合は、当社へお問い

合わせください。

●

カバーは必ずつけてください。

感電のおそれがあります。

ご注意

〈300Aの場合〉

●ガイドキャップと本体の摺動面の

段差がありますので、右図のよう

に本体端末を面取りしてください。

接触不良および、集電アームの

脱線などのおそれがあります。

ご注意

●

〈300Aの場合〉

ガイドキャップと本体の摺動面の段差がありますので、

右図のように本体端末を面取りしてください。接触不良

および、集電アームの脱線などのおそれがあります。

カバー

トロリール本体

ノックピン

(φ5×18)

φ5mm穴

20mm

7m

m

ガイドキャップ

1.トロリール本体の端末から

20mmのところにφ5mm

のノックピン穴をあける。

必ずφ5キリを使用する。

2.絶 縁 ピースを 取 り 付 け、

ノックピ ン で 固 定 す る 。

ノックピ ン は 確 実 に 取り

付ける。

落下のおそれがあります。

3.カバーをはめ込む。

1.ブラケットを

Ⅰ

ビームなどの造営材に取り付ける。

Ⅰ

ビームからの距離(A)および取付間隔は右表の通

りです。

2.本体の端末から20

mm

のところに、φ5

mm

のノッ

クピン穴をあける。必ずφ5キリを使用する。

3.ガイドキャップを取り付け、ノックピンで固定する。

4.カバーをはめる。

ノックピン

●

カバーは必ずつけてください。

感電のおそれがあります。

ガイドキャップ