3

- 34

2WAY SYSTEM

Outdoor Unit Repair Procedures

3

9. Compressor

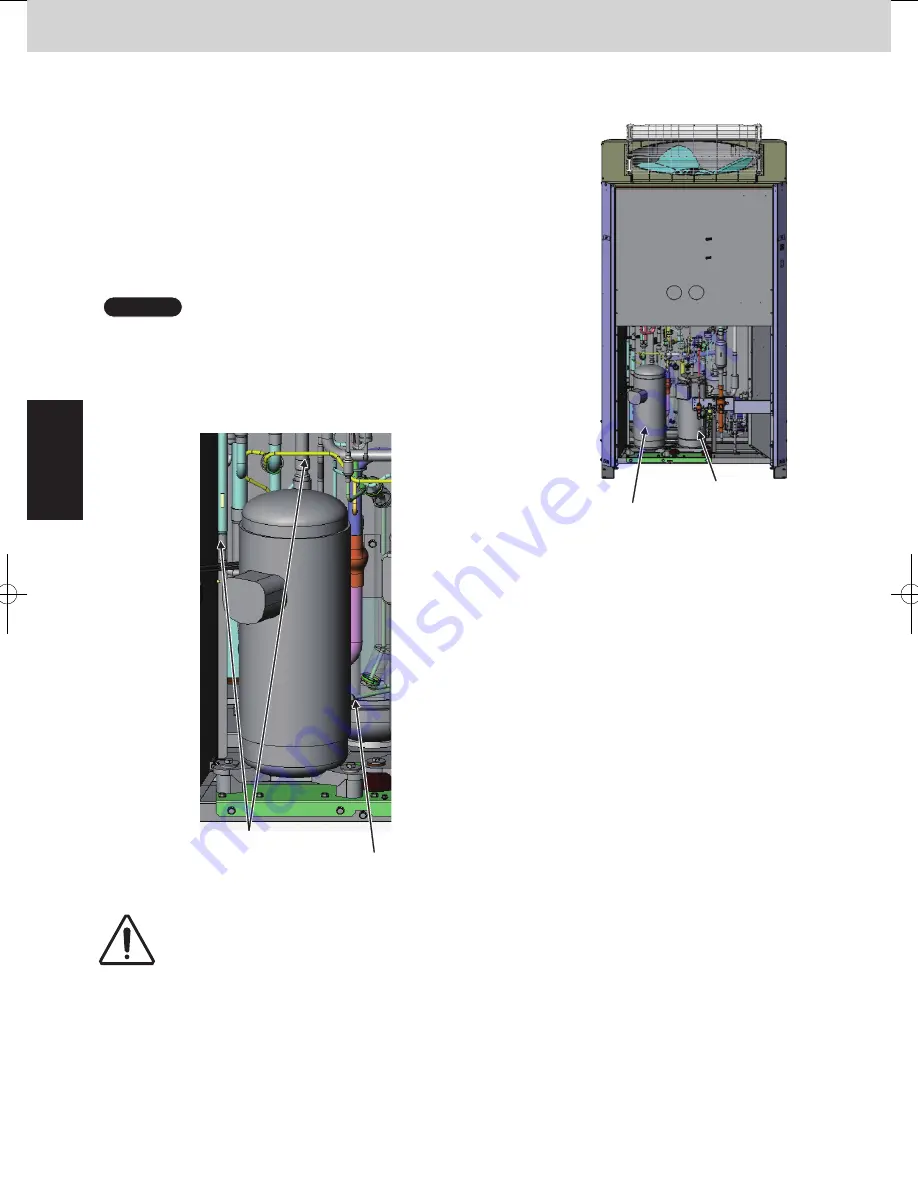

9-3-2. Removing Constant-Speed Compressors (for model 12, 14 and 16 horsepower)

(1) After retrieving refrigerant from the system, perform nitrogen gas

replacement on the service port of the gas side service valve.

(2) Remove the insulator that the compressor is surrounded.

(3) Remove the lid on the compressor terminal plate.

Then disconnect the power cablel and discharge sensor.

(5) Remove the bolts (3 locations) on the foot of the compressor.

Then remove the washers and rubber spacers.

(6) Disconnect the tube-with-flare-nut for the constant-speed compressor.

Tube-with-flare-nut

(8) Pull the compressor toward you.

(4) Remove the crankcase heater.

Protect the sensors and the surrounding

plates, rubber, lead wires, clamps, and

other items.

CAUTION

NOTE

If oil remaining in the compressor reaches the equalized

oil level, oil will come pouring out. Cover the tube in place

with waste cloth while watching out for oil leaks.

Then cap the disconnected tube and mount the flare nut

on the compressor. Tighten the flare nut with a seal

bonnet (1/4") in it.

(7) Remove the welded parts (2 locations) as shown in the figure.

Model 12, 14 and 16HP

(show for model 14, 16HP)

INV compressor

Constant-speed compressor

Constant-Speed Compressor

Welded parts (2 locations)

SM830204-05_2WAY SYS_new.indb 34

15/01/05 15:31:41

Summary of Contents for U-20ME1E81

Page 54: ... MEMO 1 46 ...

Page 102: ... MEMO 3 36 ...

Page 116: ... MEMO 4 14 ...

Page 177: ...201502 ...