CONTENTS

SAFETY PRECAUTIONS..........................................................................................................................................................2

SERVICE HINTS .......................................................................................................................................................................3

ADJUSTMENT PROCEDURE AND FACTORY SETTINGS .....................................................................................................4

WAVEFORM PATTERN TABLE ...............................................................................................................................................5

ALIGNMENT SETTINGS...........................................................................................................................................................6

BLOCK DIAGRAMS ..................................................................................................................................................................7

PARTS LOCATION .................................................................................................................................................................12

REPLACEMENT PARTS LIST ................................................................................................................................................13

SCHEMATIC DIAGRAMS .......................................................................................................................................................44

CONDUCTOR VIEWS.............................................................................................................................................................55

SAFETY PRECAUTIONS

GENERAL GUIDE LINES

1. It is advisable to insert an isolation transformer in the

a.c. supply before servicing a hot chassis.

2. When servicing, observe the original lead dress in the

high voltage circuits. If a short circuit is found, replace

all parts that have been overheated or damaged by

the short circuit.

3. After servicing, see that all the protective devices

such as insulation barriers, insulation papers, shields

and isolation R-C combinations are correctly

installed.

4. When the receiver is not being used for a long period

of time, unplug the power cord from the a.c. outlet.

5. Potentials as high as 33kV are present when this

receiver is in operation. Operation of the receiver

without the rear cover involves the danger of a shock

hazard from the receiver power supply. Servicing

should not be attempted by anyone who is not

familiar with the precautions necessary when working

on high voltage equipment. Always discharge the

anode of the tube.

6. After servicing make the following leakage current

checks to prevent the customer from being exposed

to shock hazard.

LEAKAGE CURRENT COLD CHECK

1. Unplug the a.c. cord and connect a jumper between

the two prongs of the plug.

2. Turn on the receiver’s power switch.

3. Measure the resistance value with an ohmmeter,

between the jumpered a.c. plug and each exposed

metallic cabinet part on the receiver, such as screw

heads, aerials, connectors, control shafts etc. When

the exposed metallic part has a return path to the

chassis, the reading should be between 4M ohm and

20M ohm. When the exposed metal does not have a

return path to the chassis, the reading must be

infinite.

LEAKAGE CURRENT HOT CHECK

1. Plug the a.c. cord directly into the a.c. outlet. Do not

use an isolation transformer for this check.

2. Connect

a

2k

Ω

10W resistor in series with an

exposed metallic part on the receiver and an earth,

such as a water pipe.

3. Use an a.c. voltmeter with high impedance to

measure the potential across the resistor.

4. Check each exposed metallic part and check the

voltage at each point.

5. Reverse the a.c. plug at the outlet and repeat each of

the above measurements.

6. The potential at any point should not exceed

1.4V rms. In case a measurement is outside the limits

specified, there is a possibility of a shock hazard, and

the receiver should be repaired and rechecked before

it is returned to the customer.

X-RADIATION WARNING

1. The potential sources of X-Radiation in TV sets are

the high voltage section and the picture tube.

2. When using a picture tube test jig for service, ensure

that the jig is capable of handling 33kV without

causing X-Radiation.

NOTE: It is important to use an accurate periodically

calibrated high voltage meter.

1. Set the brightness to minimum.

2. Measure the high voltage. The meter should indicate.

30.5kV ± 1kV (28”) , 32kV ± 1kV (32”/36”).

If the meter indication is out of tolerance, immediate

service and correction is required to prevent the

possibility of premature component failure.

3. To prevent any X-Radiation possibility, it is essential

to use the specified tube.

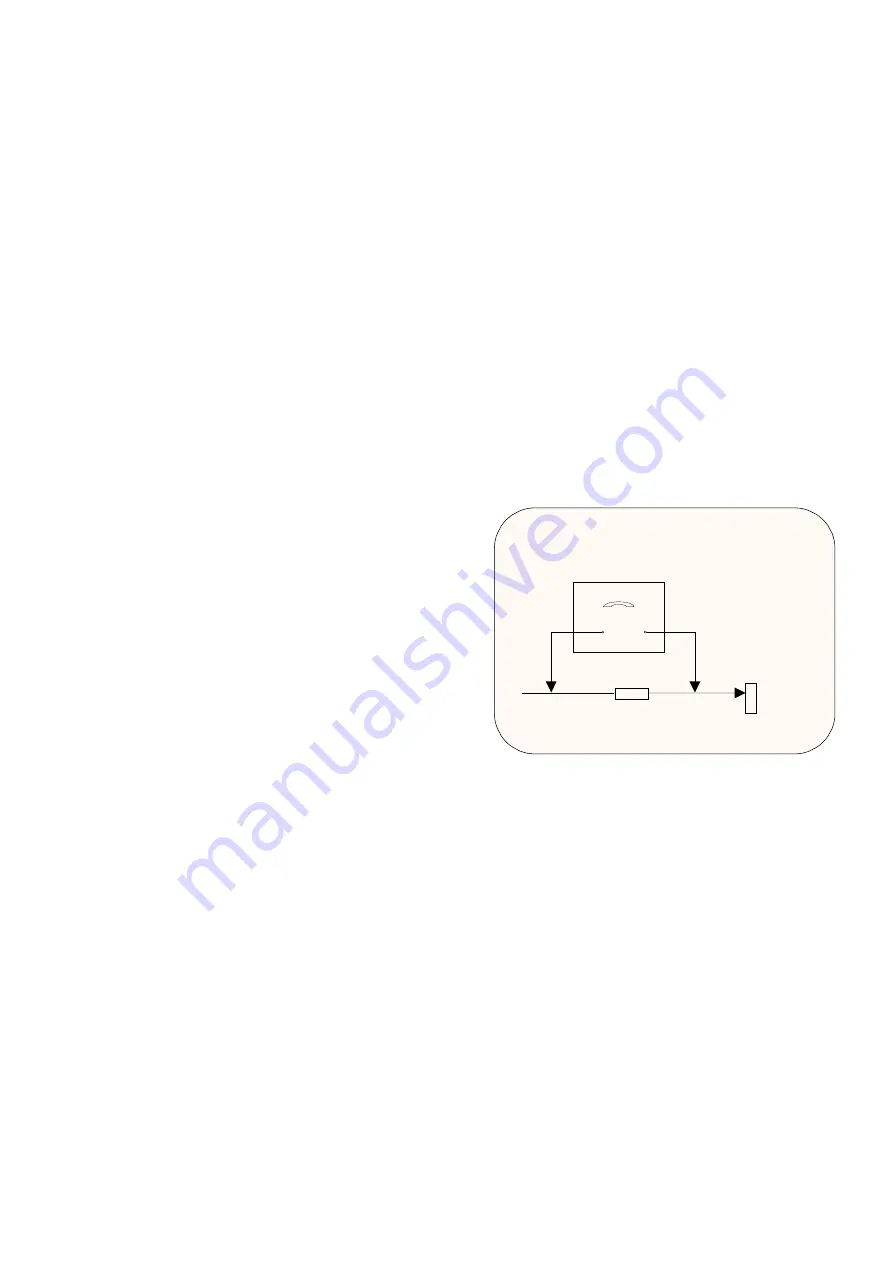

HOT CHECK CIRCUIT

a.c. VOLTMETER

WATER PIPE

(EARTH)

TO INSTRUMENT’S EXPOSED

METALLIC PARTS

Fig. 1.

2k

Ω

10 Watts

2

Summary of Contents for TX-28PB50F

Page 8: ...8 ...

Page 9: ...9 ...

Page 10: ...10 ...

Page 11: ...11 ...

Page 12: ...12 ...

Page 45: ......

Page 46: ......

Page 47: ......

Page 48: ......

Page 49: ......

Page 50: ......

Page 51: ......

Page 52: ......

Page 53: ......

Page 54: ......

Page 55: ......

Page 56: ......

Page 57: ...A BOARD TNPH0348 55 ...

Page 58: ...A BOARD TNPH0348 56 ...

Page 59: ...D DOARD TNPH0349 57 ...

Page 60: ...DF BOARD TNPA1806 ...

Page 61: ...DIODES D1011 A2 D1012 A2 D3103 B2 D3104 B2 TRANSISTORS Q1003 A2 2 1 A B G BOARD TNP8EG004 58 ...

Page 62: ...L BOARD TNPA1726 59 ...

Page 63: ...H BOARD TNPA1724 60 ...

Page 65: ...62 NOTES ...