ー 46 ー

ー 47 ー

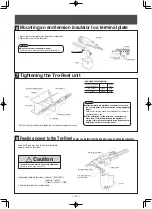

Maintenance schedule of Tro-Reel

Please check by the maintenance table based on this maintenance schedule.

Refer to the maintenance table for a concrete check item.

At introduction The 5th year

The 10th year

Maintenance done by the electrical work trader.

The product-life is different in use conditions and the service space, however, It is possible to use it for about t 10 years

by regularly maintaining and the regular service in correct construction.

・Check the presence of remarkable dirt of the surface of the conductor.

(Once every 3 to 6 months) → Clean it with the cotton waste etc.

・ Check the Tro-Reel unit doesn't become it in a zigzag line.

(Once every 3 to 6 months) →Review the size between conductors in the joint.

・Check the Tro-Reel unit is not away from the hanger.

(Once every 3 to 6 months) →Install the Tro-Reel unit on thehanger.

・Check whether there is not crack and a lack of the insulation sheath

(Once every 3 to 6 months)

→Product exchange recommendation that exchanges the Tro-Reel unit.

Tro-Reel unit

・Check the coil spring length. (Once every 3 to 6 months) →Adjust to proper length.

・Check whether there is loosening of the nut of the coil spring.

(Once every 3 to 6 months) →Retighten.

・Check whether the resin has not been damaged. (Once every 3 to 6 months)

→Exchange products.

End tension

insulator

・Check whether there is loosening of the fixation screw or the terminal screw.

(Once every 3 to 6 months) →Retighten.

・Check whether the resin has not been damaged. (Once every 3 to 6 months)

→Exchange products.

Joiner

End tension

insulator

Center fixed

insulator

Guide cap

Insulating piece

Center feed-in joiner

・Check whether there is loosening of the nut. (Once every 3 to 6 months) →Retighten.

・Check whether the resin has not been damaged. (Once every 3 to 6 months)

→Exchange products.

Hanger

・Check whether there is loosening of the bolt. (Once every 1 to

・Check whether the resin has not been damaged. (Once every 3 to 6 months)

→Exchange products

3 months) →Retighten.

・Check whether wear has reached the replacement line. (Once every 1 to 3 months)

→Exchange the collector, when worn out to the replacement line.

・Check damage of spring pin and rotation axis, wear-out of metal fittings of spring receiving.

(Once every 1 to 3 months)→Exchange products when damage or abnormality is found. Please keep normal.

Collector arm

Product exchange recommendation.

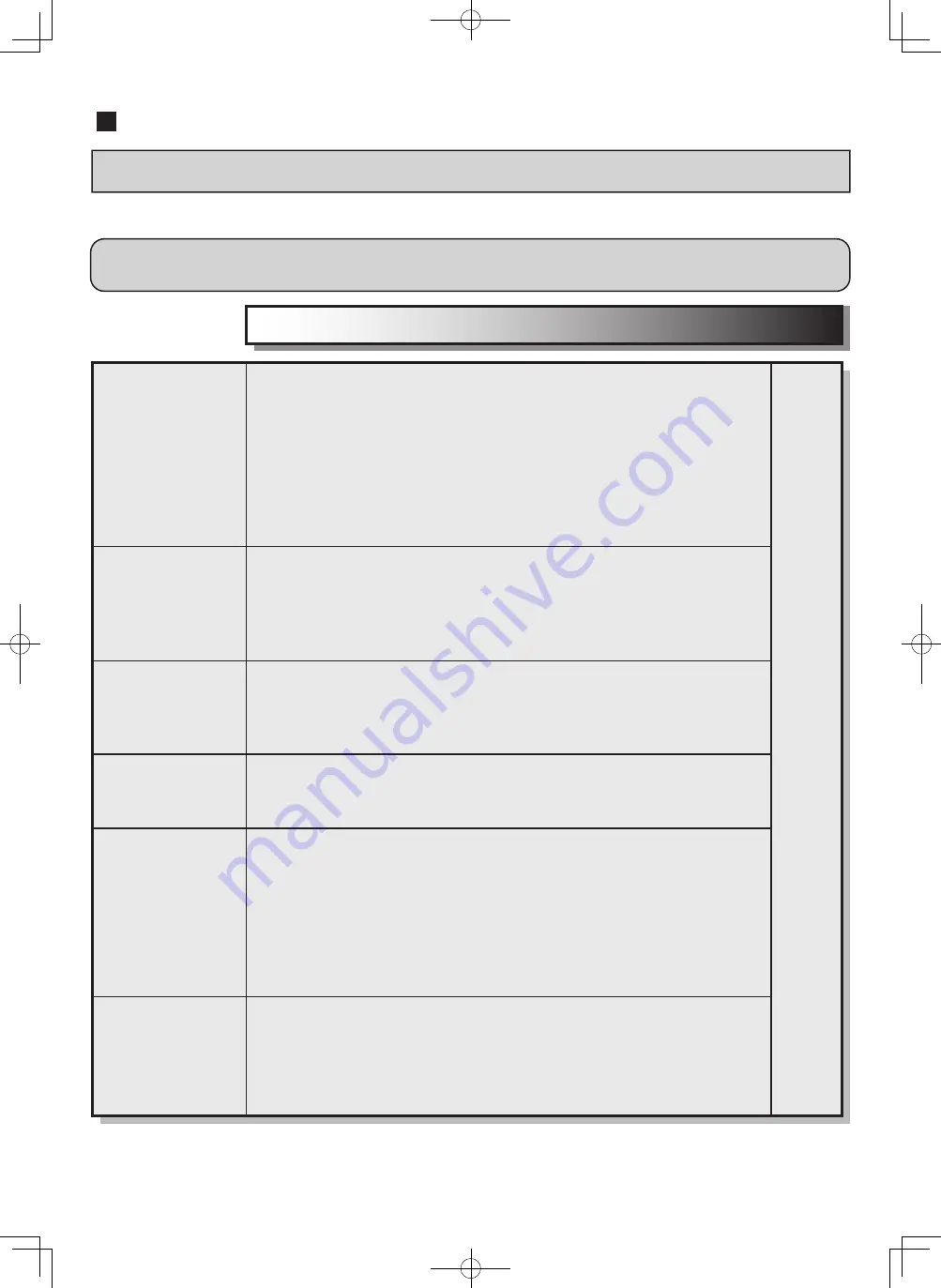

A title

Check day

Y D M

The check

person in

charge

Name

Contents of inspection

Remedy

※

Result Measures

Inspection cycle (standard)

Tro-Reel unit

Check to see if there is any foreign particles

adhering on its sliding surface or if it is seriously contaminated?

Clean with a specific purpose cleaner or waste

cloth.

Once

every

3 to 6

months

Is there any ark generated protrusion on its

sliding surface?

Remove any protrusion (convex) on the arc

scratch using a file.

Is there damage and crack at the insulating

sheath ?

When damage and crack occurred in the insulating

sheath of the duct, please change the duct.

○

Is there sharpen at the insulating sheath ?

When thickness of the insulating sheath is equal

to or less than 1.2mm, please change the duct.

Is the duct installed in parallel for a rail?

Please adjust the duct so that it is parallel at a rail.

○

Isn’t the unit dislocated from the hanger?

Review for any dislocated position on the unit.

Correct if any.

○

Are not there remarkable torsion and the curve of the duct? Please revise turning remarkable torsion.

○

○

○

Fixed end

insulator

︵

witho

ut bo

lt

︶

Are not there the cracks and damaged on a

resin part?

When damage and crack occurred in the fixed

end insulator, please change it.

○

Do stop it i in an insulating tape?

Please install an insulating tape.

○

Fixed end

insulator

︵

with bolt

︶

Are not there the cracks and damaged on a

resin part?

When damage and crack occurred in the fixed

end insulator, please change it.

○

Is’t there the slack of the lock bolt?

Retighten

○

Is not there the torsion?

Please revise torsion.

○

Is not there the exposure of the conductor?

Please install a repair cover for sheaths

○

End tension insulator

Is the coil spring set definitely?

Length of the coil spring L =115-125mm

L

Please adjust it to reasonable length

When tighten the duct, Please tighten a nut of

the tightening bolt with balancing in turn.

○

Does not a nut (a double nut) of the coil spring

part have the slack?

Retighten

○

Does not a bolt for electric wire connection of

the feeding-in terminal part have the slack?

Retighten

○

Are not there the cracks and damaged on a resin part? When damage and crack occurred in it, please change it.

○

Are not there a loser of the cover part, the falling off? When loser and the falling off occurred, confirm

the state of the cover, and please install the cover.

○

Is not there the exposure of the conductor?

Please install a repair cover for sheaths

○

Is not there the torsion?

Please revise torsion.

○

Center

fixed

insulator

Are not there the cracks and damaged on a

resin part?

When damage and crack occurred in it, please

change it.

○

Are not there a loser of the cover part, the falling off? Please install the cover.

○

Joiner

Isn’t there the conductor of the joint have a gap and the step? Please revise a gap, the step.

○

Isn’t there the slack of the connection bolt?

Retighten (tightening torque 6.9

〜

7.9N

・

m)

○

Are not there the cracks and damaged on a

resin part?

When damage and crack occurred in it, please

change it.

○

Are not there a loser of the cover part, the falling off? Please install the cover.

○

Ambient temperature

L

the case of less than 10℃ 115mm

the case of 11℃〜 40℃

125mm

Amount of wear of the conductor is correct?

Amount of wear of the conductor o

:

0.5 mm or less

Don't the insulated sheath and the resin part

of collector spinning shaft touch?

If it exceeds a threshold amount of wear, please replace the main conductor

In case of wearing down to the replacement indication line at next inspection,

please replace earlier than usual.

Check the amount of wear of the collector and

conductor of the duct,replace it if necessary.

○:Exchange required

Measures

●:Finished with exchange

△:Adjustment required

▲:Finished with adjustment

Result

○:Normal

×:Abnormality

・

Inspections item at the time of the pre-use test run(Checking at periodic inspection).

・

For using safely, please inspect the system one month after starting regular

operation.

・

The inspection cycle is mentioned below. However, determine your own

inspection cycle based on the actual operating rate and environmental condition.

・

Items in bold: Inspection items requiring particular attention.

Notes

<

To Maintenance manager

>