ー 40 ー

ー 41 ー

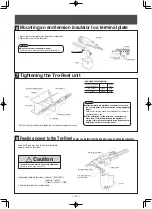

approx.500

4000 or less (standard)

500 or less

500 or less

4000 or less

(standard)

500 or less

●

End tension insulator (with feed-in terminal)

Applies tension to the Tro-Reel unit to absorb

sag or expansion and contraction due to

temperature fluctuation.

It supplies a power supply from here.

●

Spacer

If there are no hangers available near the end tension

insulator, attach a spacer, making sure that the

Tro-Reel unit is not tilted.

●

Tro-Reel unit

AC 600V, 60A, 150A, 200A, and 300A.

Standard length is 100m/coil. 80m, 60m,

40m, and 10m coils are also available.

●

Standard hanger (JAPANESE

Regulations on Electrical

Installation, Article 199)

Fix properly so that the Tro-Reel unit

won’t deflect.Use hanger with insulators

for outdoor.and use hanger with porcelain

insulator for sea side areas use or bad

environmental areas.

●

Bracket (not included)

Use a L-shape bracket of 40mm

×

40mm

×

5mm or larger.

Brackets should be positioned at an interval of 4m or less

for straight sections and 0.5m or less for curved sections.

●

Horizontal mounting distance is 2m or less.

●

For a standard mounting, distance at a heavily vibrating

position or outdoor is 2m or less distance.

●

Center fixed insulator

When part of the Tro-Reel unit is installed on a horizontal

curve, it should be attached at the joint between the curved

section and the straight section to maintain tension in the

straight section.

●

Fixed end insulator (with bolt)

Fixes one end of the Tro-Reel unit for easy

tension application during installation.

The insulator should be mounted to the same

type of bracket as used with the end tension

insulator (with feed-in terminal).

●

Fixed end insulator

Fixes one end of the Tro-Reel unit for easy

tension application during installation.

Drill a hole in the end of the Tro-Reel unit

and put a pin through the hole.

●

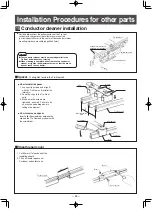

Collector arm

●

Traveling speed is 300m /min. or lower.

●

For a tandem configuration,easily assemble it at

the job site if you use two collector arms.

●

If you use on a horizontal run way, set a

Collector arm support parts(for transverse).

(Collector arm mount rod (25

×

25mm) is not

included.)

Instllation Procedure

Unit : mm

●

If the installation length exceeds 50m,

use end tension insulators on both ends.

Notes

●

If the installation length exceeds 50m,

use end tension insulators at both ends.

●

When a hanger with the porcelain

insulator is used,use fix end

insulators(with bolt).

Notes

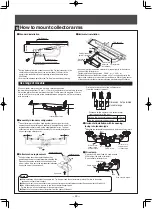

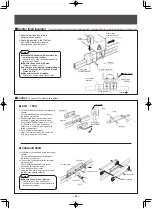

Standard Installation Procedures for Tro-Reel

Installation Procedures for Tro-Reel unit and hanger supporting distance

Hanger types

Standard hanger

Hanger with insulator

A size

Minimum Standard

B size

B

1

B

2

B

3

Size

75

100

95

135

295

160

320

Tro-Reel unit mounting method and hanger intervals.

Hanger

intervals

Standard

installation

Horizontal

installation

4m or less

2m or less

Note: The B

3

size is applied for a L-shape bracket of 40mm

×

40mm

×

5mm.

When installed

outdoors or in a

place exposed to

heavy vibration such

as for horizontal

wiring in cranes:

2m or less

●

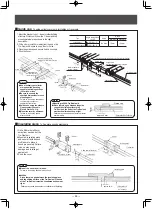

Standard installation

A

Collector arm

mount rod, 25

×

25mm

(not included)

A

25

25

※

B

2

B

1

●

Two-stage installation

A

A

B

2

B

1

B

3

B

2

B

1

※

※

●

Horizontal installation

A

A

40mm or more

B

1

B

2

※

The asterisk (

※

) indicates the conductor sliding surface.

Installation size (mm)

(mm)

The following drawing shows the dimensions for mounting

Ⅰ

-beams and other building structures, support brackets(not

included) and Tro-Reel unit to

Ⅰ

-beams and other building

structure.

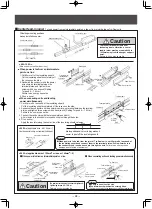

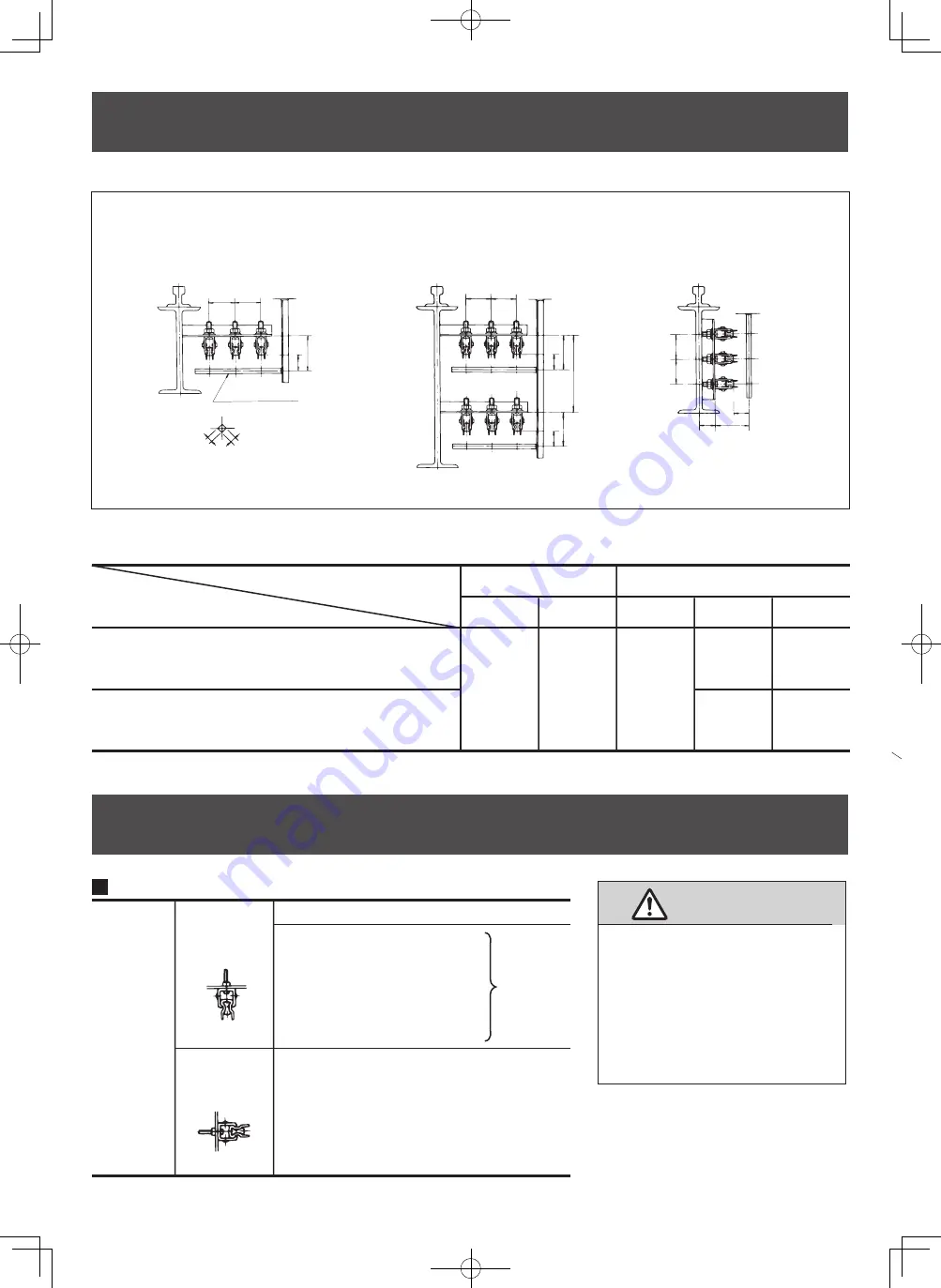

Do not step on or bang the Tro-Reel unit on

the ground to straighten.

The insulating sheath of Tro-Reel unit is made of

rigid PVC, which becomes fragile and stiffen

under low temperatures. As this may damage the

unit. Use a straightener to straighten the coils

before installation. Failure to do so may cause

poor collector arm contact or separation from

wires.

Caution