EN

FR

DE

IT

PT

GR

ES

3

Big̲PAC̲eng.indb 3

2011/02/23 13:37:46

Big̲PAC̲eng.indb 4

2011/02/23 13:37:46

5

Precautions for Installation Using New

Refrigerant

1. Care regarding tubing

1-1. Process tubing

●

Material: Use C1220 phosphorous deoxidized copper

specified in JIS H3300 “Copper and Copper Alloy Seamless

Pipes and Tubes”.

●

Tubing size: Be sure to use the sizes indicated in the

table below.

●

Use a tube cutter when cutting the tubing, and be sure to

remove any flash. This also applies to distribution joints

(optional).

●

When bending tubing ø15.88 or smaller, use a bending

radius that is 4 times the outer diameter of the tubing or

larger.

CAUTION

Use sufficient care in handling the tubing. Seal the tubing

ends with caps or tape to prevent dirt, moisture, or other

foreign substances from entering. These substances can

result in system malfunction.

Unit: mm

Material

O

Copper tube

Outer diameter

6.35

9.52

12.7

15.88

Wall thickness

0.8

0.8

0.8

1.0

Material

1/2 H, H

Copper tube

Outer diameter

19.05

22.22

25.4

28.58

Wall thickness

1.0

1.0

1.0

1.0

1-2. Prevent impurities including water, dust and oxide from

entering the tubing. Impurities can cause R410A refrigerant

deterioration and compressor defects. Due to the features

of the refrigerant and refrigerating machine oil, the

prevention of water and other impurities becomes more

important than ever.

2. Be sure to recharge the refrigerant only in liquid form.

2-1. Since R410A is a non-azeotrope, recharging the refrigerant

in gas form can lower performance and cause defects of

the unit.

2-2. Since refrigerant composition changes and performance

decreases when gas leaks, collect the remaining

refrigerant and recharge the required total amount of new

refrigerant after fixing the leak.

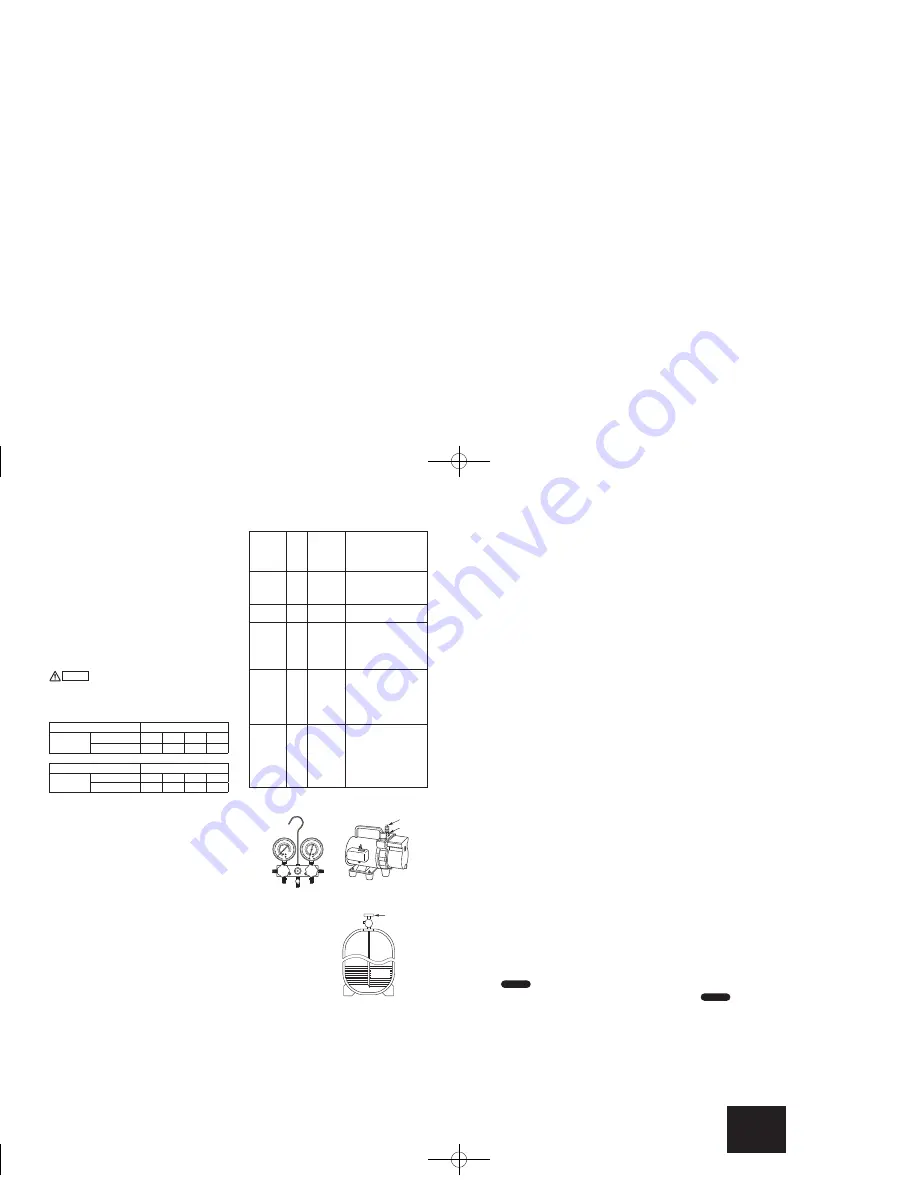

3. Different tools required

3-1. Tool specifications have been changed due to the

characteristics of R410A.

Some tools for R22- and R407C-type refrigerant systems

cannot be used.

Item

New

tool?

R407C

tools

compatible

with

R410A?

Remarks

Manifold

gauge

Yes

No

Types of refrigerant,

refrigerating machine oil,

and pressure gauge are

different.

Charge

hose

Yes

No

To resist higher pressure,

material must be changed.

Vacuum

pump

Yes

Yes

Use a conventional vacuum

pump if it is equipped with

a check valve. If it has no

check valve, purchase and

attach a vacuum pump

adapter.

Leak

detector

Yes

No

Leak detectors for CFC

and HCFC that react to

chlorine do not function

because R410A contains

no chlorine. Leak detectors

for HFC134a can be used

for R410A.

Flaring oil

Yes

No

For systems that use R22,

apply mineral oil (Suniso

oil) to the flare nuts on the

tubing to prevent refrigerant

leakage. For machines

that use R407C or R410A,

apply synthetic oil (ether

oil) to the flare nuts.

* Using tools for R22 and R407C and new tools for R410A

together can cause defects.

3-2. Use R410A exclusive cylinder only.

Single-outlet valve

(with siphon tube)

Liquid refrigerant should be

recharged with the cylinder

standing on end as shown.

Manifold gauge

Vacuum pump

Outlet

Inlet

Valve

Liquid

Big̲PAC̲eng.indb 5

2011/02/23 13:37:46

6

IMPORTANT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Please Read Before Starting

Check of Density Limit

Precautions for Installation Using New Refrigerant

1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-1.

Tools Required for Installation (not supplied)

1-2.

Accessories Supplied with Unit

1-3.

Type of Copper Tube and Insulation Material

1-4.

Additional Materials Required for Installation

1-5. Tubing

Size

2. SELECTING THE INSTALLATION SITE . . . . . . . . . . . . . . 8

2-1. Outdoor

Unit

2-2.

Air Discharge Chamber for Top Discharge

2-3.

Installing the Unit in Heavy Snow Areas

2-4.

Precautions for Installation in Heavy Snow Areas

2-5.

Dimensions of Snow / Wind-proof Ducting and

Refrigerant Tubing Space for Installation

3. HOW TO INSTALL THE INDOOR UNIT . . . . . . . . . . . . . . 10

■

High Static Pressure Ducted Type (E1 Type) . . . . . . . . . . . 10

3-1.

Required Minimum Space for Installation and Service

(8, 10 Types)

3-2.

Suspending the Indoor Unit

3-3.

Installing the Refrigerant Tubing

3-4.

Installing the Drain Pipe

4. HOW TO INSTALL THE OUTDOOR UNIT . . . . . . . . . . . . 12

4-1.

Installing the Outdoor Unit

4-2. Drainage

Work

4-3.

Routing the Tubing and Wiring

5. ELECTRICAL WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5-1.

General Precautions on Wiring

5-2.

Recommended Wire Length and Wire

Diameter for Power Supply System

5-3.

Wiring System Diagrams

6. HOW TO INSTALL THE TIMER REMOTE CONTROLLER

(OPTIONAL PART) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

N OT E

Refer to the Instruction Manual attached to the optional

Timer Remote Control Unit.

7. HOW TO PROCESS TUBING . . . . . . . . . . . . . . . . . . . . . 15

7-1.

Connecting the Refrigerant Tubing

7-2.

Connecting Tubing Between Indoor and

Outdoor Units

7-3.

Insulating the Refrigerant Tubing

7-4. Taping

the

Tubes

7-5.

Finishing the Installation

8. LEAK TEST, EVACUATION AND ADDITIONAL

REFRIGERANT CHARGE . . . . . . . . . . . . . . . . . . . . . . . . 19

■

Air Purging with a Vacuum Pump (for Test Run)

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8-1. Leak

Test

8-2. Evacuation

8-3.

Charging Additional Refrigerant

8-4.

Finishing the Job

9. TEST

RUN

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

9-1.

Preparing for Test Run

■

E1 Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

9-2. Caution

9-3.

Test Run Procedure

9-4.

Items to Check Before the Test Run

9-5.

Test Run Using the Remote Controller

9-6. Precautions

9-7.

Table of Self-Diagnostic Functions and

Corrections (E1 Type)

9-8. System

Control

9-9.

Test Run Procedure

9-10. Items to Check Before the Test Run

9-11. Preparation for Test Run

9-12. Test

Run

9-13. Precautions

9-14. Table of Self-Diagnostic Functions and Corrections

9-15. System

Control

■

E1 Type (for Link Wiring) . . . . . . . . . . . . . . . . . . . . . . . . . . 32

9-16. Caution

9-17. Test Run Procedure

9-18. Items to Check Before the Test Run

9-19. Test Run Using the Remote Controller

9-20. Table of Self-Diagnostic Functions and

Corrections (E1 Type)

9-21. Automatic Address Setting

9-22. Automatic Address Setting

9-23. Caution for Pump Down

10. HOW TO INSTALL WIRELESS REMOTE

CONTROLLER RECEIVER . . . . . . . . . . . . . . . . . . . . . . . 40

N OT E

Refer to the Instruction Manual attached to the optional

Wireless Remote Controller Receiver.

11. MARKINGS FOR DIRECTIVE

97/23/EC (PED) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

12. APPENDIX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

CONTENTS

Page Page

Big̲PAC̲eng.indb 6

2011/02/23 13:37:46

B

ig

̲P

A

C

̲e

n

g

̲m

en

tu

k

e.i

n

d

d

3

Big̲PAC̲eng̲mentuke.indd 3

2

0

1

1

/0

2

/2

3

1

3

:4

3

:3

3

2011/02/23 13:43:33

Summary of Contents for U-200PE1E8

Page 2: ......

Page 24: ... NOTE EN FR DE IT PT GR ES 22 ...

Page 46: ... NOTE 44 GB FR DE IT PT GR ES SUPPLEMENT ...

Page 68: ... ANMERKUNGEN 66 GB FR DE IT PT GR ES SUPPLEMENT ...

Page 90: ... PROMEMORIA 88 GB FR DE IT PT GR ES SUPPLEMENT ...

Page 112: ...EN FR DE IT PT GR ES 110 NOTAS ...

Page 134: ... Σημεıωματάριο 132 GB FR DE IT PT GR ES SUPPLEMENT ...

Page 156: ...EN FR DE IT PT GR ES 154 NOTAS ...

Page 157: ......