ー 44 ー

ー 45 ー

Name

Contents of inspection

Remedy

※

Result Measures

Inspection cycle (standard)

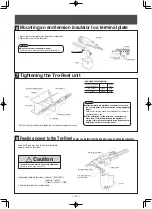

Collector arm

Is installation dimensions H of the collector

arms

collector arm mount rod

sliding surface

H

Please correct so that the distance H

is set to 95mm(Central value of the

collector arm permitted movable range

± 20mm) between the conductor sliding

surface and collector arm mount rod.

Please measure H size, where the

collector shoes is touched in the hanger.

○

Once

every

1 to 3

months

Does not the collector arm mount rod

have the remarkable torsion?

Torsion

When there is remarkable torsion, please

revise the collector arm.

○

Does not the collector shoes have the

outbreak such as Bali?

Please remove it with sandpaper.

Is there any serious wear to replacement

indication line.

Rplacement

indication line

Collector shoes should be replaced

when they partially wear down to the

replacement indication line.

Please exchange the collector shoes

ahead of time when it will be worn out

to the replacement indication line by the

time of the next check.

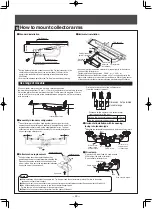

The center of the both sides of the

collector arm attachment and Tro-Reel

unit arranges.

Tro-Reel unit

Collector arm

attachment

Please revise it so that the center

matches.

○

Is there any ark generated protrusion ?

Remove the protrusion (convex) on the

arc scratch using a file.

Is there any mounting nut loosen?

Retighten

○

Is there any curve or variation on the arm? Replace the arm if there is curve or variation.

Is there any chip or broken?

Replace if chip or broken spring pin is found.

Is there any wear or hole loosen on spring

bearing metal?

Replace the collector shoes if there is

wear to replacement indication line.

Is there any damage on the sheath of lead wire? If there is damage, replace the collector shoes.

○

Is the collector shoes pulled by the lead

Are there abnormal wear?

wire?

If the collector shoes pulled, correct to

If there is abnormal wear of the arm,

replace the collector arm.

have extra length on lead wire.

○

○

Collector arm

support parts

for transverse

Are there modification of a spring (6.2mm or more

clearance between the spring) or rust on the spring?

Deformation of the spring, if there is

rust, replace

Is there a loose the screws?

Tighten screws more.

○

10

Name

Contents of inspection

Remedy

※

Result Measures

Inspection cycle (standard)

Center feed-in

joiner

Isn’t there the slack of a bolt for electric

wire connection of the feeding-in joiner ?

Retighten

○

Once

every

3 to 6

months

Are not there the cracks and damaged

on a resin part?

When damage and crack occurred in it,

please change it.

○

Are not there a loser of the cover part,

the falling off?

Please install the cover.

○

Hanger

Is the hanger installation pace equal to

or less than 4m?

Please install a hanger to become equal

to or less than 4m.

○

As for the curve department and the

hanger installation of both ends of the

terminal tightening insulator, is the pace

equal to or less than 500mm?

Please install a hanger to become equal

to or less than 500mm.

○

Is not there the slack of the installation

bolt?

Retighten

○

Are not there the cracks and damaged

on a resin part?

When damage and crack occurred in it,

Please change it.

○

Intermediate

tension

insulator

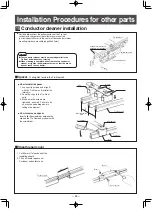

Is the center fixed insulator attached so

that the gap between the ducts may be

set to 15mm ± 5mm?

Please adjust so that the gap between

the ducts is set to 15mm ± 5mm.

○

Is the coil spring set definitely?

Length of the coil spring L =115-

125mm

L

Please adjust it to reasonable length.

Ambient temperature

L

the case of less than 10℃

115mm

the case of 11℃~ 40℃

125mm

○

Does not a nut (a double nut) of the coil

spring part have the slack?

Retighten

○

Isn’t there the slack of a bolt for electric

wire connection of the feeding-in joiner ?

Retighten

○

Are not there the cracks and damaged

on a resin part?

When damage and crack occurred in it,

Please change it.

○

Are not there a loser of the cover part,

the falling off?

Please install the cover.

○

Insulating

piece

Are not there the cracks and damaged

on a resin part?

When damage and crack occurred in it,

Please change it.

○

Are not there a loser of the cover part,

the falling off?

Please install the cover.

○

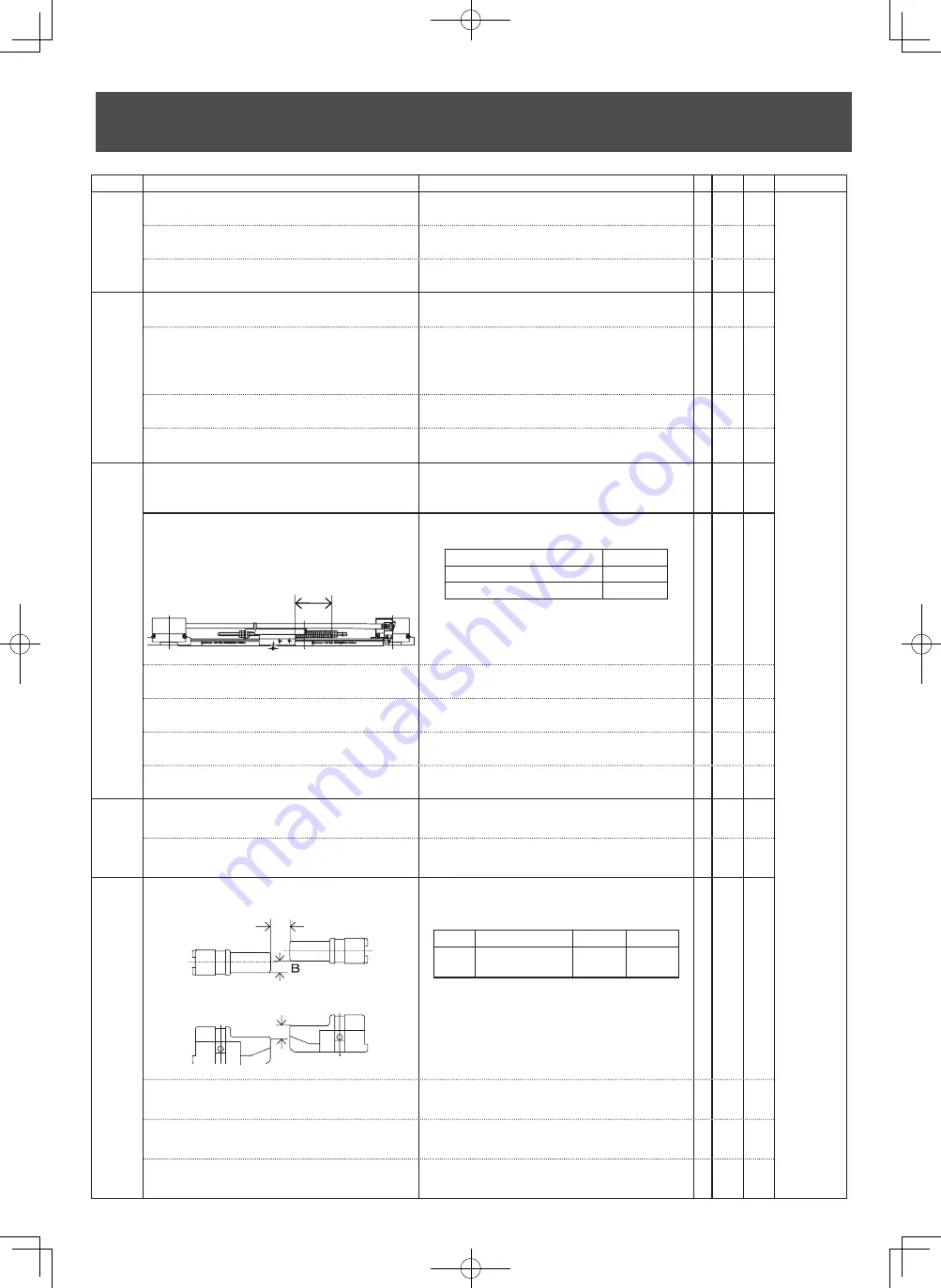

Guide cap

A r e t h e i n s t a l l a t i o n d i m e n s i o n s

clearance?

A

C

Please revise it to dimensions in the

clearance

A

B

C

length 10 ~ 30mm

5mm

lower

7mm

lower

○

Are not there a loser of the cover part,

the falling off?

Please install the cover.

○

D o e s n o t t h e r e s i n p a r t h a v e t h e

abrasion?

When I am worn, please change

Are not there the cracks and damaged

on a resin part?

When damage and crack occurred in it,

Please change it.

○